Understanding Interlocking Parts

Interlocking parts are components designed to connect or fit together in a way that prevents separation without deliberate force or motion. They rely on geometry, friction, or mechanical features to hold assemblies together.

Benefits of Interlocking Parts

• Ease of assembly: No need for glue, screws, or external fasteners.

• Reusability: Parts can be disassembled and reused.

• Functionality: Enables moving mechanisms like hinges or sliding rails.

• Customization: Modular systems allow users to mix and match components.

Applications

• Consumer products: Toys, puzzles, modular organizers.

• Engineering prototypes: Snap-fit housings, enclosures, and mechanical joints.

• Architecture and design: Scaled models with modular connections.

• Furniture and decor: Flat-pack designs that lock together without tools.

Image Copyright © 3DSPRO Limited. All rights reserved.

Key Design Considerations

1. Material Choice

• Thermoplastics (FDM): PLA (rigid), ABS (tough, flexible), PETG (balanced), TPU (elastic).

• Resins (SLA/DLP): High precision, smooth surfaces, but brittle unless using toughened resins.

• Powder polymers (SLS/MJF): Nylon (PA12, PA11) offers strength, flexibility, and durability.

• Metals (SLM/DMLS): Stainless steel, titanium, aluminum, extremely strong but require larger tolerances due to shrinkage and post-processing.

2. Printer Capabilities

• FDM: Resolution limited by nozzle size; tolerances ~0.2–0.5 mm.

• SLA/DLP: Very high resolution; tolerances ~0.1–0.2 mm.

• SLS/MJF: Good accuracy for functional parts; tolerances ~0.2–0.4 mm.

• Metal powder-bed fusion: Shrinkage and heat distortion require ~0.5–1 mm clearance.

3. Strength vs. Flexibility

• Plastics: Balance between rigidity and elasticity.

• Resins: Precise but brittle unless reinforced.

• Polymers (nylon): Excellent fatigue resistance for repeated interlocks.

• Metals: Strongest, but interlocks must account for machining or finishing.

4. Print Orientation

• FDM: Layer adhesion affects snap-fit strength.

• SLA: Orientation impacts support removal and surface finish.

• SLS/MJF: Orientation is less critical, but affects powder removal.

• Metal fusion: Orientation impacts residual stress and post-machining.

Designing for Tolerances

Typical Tolerance Ranges

|

Technology |

Clearance Range |

Notes |

|

FDM |

0.2–0.5 mm |

Depends on nozzle size and calibration |

|

SLA/DLP |

0.1–0.2 mm |

High precision, but resin brittleness matters |

|

SLS/MJF |

0.2–0.4 mm |

Nylon parts allow flexible fits |

|

Metal (SLM/DMLS) |

0.5–1 mm |

Accounts for shrinkage, heat distortion, and post-machining |

Strategies

• Test prints: Calibration pieces with varying clearances.

• Iterative design: Adjust based on results.

• Parametric CAD: Easily modify tolerances.

• Post-processing: Sanding, machining, or polishing to refine fits.

Types of Interlocking Mechanisms

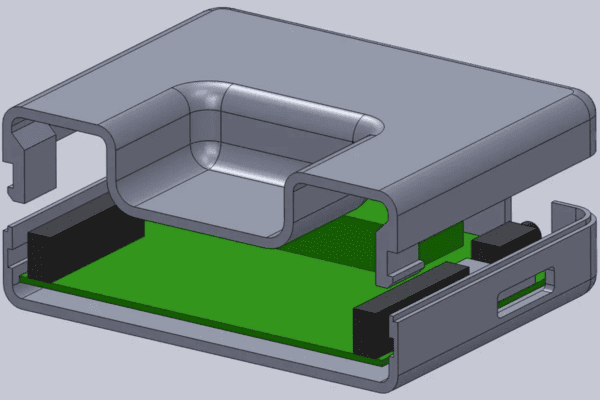

1. Snap-Fit Joints

• Plastics (FDM, SLS): Flexible arms or hooks.

• Resins (SLA): Possible but brittle—use reinforced geometries.

• Metals: Rare due to rigidity; better suited for sliding or bolted interlocks.

2. Rotational Locks

• Hinges: Common in plastics and resins.

• Twist-to-lock: Effective in polymers and metals with larger tolerances.

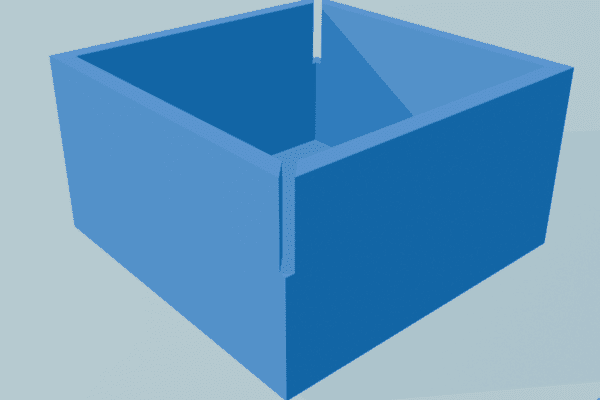

3. Sliding Interlocks

• Dovetail joints: Excellent for nylon (SLS/MJF) and metals.

• Rails and grooves: Work across all technologies, but require tolerance tuning.

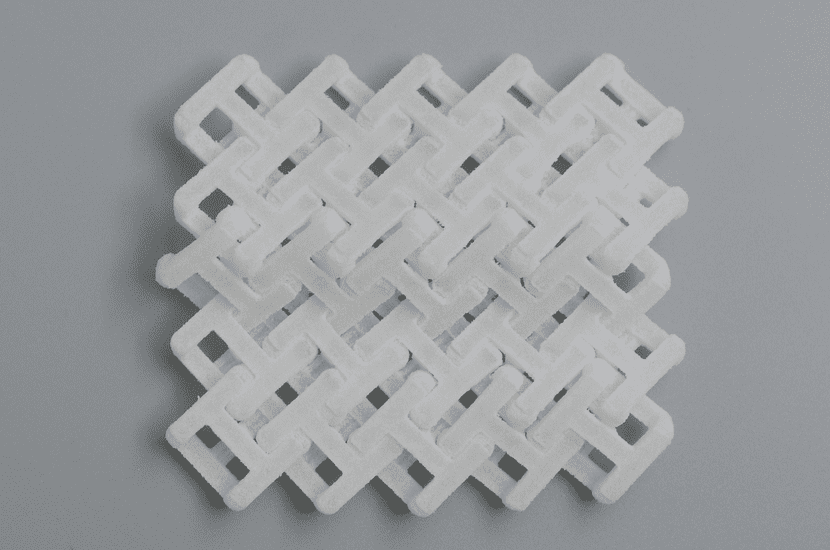

4. Puzzle-Style Connections

• Geometric interlocks: Best in high-precision SLA or nylon SLS.

• Decorative assemblies: Ideal for resin-based printing.

5. Hybrid Mechanisms

• Combining sliding with snap-fit for added security.

• Example: Nylon dovetail with a flexible latch.

CAD Design Best Practices

1. Use Parametric Modeling

• Allows easy adjustment of tolerances and dimensions.

• Facilitates iterative testing without rebuilding models.

2. Add Chamfers and Fillets

• Chamfers: Help guide parts into place.

• Fillets: Reduce stress concentrations and improve durability.

3. Consider Assembly Direction

• Design interlocks to assemble in one direction.

• Avoid requiring complex maneuvers that frustrate users.

4. Account for Print Orientation

• Align interlocking features with layer lines for strength.

• Minimize support material in critical areas.

5. Prototype Digitally

• Use CAD simulations to test the assembly before printing.

• Check for interference or impossible geometries.

6. Document Design Parameters

• Record tolerance values, material choices, and orientation.

• Helps future iterations and collaboration.

Common Mistakes to Avoid

1. Ignoring Printer Limitations

• Designing features smaller than the printer can resolve.

• Solution: Match design detail to printer resolution.

2. Forgetting Shrinkage and Warping

• Materials like ABS shrink after cooling.

• Solution: Adjust dimensions or use materials with low shrinkage.

3. Overcomplicating Interlocks

• Complex geometries may be unnecessary.

• Solution: Start simple—snap-fit or dovetail joints often suffice.

4. Neglecting Ergonomics

• Interlocks that require excessive force frustrate users.

• Solution: Design for ease of assembly and disassembly.

5. Skipping Test Prints

• Assuming tolerances will work without testing.

• Solution: Always print calibration pieces before final designs.

6. Poor Orientation Choices

• Printing interlocks in weak directions leads to breakage.

• Solution: Orient parts to maximize strength along stress lines.