Spray Painting Services at 3DSPRO

We offer 3D Printing Solutions and 3D Plus™ Solutions for customers. We can enhance, refine, and elevate your 3D printed creations to professional-grade finishes by our 3D Plus™ post-processing services.

3DSPRO has a team of experts who can handle any spray painting project, no matter the size, shape, or complexity of your 3D printed part. 3DSPRO can help you choose the right type of spray paint, color, and finish for your 3D printed part based on your design, requirements, and preferences.

If you are interested in 3D printing services and spray painting services with 3DSPRO, you can get a quote instantly and start your project. 3DSPRO is ready to help you accelerate your innovation with 3D printing.

3DSPRO Spray Painted Airplane

Common Types of Spray Paints

As we've discussed in the previous article, spray paint comes in a pressurized can and can be sprayed through a nozzle. Spray paint can give your 3D printed parts a smooth and professional finish, but you must choose the right spray paint for your project. There are many types of spray paints, and we are going to introduce some common types of spray paints and their features in the following section.

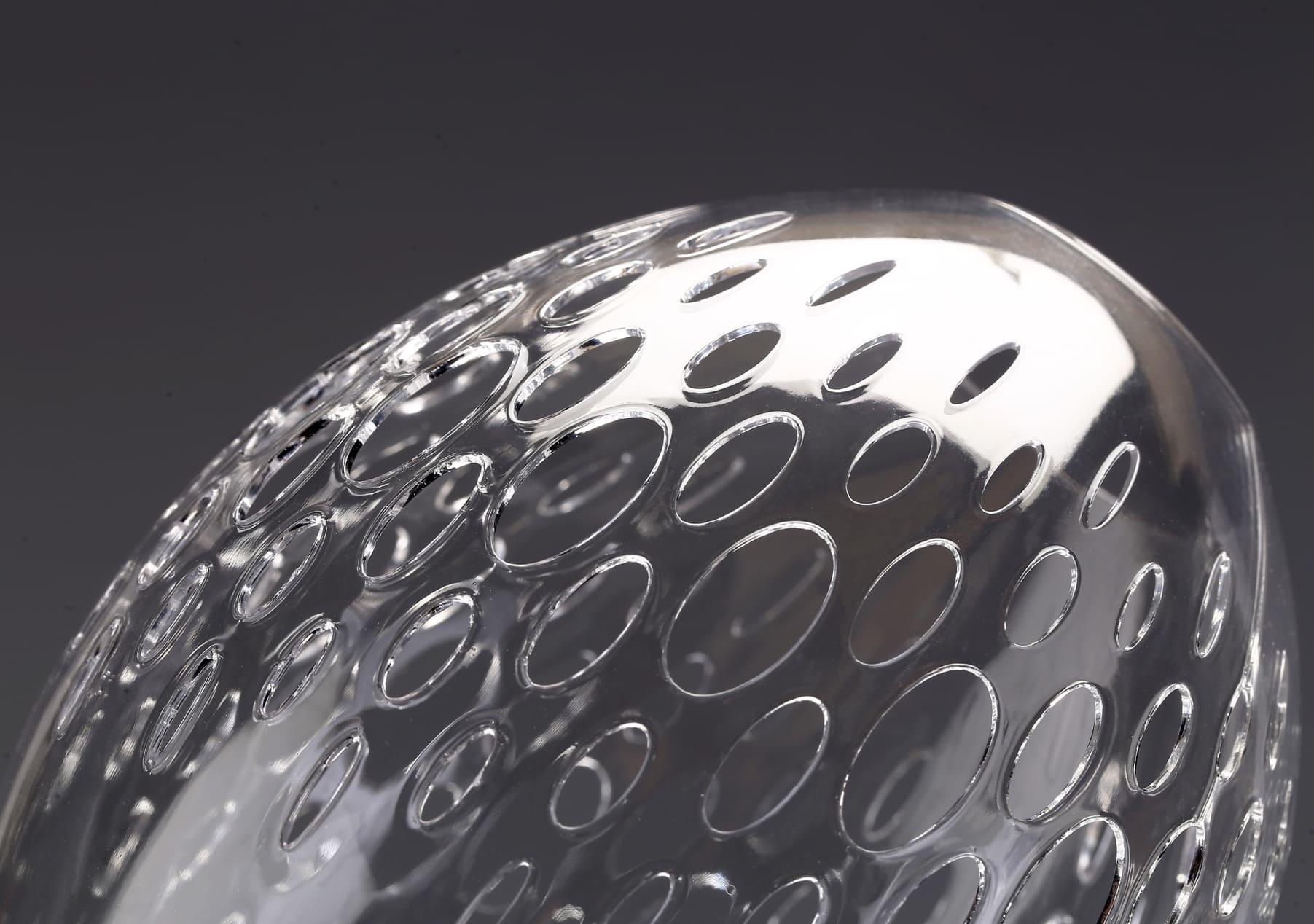

3DSPRO Spray Painted Samples

1. Oil-based Spray Paint

Oil-based spray paint is made from oil and resin, and it dries by evaporation. It is durable, water-resistant, and easy to apply. However, this paint has a strong odor, takes longer to dry, and requires a solvent for cleanup. Oil-based spray paint is suitable for metal, wood, and plastic surfaces.

2. High-heat Spray Paint

High-heat spray paint is specially formulated to withstand high temperatures, up to 1200°F. It is ideal for 3D printed parts exposed to heat, such as engine parts, grills, fire pits, and stoves. High-heat spray paint is resistant to cracking, peeling, and fading. However, thia paint requires a primer, has a limited color range, and may emit harmful fumes when heated. High-heat spray paint is suitable for metal surfaces.

3. Enamel Spray Paint

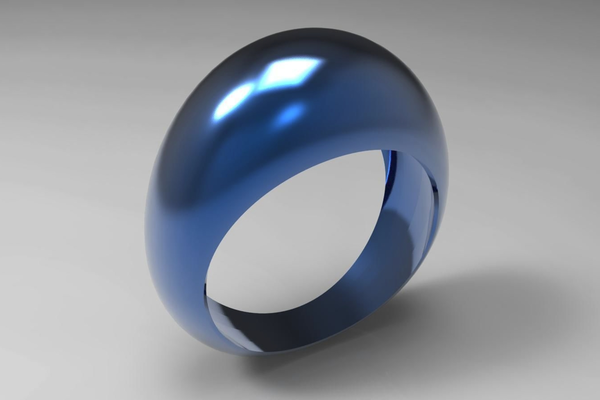

Enamel spray paint is made from synthetic resin and dries by oxidation. It is glossy, hard, and smooth. Enamel spray paint is ideal for 3D printed parts that need a shiny and polished look, such as jewelry, ornaments, and decorative items, which is easy to clean and maintain. However, this paint requires a primer, takes longer to dry, and may yellow over time. Enamel spray paint suits metal, wood, ceramic, and glass surfaces.

4. Lacquer Spray Paint

Lacquer spray paint is made from cellulose and dries by solvent evaporation. It is fast-drying, clear, and glossy. Lacquer spray paint is ideal for 3D printed parts that need a protective and transparent coating, such as models, sculptures, and artwork, which is easy to apply and reapply. However, it has a strong odor, is flammable, and may crack or chip over time. Lacquer spray paint is ideal for metal, wood, plastic, and paper surfaces.

5. Chalkboard Spray Paint

Chalkboard spray paint is made from latex and dries by water evaporation. It is matte, black, and writable. Chalkboard spray paint is ideal for 3D printed parts that need a fun and interactive surface, such as signs, labels, and boards. This paint is easy to erase and repaint. However, it requires a primer, multiple coats, and a curing time. Chalkboard spray paint suits metal, wood, plastic, and glass surfaces.

6. Acrylic Spray Paint

Acrylic spray paint is made from acrylic resin, and it dries by water evaporation. It is versatile, colorful, and durable. Acrylic spray paint is ideal for 3D printed parts that need a vibrant and creative look, such as toys, crafts, and graffiti. It is also easy to mix and blend. However, acrylic spray paint requires a primer, may fade or peel in sunlight, and may clog the nozzle. Acrylic spray paint is ideal for metal, wood, plastic, and fabric surfaces.

7. Epoxy Spray Paint

Epoxy spray paint is made from epoxy resin and dries by chemical reaction. It is strong, adhesive, and resistant. Epoxy spray paint is ideal for 3D printed parts that need a tough and protective finish, such as tools, appliances, and furniture. It is also easy to clean and waterproof. However, this paint requires a hardener, has a short pot life, and may emit toxic fumes. Epoxy spray paint is ideal for metal, wood, ceramic, and concrete surfaces.

8. Frosted Spray Paint

Frosted spray paint is made from acrylic resin, and it dries by water evaporation. It is translucent, textured, frosty, and easy to apply and remove. Frosted spray paint is ideal for 3D printed parts that need a decorative and elegant look, such as vases, lamps, and mirrors. However, this paint requires a clear coat, may scratch or smudge easily, and may not work well on dark surfaces. Frosted spray paint is suitable for glass and plastic surfaces.

9. Glow-in-the-dark Spray Paint

Glow-in-the-dark spray paint is made from phosphorescent pigment, and it dries by water evaporation. It is invisible, luminous, and fun. Glow-in-the-dark spray paint is ideal for 3D printed parts that need a spooky and magical look, such as costumes, props, and Halloween decorations. However, this paint requires a primer, multiple coats, and a dark environment. Glow-in-the-dark spray paint suits metal, wood, plastic, and fabric surfaces.

How to choose the right spray paint for your 3D printed part?

Spray paint is a convenient and versatile way to give your 3D printed part a smooth and appealing finish. However, not all spray paints are created equal, and choosing the wrong one can ruin your project.

Here are some tips to help you choose the right paint:

Compatibility

The first and most important factor is whether the spray paint is compatible with your 3D printing material. Certain spray paints may not adhere well, cause damage, or react with certain materials.

For example, oil-based spray paints may not be compatible with PLA because they may dissolve or soften the plastic. Lacquer spray paints, on the other hand, may melt ABS because they contain strong solvents that affect the chemical structure of the plastic.

You should always read the label of the spray paint and test it on a small area before applying it to the entire part. It will help if you also look for a spray paint designed for 3D printing, such as Rust-Oleum Painter's Touch 2X Ultra Cover, Krylon Fusion for Plastic, or Montana Gold. These spray paints are formulated to work with a variety of 3D printing materials, such as PLA, ABS, PETG, Nylon, and more.

Color

You can match the color of your 3D printed part with your design or create a contrast or a gradient effect. It would be best if you also thought about the opacity and coverage of the spray paint, as some colors may require more coats than others to achieve the desired result.

For example, light colors may need more coats to cover dark 3D printed models, while metallic colors may need more coats to create a shiny effect.

Mix and blend different spray paint colors to create custom shades and effects. For example, you can use a base coat of one color and a top coat of another color to create a two-tone or a color-shifting effect. You can also use masking tape, stencils, or decals to create patterns or designs on your 3D-printed part.

Finish

The finish refers to the texture and glossiness of the spray paint, which can affect the appearance and feel of your 3D printed part. Many types of finishes include matte, gloss, metallic, leather, rubber, and more. Choose the finish that suits your purpose and preference, and consider its durability and resistance.

For example, matte finishes may hide imperfections better, but gloss finishes may be more resistant to scratches and stains.

It would help if you also considered the finish's effect on the spray paint's color, as some finishes may alter the hue or brightness of the color. For example, metallic finishes may make the color more reflective, while frosted finishes may make the color more muted. You can also use clear coats or varnishes to seal and protect your spray paint finish and to create different effects, such as glossy, satin, or matte.

Preparation Before Spray Painting

Before spray painting your 3D printed part, you must prepare the surface and work area properly, which will ensure the spray paint will adhere well, cover evenly, and last longer.

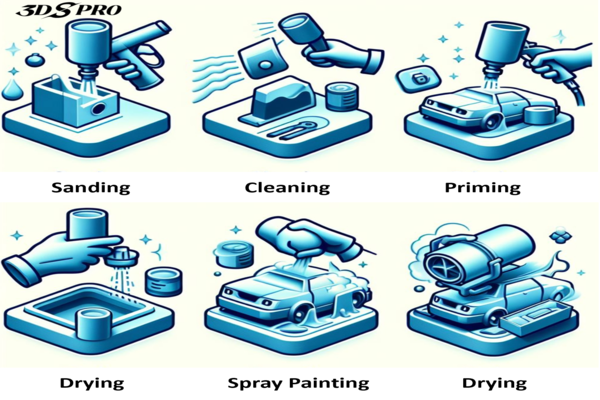

Here are some steps to follow for preparation before spray painting:

● Clean the surface of your 3D printed part. Remove any dust, dirt, grease, or residue from the surface, as those imperfections can prevent the spray paint from sticking or causing unevenness. You can use a soft cloth, a brush, a vacuum, or compressed air to clean the surface. You can also use mild soap and water, alcohol, or acetone to wipe the surface, depending on the type of 3D printing material.

● Sand the surface of your 3D printed part. Smooth and level the surface, as it may have bumps, ridges, or layer lines that can affect the quality of the spray paint. You can use sandpaper or a rotary tool with different grits, from coarse to fine. You must wear gloves, safety glasses, and a mask to protect yourself from dust and debris.

● Prime the surface of your 3D printed part. Apply a thin layer of primer to the surface, as it can help the spray paint adhere better and cover any imperfections. You must choose a primer compatible with your 3D printing material and spray paint. You need to spray the primer in a well-ventilated area, with multiple thin coats applied at a suitable distance and angle and with enough drying time between each coat.

● Mask the areas of your 3D printed part you don't want to paint. It would help if you covered the areas where you want to keep the original color or texture, such as holes, threads, or logos. You can mask the areas with painter's tape, paper, or plastic. It would help if you ensured the edges were sealed well to prevent the spray paint from leaking underneath.

● Prepare your work area. Working in a well-ventilated area would be best, as the spray paint can emit harmful fumes. You must also protect the surrounding area from overspray, as the spray paint can stain or damage other items. You can use newspaper, drop cloth, or a tarp to cover the ground and other surfaces. You can also use weights (like rocks) to keep the cover from blowing around in the wind.

Sanding:

Cleaning:

Painting:

COMMENTS

- Be the first to share your thoughts!