Printed vs CNC vs Metal Tooling

|

Criteria |

3D Printed Tooling |

CNC (Polymer or Metal) |

Metal Tooling |

|

Lead time |

Very fast (days) |

Moderate (days–weeks) |

Slow (weeks–months) |

|

Cost (Low Volumes) |

Low upfront cost |

Moderate |

High upfront cost |

|

Complexity / Internal Geometry |

Excellent (no extra cost) |

Moderate (harder, expensive) |

Limited or costly |

|

Dimensional Accuracy & Tolerance |

Good (process dependent) |

Very good |

Excellent |

|

Durability / Cycles |

Moderate (process & material dependent) |

Good |

Excellent (high cycles) |

|

Best for |

Jigs, fixtures, assembly aids, low-run molds |

Precision fixtures, hardened faces |

High-volume tooling, high pressure/temperature molds |

Rule of thumb

Use 3D printing for quick-turn fixtures, complex or one-off jigs, and low-volume molds where part counts are low-to-moderate and extreme wear or heat isn’t dominant. Choose CNC or metal if you need tight tolerances, long tool life, or high thermal and mechanical loads.

3D Printing Technologies for Tooling

SLA (Stereolithography)

• Strengths: Very high surface finish and fine detail; excellent for molds with smooth cavities or jigs that need precise locating surfaces.

• Limits: Many standard SLA resins are brittle and have limited heat and wear resistance; high-temp resins exist for tooling but cost more. Good for master patterns, low-run molds (silicone casting), and precision jigs.

SLS (Selective Laser Sintering)

• Strengths: Tough, fatigue-resistant, and good for functional fixtures and jigs. No need for support structures simplifies nested or complex geometry.

• Limits: Surface finish is grainy; dimensional variation vs. machining. Good for durable fixtures, templates, and some mold cores.

MJF (Multi Jet Fusion)

• Strengths: Similar materials to SLS but often with better dimensional stability and finer feature reproduction; fast throughput for multiple identical fixtures.

• Limits: Still polymer-based; heat and abrasion resistance limited compared with metals. Excellent for robust fixtures and jigs that require moderate precision.

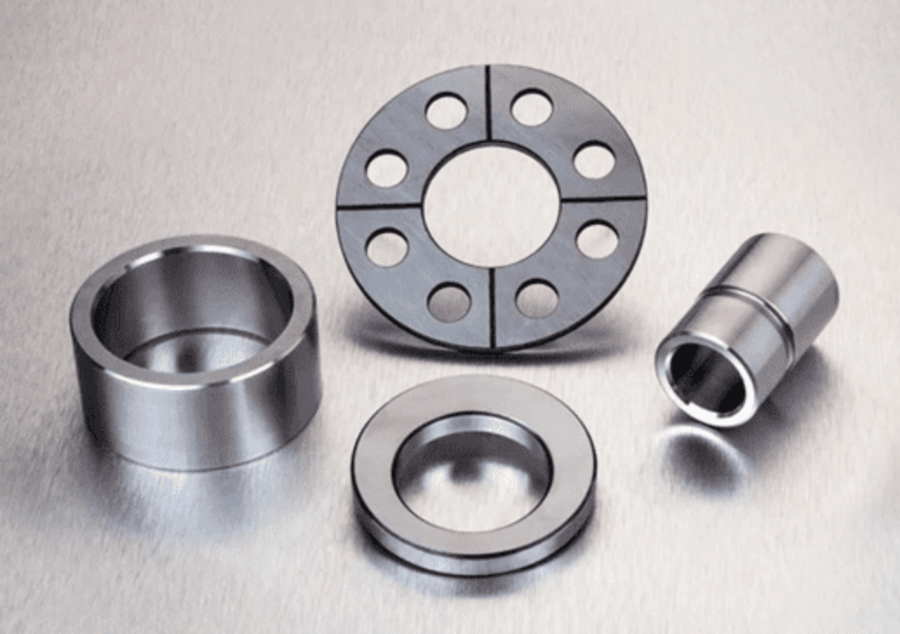

SLM (Selective Laser Melting)

• Strengths: Real metal properties, excellent strength, wear resistance, and temperature tolerance. Ideal for hardened tooling faces, inserts, or full metal jigs.

• Limits: Cost and lead time higher than polymer printing; post-processing (stress relief, machining) often required. Use when polymer tooling won’t survive the operating environment.

Materials: Properties and Selection

Choosing the right material is critical. Key properties to match to application: tensile strength, flexural modulus, heat deflection temperature (HDT), wear resistance, and chemical resistance.

Common Choices

1. Nylon (SLS/MJF): tough, good fatigue resistance, reasonably heat resistant. Good for most fixtures and jigs.

2. High-temp SLA resins: smooth surfaces and higher HDT; useful for molds and precision locating features, but can be brittle.

3. Reinforced Nylon or Carbon-filled polymers: stiffer, better dimensional stability for fixtures that need rigidity.

4. Polycarbonate-like materials (when available): higher toughness and impact resistance for heavy-handling jigs.

5. Stainless steel / tool steels (SLM): for wear surfaces, hot molds, or when metal properties are required.

Selection Checklist

1. Match HDT to the operating temperature (including post-processing or sterilization).

2. If parts see sliding contact, choose materials with good abrasion resistance or plan for wear coatings/inserts.

3. For threaded or repeated fastener usage, integrate metal inserts or pick a material compatible with heat-set inserts.

Design Guidelines for Jigs and Fixtures

Designing for printed tooling focuses on repeatability, structural integrity, and ease of maintenance.

Key Rules

1. Define datums and locating features clearly. Make sure datum surfaces are large enough to repeatably locate parts; consider machined or plated faces for critical datums.

2. Use ribs and gussets rather than solid mass to add stiffness, printed parts can be lightweight yet stiff.

3. Design for print orientation. Orient critical surfaces to minimize layer lines and shrinkage effects; address anisotropy by aligning load directions with stronger axes when possible.

4. Embed metal inserts or fasteners for high-wear threaded connections and load paths. Heat-set or press-fit inserts improve life dramatically.

5. Modularity: design fixtures so wear surfaces or high-stress modules can be replaced without reprinting entire tool.

6. Allow for tolerances and post-processing. Add material for machining on critical faces (machine stock) or plan for finishing operations. Use nominal dimensions appropriate for process capability.

7. Heat dissipation and vents: for molds or tools exposed to heat, include channels or provisions for cooling if needed.

Low-Volume Molds: Approaches and Limits

Direct Printed Molds

Best when part counts are low (often dozens to a few hundred), geometry is complex, and surface finish matters. Use high-temp SLA resins or engineered polymers. Expect limited cycle life compared with steel molds; monitor for heat and wear.

Printed Master for Silicone Casting

Print a master pattern, then create a silicone mold for casting urethanes or resins. It is inexpensive and ideal for small production runs (tens to low hundreds). Master surface finish and release preparation are critical.

Hybrid Molds

Combine printed cores and inserts with machined metal cavities to reduce cost while improving durability. Printed inserts may be replaced as they wear, extending overall mold life.

Expectations and Limits

Printed molds are excellent for short runs or design validation. Do not expect the tens of thousands of cycles typical of hardened steel molds unless parts are metal printed and post-processed accordingly. For thermoplastics that require high clamping force and temperature, steel molds are still the norm.

Post-processing, Finishing and Inserts

Post-processing converts a printed jigsaw into reliable shop tooling.

• Surface Finishing: sand, bead-blast, or vapor-smooth to reduce friction and improve mating surfaces. SLA provides the smoothest starting surface.

• Coatings and Plating: apply wear coatings, epoxy impregnation, or electroplating on polymer tools to extend life and improve wear resistance.

• Machining Critical Faces: add machine stock in the design and finish-machine bearing surfaces or datums for precise fits.

• Heat Treatment and Stress Relief (mainly for metals): required after SLM to stabilize dimensions and improve mechanical properties.

• Insert Installation: use heat-set or threaded metal inserts in areas with repetitive fastening; consider dowel pins or metal locators for high-precision registration.

• Inspection and Validation: perform first-article checks (CMM or gauge checks), run a pilot batch, and track wear across cycles to determine replacement intervals.

COMMENTS

- Be the first to share your thoughts!