The Concept AMG GT XX represents a bold leap forward for Mercedes‑AMG into the electric-performance era. Boasting over 1,360 hp from three cutting-edge axial‑flux electric motors and a record-shattering charging capability of 400 km in just 5 minutes, the squarely positions AMG at the high-tech vanguard of supercars. Yet, amid its blistering power and aerodynamic mastery, it’s the interior that steals the spotlight—especially the 3D printed seat pads, a fusion of bespoke comfort and motorsport-grade engineering. Built around individually scanned driver profiles, these pads offer extreme ergonomic customization, rapid swap-out functionality, and cutting-edge sustainable materials.

CONCEPT AMG GT XX

Mercedes‑AMG has pulled off a bold pivot into electric performance with the Concept AMG GT XX, a four-door electric powerhouse delivering approximately 1,360 hp via three axial-flux motors and racing-inspired hardware. With a drag coefficient of just 0.198, intelligent aerodynamics, and hyper-fast charging (400 km of range in 5 minutes), this concept redefines what an AMG performance car can be.

Inside, its minimalist cockpit blends motorsport DNA with luxury. Expect carbon-fiber bucket seats, dual widescreen displays tilted toward the driver, and bold biotech materials like LABFIBER, all wrapped in aggressive orange accents. But the true game-changer? The custom 3D printed seat pads are tailored to individual drivers.

Image Source: Mercedes-AMG

The AMG GT XX’s 3D Printed Seat Pads

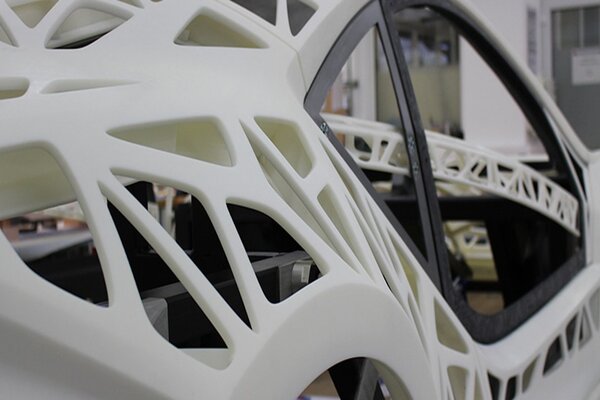

Forget traditional foam cushions. The AMG GT XX's seat pads are intricate, digitally crafted marvels produced using state-of-the-art 3D printing technology (specifically, Selective Laser Sintering - SLS). Instead of a uniform block of material, these pads feature a complex, multi-zone lattice structure. Imagine a lightweight, incredibly strong honeycomb or web-like pattern but far more sophisticated:

• Digital Design Precision: Every curve, every support point, and every breathable zone is meticulously designed in 3D software before a single layer is printed.

• Lattice Structure: This internal architecture is the key. It allows for precise tuning of properties like firmness, flexibility, and damping characteristics within different areas of the same pad.

• Multi-Zone Performance: Zones requiring maximum support (like under the thighs and around the pelvis) can have a denser, firmer lattice. Areas needing pressure relief or ventilation (like the central back or base) feature a more open, flexible structure.

•Seamless Integration: These printed pads are designed to fit perfectly within the seat's overall structure and upholstery, providing the core comfort and support layer.

Image Source: Mercedes-AMG

How 3D Printing Enables “Ergonomics on Demand”

This is where "Ergonomics on Demand" truly happens by 3D printing:

Body Mapping: Using advanced scanning technology, AMG can capture the precise contours, weight distribution, and pressure points of an individual driver's body.

Digital Tailoring: This unique biometric data is fed into the design software. The lattice structure of the seat pad is then algorithmically generated and optimized specifically for that individual. Need firmer lumbar support? More cushioning for your specific sit bones? It's programmed in.

On-Demand Production: Once the perfect digital design exists for Driver X, the 3D printed seat pads are manufactured to that exact specification. No expensive molds, no minimum order quantities – just direct digital-to-physical creation.

Perfect Fit: The result is a seat pad that feels like it was grown for the driver. Pressure is distributed evenly, reducing fatigue. Support is precisely where it's needed, enhancing control and feedback. Comfort is maximized, even during long stints or aggressive driving.

Materials and Sustainability

Materials matter almost as much as form. The seat pads themselves are covered in LABFIBER, a biotech leather reinforced with recycled AMG GT3 racing tires and biopolymers. Made via Modern Meadow’s “Innovera” process, this sustainable alternative offers many benefits:

Over 80% from renewable sources, plant proteins + recycled rubber.

Breathable, waterproof, and stronger than traditional leather.

High-end finish that mimics Nappa leather without animal materials

By pairing 3D printed seat pads with biodegradable biotech fabrics, AMG is using 3D printing in automotive to reduce environmental impact while enhancing luxury and durability.

Image Source: Mercedes-AMG

Performance & Comfort Benefits

1. Enhanced Driver Performance: Superior support and pressure distribution significantly reduce physical fatigue, allowing drivers to maintain focus and precision for longer periods, whether on track or a demanding road. The tailored fit improves the "feel" of the car's dynamics.

2. Unparalleled Comfort: Elimination of pressure points and hotspots prevents numbness and discomfort. The lattice structure also promotes airflow, reducing heat and moisture buildup – goodbye, sweaty backs!

3. Optimal Body Positioning: Precise support helps maintain the ideal driving posture, which is crucial for control and reaction times, especially during high-G cornering or braking.

4. Weight Reduction: 3D printed lattice structures are significantly lighter than traditional dense foam blocks, contributing to the AMG GT XX's overall performance ethos.

5. Durability: The high-performance materials resist sagging and degradation far better than conventional foams, ensuring the perfect fit lasts.

3D Printing x Automotive in the Future

Looking ahead, the AMG GT XX’s use of 3D‑printed seat pads represents just the beginning of a broader trend where 3D printing in automotive enables truly personalized and sustainable production—imagine mass-customized interiors where every panel and cushion is tailor-made to driver preferences, all produced on-demand without traditional tooling, cutting waste and cost while accelerating time-to-market. Major automakers, from Porsche (with 3D printed lattice-seat prototypes) to Volkswagen and Ford, are already leveraging additive manufacturing for lightweight, complex components and bespoke interior pieces. As materials and printer speed continue to evolve, expect AMG’s innovation to scale beyond limited editions—soon, every interior surface, from door trims to headrests, could be individually configured, printed, and swapped, marking a future where performance, comfort, and sustainability are fused through digital manufacturing.

Image Source: Mercedes-AMG

COMMENTS

- Be the first to share your thoughts!