What is smooth sanding?

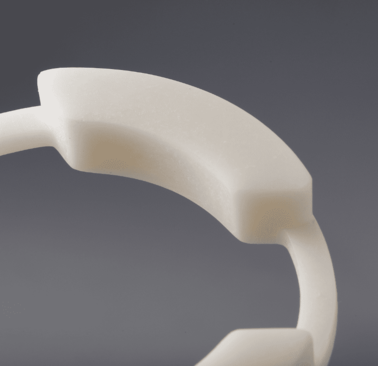

Smooth sanding is a meticulous process of refining and polishing surfaces. It involves using progressively finer grits of sandpaper to remove imperfections, layer lines, and rough textures.

By starting with a coarser grit and gradually moving to finer ones, the surface becomes increasingly smooth and polished.

Smooth sanding enhances the material's aesthetic appeal and prepares it for further finishing steps, such as painting or coating, ensuring a high-quality, professional result.