3D printed components' mechanical properties vary depending on build orientation, layer adhesion, and process parameters. The anisotropy means that design decisions directly influence strength outcomes. Engineers must therefore consider not only material selection but also geometry, orientation, and process–design interactions when targeting specific mechanical properties.

This article explains how design impacts the key strength-related properties of 3D printed parts, including tensile, flexural, compressive, impact, and fatigue resistance, before exploring design parameters and strategies that enhance performance across various 3D printing processes.

Tensile Strength

What is it?

Tensile strength is the maximum stress a material can withstand while being stretched before failure. In 3D printing, tensile performance is strongly influenced by anisotropy: parts are typically stronger along the layer plane and weaker across layers. Build orientation, infill density, and wall thickness all play critical roles.

Example

A tensile bar printed in FDM with 100% infill and aligned layers can achieve up to 70–80% of the bulk polymer’s tensile strength. The same geometry printed vertically may fail at less than half that value due to weak interlayer adhesion. In metal AM, tensile strength can approach wrought values if post‑processed with hot isostatic pressing (HIP).

Flexural Strength

What is it?

Flexural strength measures a material’s ability to resist deformation under bending loads. For 3D printed parts, this property is sensitive to layer bonding, geometry, and surface finish. Weak interlayer adhesion or rough surfaces can cause premature delamination or crack initiation.

Example

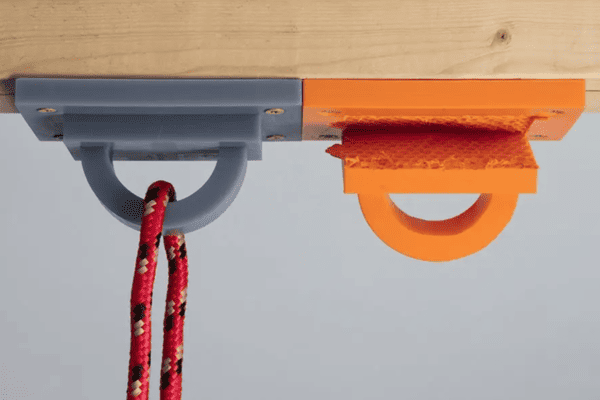

An SLA printed beam often demonstrates higher flexural strength than an FDM counterpart due to isotropic curing, though it may be brittle. In contrast, a topology‑optimized metal bracket produced via SLM can achieve flexural performance comparable to machined aluminum once post‑processed.

Image Copyright © 3DSPRO Limited. All rights reserved.

Compressive Strength

What is it?

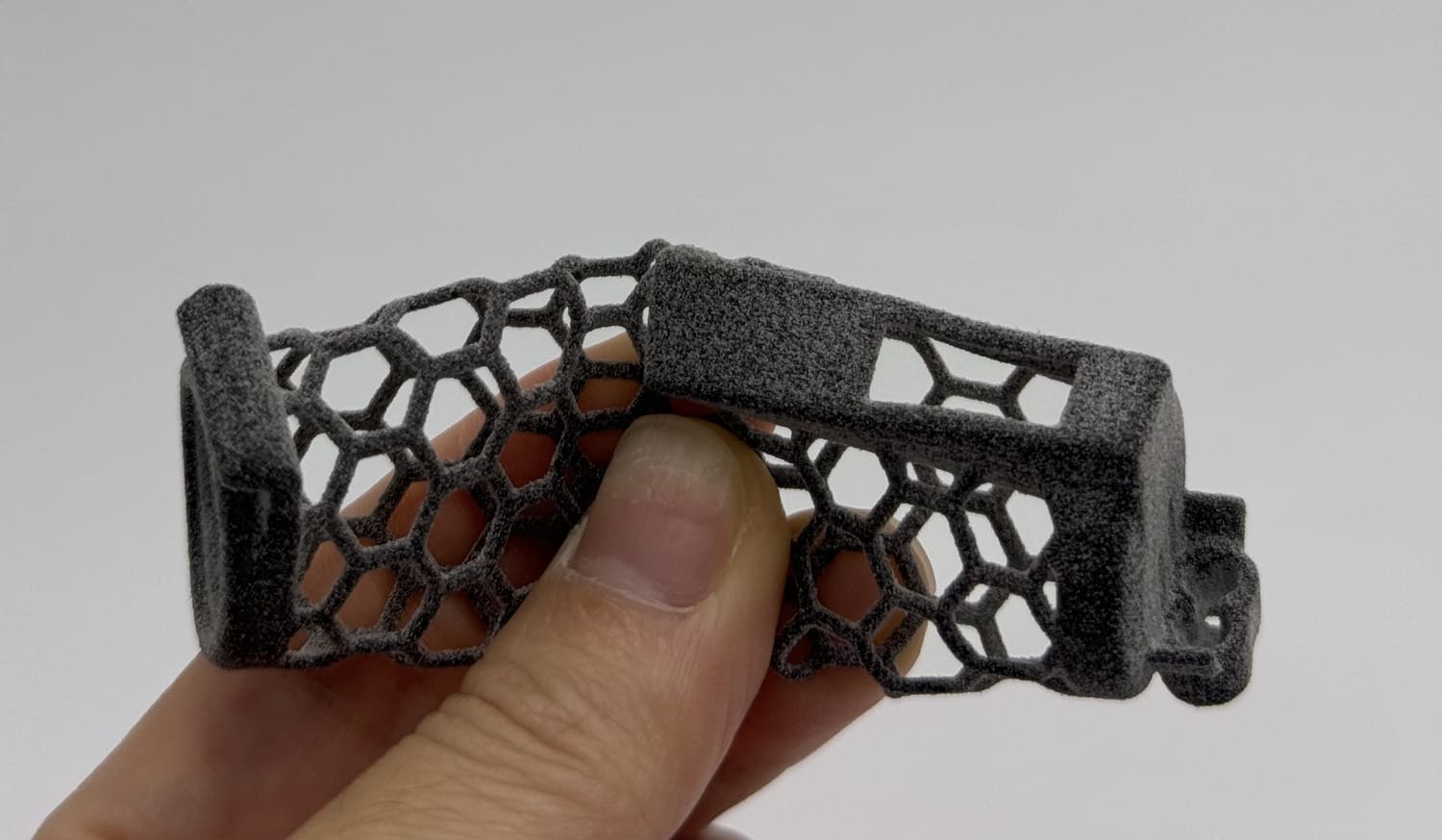

Compressive strength is the capacity of a material to withstand loads that reduce its size. In AM, compressive performance is influenced by infill pattern, wall thickness, and build orientation. Lattice and cellular designs are particularly relevant, as they can be tuned for energy absorption.

Example

A gyroid infill structure in polymer AM can sustain high compressive loads relative to its weight, making it suitable for protective padding. In biomedical applications, porous titanium implants produced by EBM are designed to balance compressive strength with bone‑like elasticity.

Impact Strength

What is it?

Impact strength measures a material’s ability to absorb energy during sudden loading without fracturing. It is critical for applications where a shock or collision is expected. In AM, impact resistance is often limited by poor interlayer adhesion or brittle materials.

Example

An SLA resin part may fracture under a drop test due to brittleness, while a carbon‑fiber reinforced FDM component can absorb significantly more energy. Rounded corners and fillets in the design further improve impact resistance by reducing stress concentration.

Fatigue Resistance

What is it?

Fatigue resistance is the ability of a material to withstand cyclic loading without failure. For AM parts, fatigue life is often reduced by surface roughness, porosity, and anisotropy. Crack initiation typically occurs at layer ridges or voids.

Example

A metal AM turbine blade subjected to cyclic stresses may fail prematurely if left as‑built. However, post‑processing such as polishing or HIP can extend fatigue life to levels comparable with conventionally manufactured blades. In polymers, aligning layers with the principal stress direction significantly improves fatigue resistance.

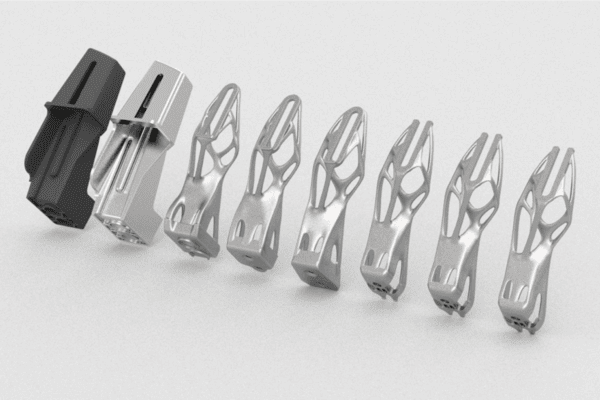

Image Copyright © 3DSPRO Limited. All rights reserved.

Design Parameters Affecting Strength

1. Geometry and Topology Optimization: Lattice structures reduce weight but must be designed to avoid stress concentration. Topology optimization aligns material distribution with load paths.

2. Build Orientation: Determines anisotropy in polymers and grain structure in metals. Critical for aligning load-bearing features with stronger directions.

3. Layer Height and Resolution: Smaller layer heights improve interlayer adhesion in polymers and reduce defect size in metals.

4. Support Structures: Improper support design can induce residual stresses and distortions.

5. Infill Density and Pattern: Directly affects tensile, compressive, and impact strength.

Design Strategies for Enhanced Strength

1. Build Orientation Optimization

• Principle: Align critical load paths with the strongest material directions.

• Polymers (FDM, SLA, DLP):

Print tensile members in the XY plane to maximize interlayer bonding.

Avoid Z‑axis loading where delamination is most likely.

• Metals (SLM, EBM):

Orient parts to minimize unsupported overhangs and residual stress buildup.

Consider grain growth direction, as columnar grains can influence anisotropy.

• Composites: Align fiber reinforcement with principal stress directions for maximum benefit.

2. Geometry and Topology Optimization

• Topology Optimization:

Use computational tools to remove non‑load‑bearing material while maintaining stiffness.

Particularly effective in aerospace and automotive lightweighting.

• Lattice and Cellular Structures:

Gyroid, diamond, and honeycomb lattices balance weight reduction with compressive strength.

Must be tuned to avoid stress concentration at nodes.

• Shell‑Core Designs: Solid outer shells combined with lightweight lattice cores provide high strength‑to‑weight ratios.

3. Infill and Density Control

• Infill Density: Higher density increases tensile and compressive strength but adds weight and build time.

• Infill Pattern: Continuous patterns (e.g., gyroid) distribute stress more evenly than rectilinear or triangular infills.

• Gradient Infill: Variable density tailored to local stress regions improves efficiency.

4. Layer Height and Resolution

• Smaller Layer Heights:

Improve interlayer adhesion in polymers.

Reduce defect size in metals, lowering crack initiation risk.

• Trade‑off: Finer layers increase build time and cost, requiring a balance between performance and productivity.

5. Support Structure Design

• Mechanical Role: Supports not only stabilize overhangs but also influence residual stress distribution.

• Design Considerations:

Minimize contact area to reduce post‑processing damage.

Orient supports to avoid stress risers in critical load paths.

6. Post‑Processing Integration

• Heat Treatment: Relieves residual stresses and improves ductility in metals.

• Hot Isostatic Pressing (HIP): Eliminates porosity in metal AM, significantly improving fatigue resistance.

• Surface Finishing: Polishing, machining, or shot peening reduces surface roughness, delaying crack initiation.

• Infiltration and Coatings: Polymer infiltration (e.g., epoxy) or metallic coatings enhance strength and durability.

7. Material Selection and Reinforcement

• Reinforced Polymers: Carbon fiber, glass fiber, or Kevlar‑filled filaments improve tensile and flexural strength.

• High‑Performance Resins: Engineering‑grade SLA resins offer higher modulus and toughness.

• Metal Alloys: Nickel‑based superalloys and titanium alloys provide superior strength for aerospace.

• Multi‑Material Printing: Functionally graded materials allow localized reinforcement.

FAQs

Q: Why are 3D printed parts often weaker than traditionally manufactured parts?

A: Because of anisotropy, porosity, and weaker interlayer bonding. Proper design and post-processing can mitigate these issues.

Q: Which 3D printing process produces the strongest parts?

A: Metal AM processes such as SLM or EBM can achieve near-wrought strength when post-processed. For polymers, SLA and reinforced FDM composites offer high strength depending on the application.

Q: How does the infill pattern affect strength?

A: Dense or continuous patterns (e.g., gyroid) distribute stress more evenly, improving tensile and compressive strength compared to sparse or rectilinear infills.

Q: Can 3D printed parts be used in load-bearing applications?

A: Yes, provided that design, orientation, and post-processing are optimized. Aerospace, automotive, and medical industries already deploy AM parts in structural roles.

Q: What is the most critical design consideration for strength?

A: Build orientation, as it dictates anisotropy and interlayer bonding, is often the single most influential factor.