Bridging Heritage and Hyper-Innovation

The Air Max 1000 stands on the shoulders of giants. It reinterprets Tinker Hatfield’s revolutionary 1987 Air Max 1, keeping its soul—the visible Air unit—while shedding conventional construction. At ComplexCon 2024, Nike framed this launch as a cultural reset, displaying Frank Rudy’s early Air prototypes alongside Hatfield’s sketches. This wasn’t just a product drop; it was a narrative linking Nike’s past to its tech-driven future.

John Hoke, Nike’s Chief Innovation Officer, crystallized the vision: “It’s control, times precision, times expression—all vital to sport and design. Multiply those, and our future feels unlimited.” The AM 1000 answers decades of evolution with one seismic leap.

Image Source: Nike

Deconstructing the Design

Design Evolution – Air Max 1 vs. Air Max 1000

|

Element |

Air Max 1 (1987) |

Air Max 1000 (2025) |

|

Upper |

Layered mesh/suede panels |

Seamless 3D-printed lattice |

|

Construction |

Stitched assembly |

Single-piece printing |

|

Air Unit |

Encapsulated in midsole |

Transparent heel chamber |

|

Branding |

Prominent Swoosh |

Subtle debossing/block lettering |

Sculptural, Seamless, Sustainable

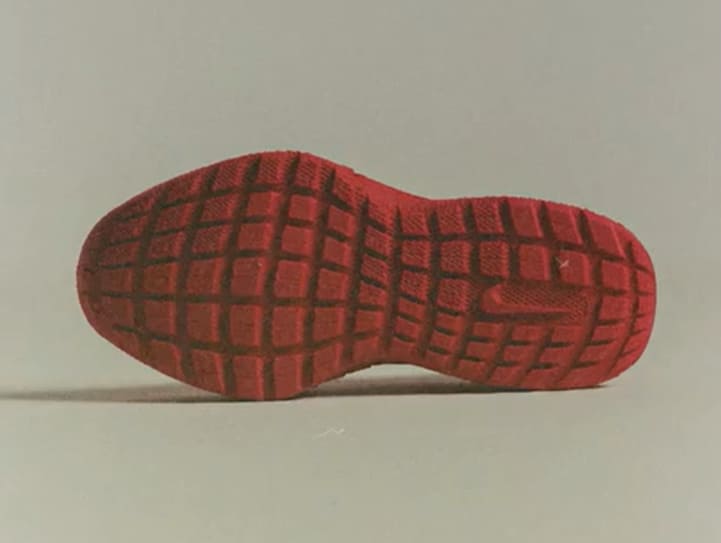

Gone are laces, stitches, and layered panels. The Air Max 1000’s upper and sole emerge as a single piece via Zellerfeld’s fused filament fabrication (FFF) process. Using thermoplastic polyurethane (TPU), the printer varies densities: firm underfoot for support, flexible above for adaptive comfort.

Anatomy of Innovation – Air Max 1000 Design Features

|

Element |

Technology |

Functional Benefit |

|

Upper |

Monolithic 3D-printed lattice |

Laceless slip-on; breathable fit |

|

Material |

ZellerFoam TPU (variable density) |

Lightweight yet durable |

|

Air Unit |

Non-printed "Total Orange" heel chamber |

Responsive cushioning |

|

Aesthetic Details |

Debossed Swoosh, "Air" heel lettering |

Minimalist branding |

The "Foamy Oat" colorway—neutral oatmeal with fiery orange Air—showcases the lattice texture while whispering Nike’s legacy. It’s tech as art.

Image Source: Nike

Manufacturing Revolution

Waste Not, Customize More

Traditional shoemaking involves cutting patterns from rolls of material, leaving up to 30% as scrap. Zellerfeld’s additive process prints only what’s needed, slashing waste dramatically. Each pair is "Made in Germany," emphasizing precision over mass production.

But the bigger story is customization. Cristian Gonzalez, Nike’s lead designer, notes the tech enables “engaging underfoot experiences” tailored to individual biomechanics. Soon, smartphones could scan your foot, and printers could mold your perfect fit—on demand.

Image Source: Nike

Implications for the Footwear Industry

1. Sustainable Scalability: Brands like Adidas and Gucci are already testing 3D-printed lines (e.g., Climacool24). Hybrid models, like Elastium’s collaboration with LaLaLand, blend printing with traditional methods to cut costs by 80%.

2. Luxury Meets Locality: Zellerfeld already prints for Louis Vuitton and Heron Preston. Micro-factories could replace offshore production, reducing shipping emissions.

3. Consumer Connection: Despite the excitement, skepticism lingers. The $210 price point draws debate, and Nike’s silence post-ComplexCon fueled doubts. Transparency in sustainability storytelling will be key.

3D Printing Shoes at 3DSRPO

While Zellerfeld’s FFF process birthed the Air Max 1000, other technologies like Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF) also utilize TPU to build shoes layer by layer. These methods enable:

Complex Geometries: Lattice structures for breathability unachievable via molding.

Rapid Prototyping: Accelerating design cycles from months to days.

On-Demand Production: No warehouses, no deadstock—print as ordered

Try 3DSPRO's SLS and MJF 3D Printing Services Here >>

COMMENTS

- Be the first to share your thoughts!