What is Topology Optimization in 3D Printing?

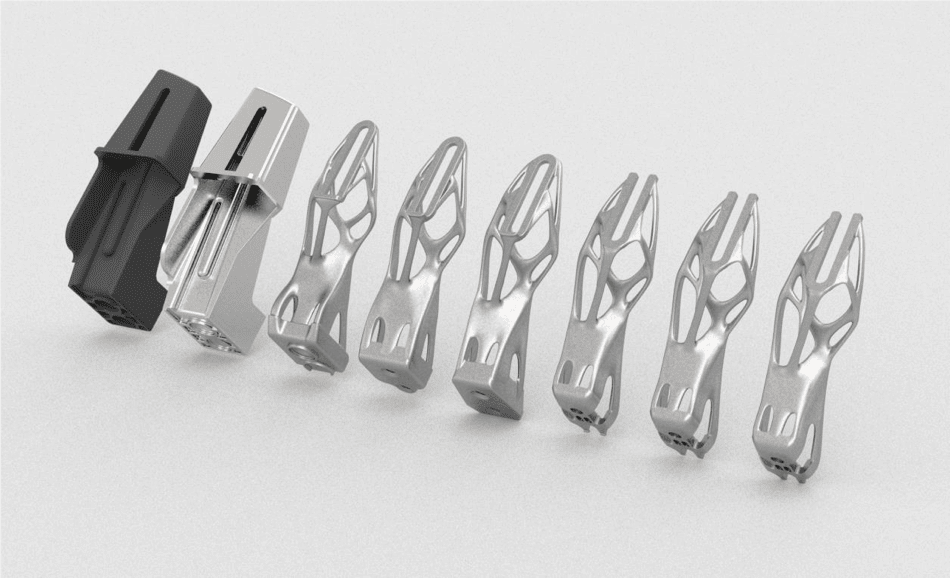

Topology optimization is a computational design method that determines the most efficient material layout within a given design space, subject to load conditions and performance requirements. In the context of 3D printing, it allows engineers to create geometries that would be impossible, or prohibitively expensive, to manufacture using traditional subtractive methods.

At its core, topology optimization integrates finite element analysis (FEA) with iterative algorithms. The process evaluates stress distribution, stiffness, and displacement across a part, then removes material from low-stress regions while reinforcing high-stress zones. The result is a structure that achieves maximum performance with minimum material usage.

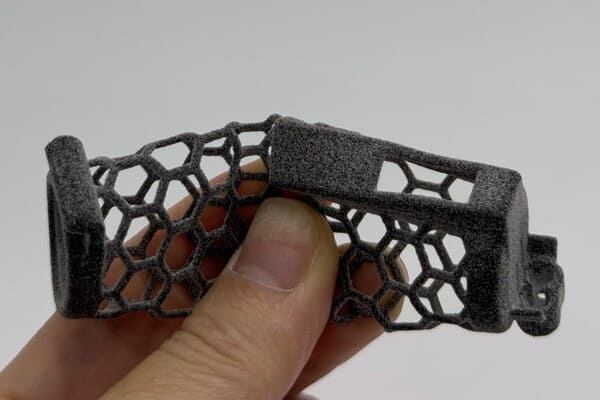

For additive manufacturing, this approach is transformative. Unlike machining or casting, 3D printing imposes fewer geometric constraints, enabling the production of organic, lattice-like, or biomimetic structures. These designs not only reduce weight but also enhance mechanical properties by aligning material placement with actual load paths.

From aerospace brackets to orthopedic implants, topology optimization has become a cornerstone of design for additive manufacturing (DfAM), bridging the gap between theoretical efficiency and practical manufacturability.

Image Source: Altair Enlighten

Mechanical Properties at Stake: Strength, Stiffness, and Fatigue

The mechanical performance of a 3D printed part is not solely determined by the material used. Instead, geometry and topology play equally critical roles. Three properties stand out:

Strength

Topology-optimized designs distribute loads more evenly, reducing stress concentrations that often lead to premature failure. For example, a bracket designed with topology optimization may achieve the same load-bearing capacity as a solid block while using 40% less material. This efficiency is particularly valuable in aerospace and automotive applications, where every gram matters.

Stiffness

Stiffness-to-weight ratio is a key metric in structural engineering. By aligning material along principal stress directions, topology optimization enhances stiffness without unnecessary mass. Lattice structures, for instance, can be tuned to achieve high rigidity while maintaining low density.

Fatigue Resistance

Fatigue is a critical concern in cyclic loading environments. Traditional designs often fail at stress risers, such as sharp corners or holes. Topology-optimized geometries minimize these weak points by creating smooth load paths and distributing stresses more uniformly. In medical implants, this translates to longer-lasting components that better mimic the mechanical behavior of natural bone.

Design Variables in 3D Printing: Orientation, Lattices, and Supports

While topology optimization provides the blueprint, the final mechanical properties of a 3D printed part are also influenced by process-specific design variables.

Print Orientation

3D printing is inherently anisotropic: properties vary depending on the build direction. A part printed vertically may exhibit lower tensile strength along the Z-axis due to weaker interlayer bonding. Engineers must therefore consider orientation as part of the optimization process, balancing mechanical performance with print time and support requirements.

Lattice and Infill Structures

One of the unique advantages of additive manufacturing is the ability to create internal lattice structures. These can be tailored to achieve specific stiffness, energy absorption, or thermal conductivity targets. For example, gyroid lattices provide isotropic mechanical behavior, while strut-based lattices can be tuned for directional stiffness.

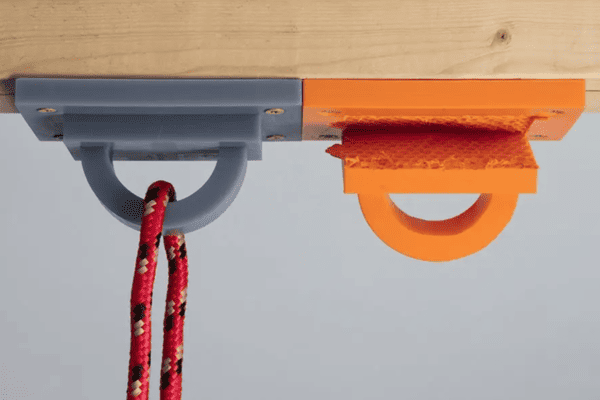

Support Structures

Supports are often viewed as a necessary inconvenience, but they also influence final part quality. Poorly designed supports can introduce residual stresses, distortions, or surface defects. Advanced optimization workflows now integrate support minimization into the design phase, ensuring that mechanical properties are not compromised by post-processing challenges.

Topological Case Studies in Aerospace, Automotive & Medical Industry

Aerospace: Lightweight Brackets and Fuel Efficiency

Airbus and NASA have both demonstrated the power of topology optimization in reducing aircraft weight. A topology-optimized titanium bracket, produced via selective laser melting (SLM), achieved a 30–40% weight reduction while maintaining equivalent load capacity. Such savings translate directly into lower fuel consumption and reduced emissions.

Automotive: Crash-Resistant Yet Lightweight Components

In the automotive sector, topology optimization has been applied to suspension components and structural reinforcements. By redistributing material only where needed, manufacturers have achieved parts that are both lighter and more crash-resistant. This dual benefit improves fuel efficiency while enhancing passenger safety.

Medical: Customized Implants with Bone-Mimicking Lattices

Perhaps the most human-centered application lies in medical implants. Topology optimization allows for implants that not only fit patient-specific anatomies but also replicate the mechanical behavior of bone. Porous lattice structures encourage osseointegration, while optimized load paths reduce stress shielding. The result is longer-lasting, more biocompatible implants.

Design for Better Performance

Integrating AI and Generative Design

Artificial intelligence is increasingly being used to accelerate topology optimization. Generative design tools can explore thousands of design permutations in hours, identifying solutions that balance strength, weight, cost, and manufacturability.

Multi-Material Printing

Emerging additive processes allow for the deposition of multiple materials within a single build, which opens the door to functionally graded structures, where stiffness, toughness, or thermal conductivity can vary across a part. Topology optimization will be essential in determining how to best distribute these materials.

Sustainability and Resource Efficiency

By minimizing material usage without sacrificing performance, topology optimization contributes to more sustainable manufacturing. Reduced waste, lower energy consumption, and lighter products all align with global sustainability goals.

Practical Adoption

For engineers, the key takeaway is that topology optimization should not be viewed as an optional add-on but as a core design philosophy. By integrating it early in the design cycle, companies can unlock performance improvements that extend beyond individual parts to entire systems.