What is anodizing?

Anodizing is an electrochemical process that increases the thickness of the natural oxide layer on the surface of metal parts, particularly aluminum. It’s a process that thickens and toughens the naturally occurring protective oxide, yielding a surface that is more durable, corrosion-resistant, and receptive to color dyes.

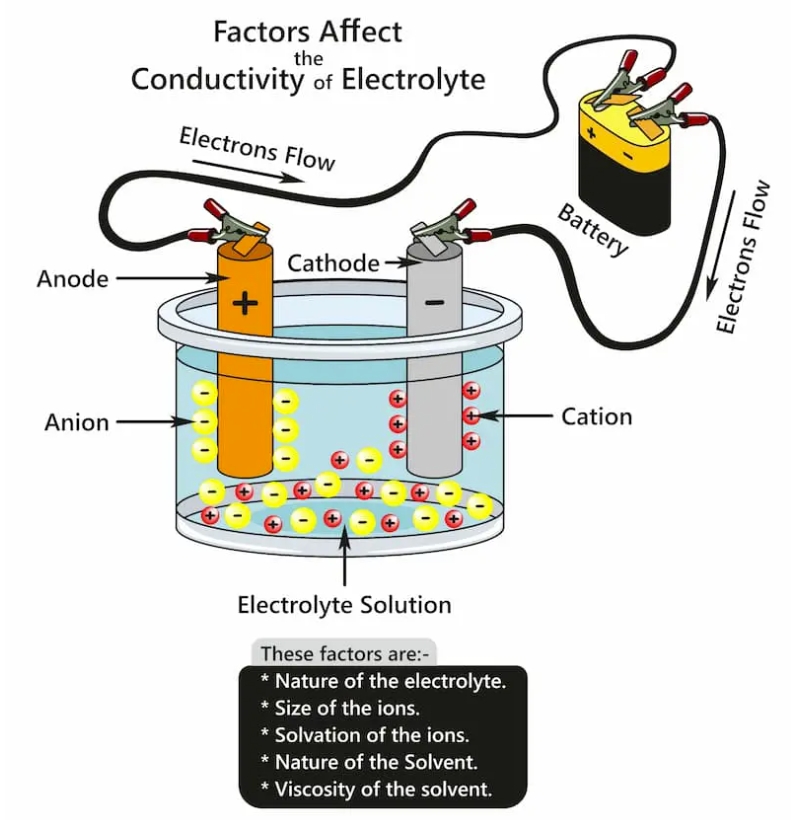

The magic of anodizing happens in an electrolytic cell, where aluminum acts as the anode. When submerged in an acid electrolyte bath and exposed to an electric current, the aluminum’s surface undergoes a controlled oxidation. This reaction causes the aluminum atoms to bond with oxygen ions, creating a layer of aluminum oxide.

From the aerospace industry to kitchen appliances, anodized aluminum is everywhere.

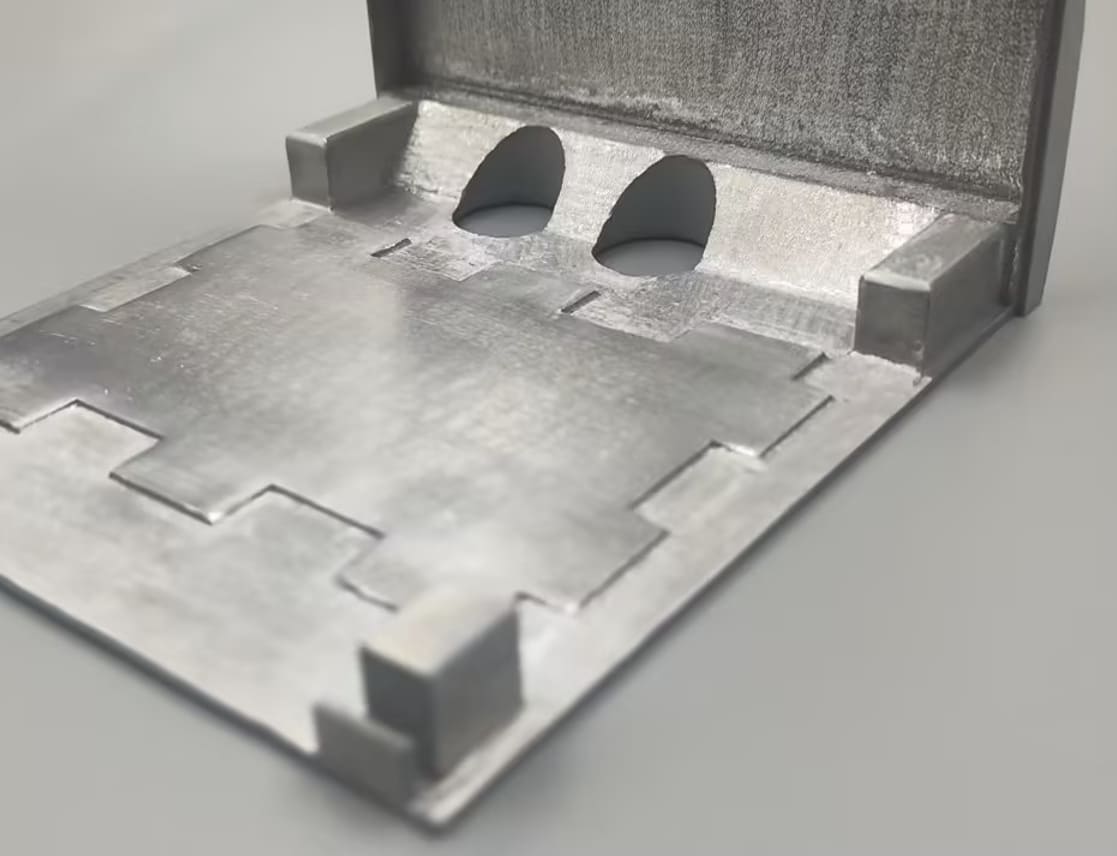

Image Source: AT PRECISION MACHINING

What is anodized aluminum?

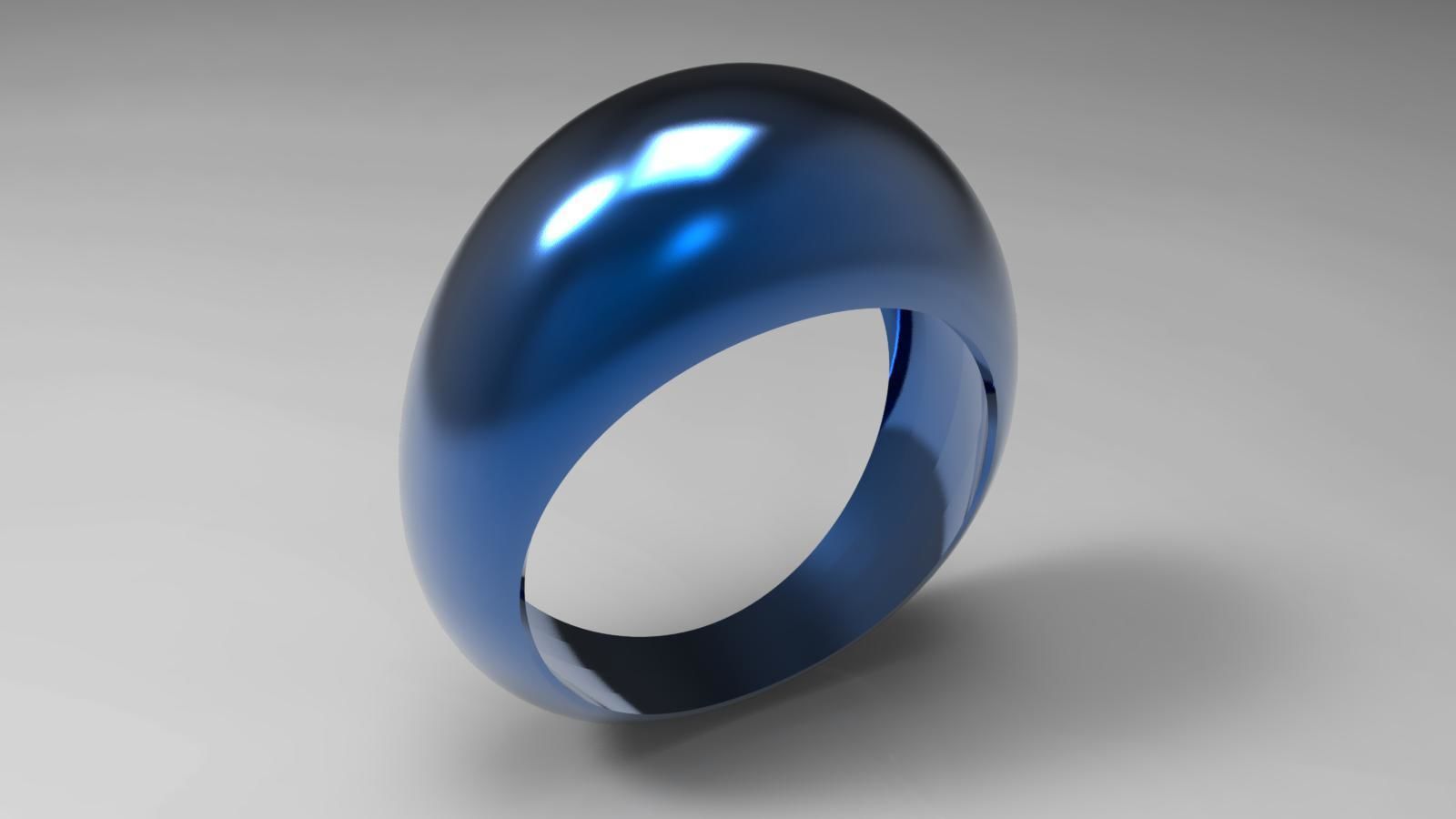

Anodized aluminum is a special type of aluminum that has undergone the anodizing process to create a durable and protective oxide layer on its surface. This layer is not applied like paint or a coating but is fully integrated with the underlying aluminum substrate.

Anodized aluminum is significantly harder than standard aluminum. It’s resistant to scratching and wear, making it ideal for applications that require durability. Anodizing can produce a variety of colors on aluminum without using dyes. The metal itself, through the anodizing process, can be colored in a range of hues that are vibrant and long-lasting. Besides, the anodic layer also acts as an insulator, making anodized aluminum a good choice for non-conductive applications.

Image Source: AMF Technologies

Can aluminum 3D prints be anodized?

The process of anodizing, which creates a hard, corrosion-resistant surface, is well-established for traditional aluminum parts. However, the process encounters some unique challenges for 3D printed aluminum parts.

3D printed aluminum typically contains a higher percentage of silicon (around 10%) in the alloy (AlSi10Mg), which can affect the anodizing process. Silicon is not as reactive as aluminum in the anodizing electrolyte, leading to a less uniform and potentially weaker anodic layer.

Despite the challenges, anodizing 3D printed aluminum is technically possible:

● Surface Preparation: Ensuring the 3D printed part is clean and free of any residues.

● Anodizing: Submerging the part in an acid electrolyte bath and passing an electric current through it to build up the oxide layer.

● Coloring (Optional): Applying dyes to the porous anodic layer if a colored finish is desired.

● Sealing: Closing the pores in the anodic layer to enhance durability and corrosion resistance.

Considerations for Anodizing 3D Printed Aluminum

● Surface Quality: The initial surface quality of a 3D printed part is crucial, as any imperfections will be magnified by the anodizing process.

● Alloy Composition: The specific alloy used for 3D printing can impact the anodizing results, with some alloys responding better than others.

● Post-Processing: Additional post-processing steps may be necessary to achieve a smooth surface before anodizing.

Image Source: CGTrader

How to anodize aluminum?

1. Cleaning: Begin by thoroughly cleaning the aluminum part to remove any contaminants that could interfere with the anodizing process.

2. Setup: Prepare an anodizing bath using a mixture of distilled water and an acid like sulfuric acid. The exact ratio can vary, but a common mixture is a 1:1 ratio of water to acid.

3. Electrolytic Bath: Submerge the aluminum part in the bath and connect it to the positive terminal of a power source. The negative terminal is connected to a cathode, which is also placed in the bath.

4. Anodizing: Run the power to the aluminum for a set amount of time, which can range from 30 minutes to an hour, depending on the desired thickness of the oxide layer.

5. Coloring (Optional): After anodizing, the part can be placed in a dye bath if a colored finish is desired. The porous oxide layer will absorb the dye.

6. Sealing: Finally, the part is sealed to close off the pores in the oxide layer and lock in the color if dyed, which is typically done by boiling the part in clean water or using a sealing solution.

Image Source: Fractory

Advantages of Anodized Aluminum

● Durability: The anodized layer is integrated with the metal, meaning it doesn’t peel or chip. It’s tough enough to withstand the challenges of harsh environments and frequent handling.

● Corrosion Resistance: Anodizing provides a barrier against rust, making aluminum suitable for outdoor applications and environments prone to corrosion.

● Aesthetic Flexibility: The porous nature of the anodized layer allows for the introduction of dyes, offering a spectrum of colors for designers and manufacturers.

● Improved Adhesion: Paints and adhesives bond better to anodized aluminum, ensuring finishes and labels remain intact over time.

● Eco-Friendly: Anodizing is a safe process that doesn’t produce harmful or toxic substances, aligning with green manufacturing initiatives.

What are the main differences between anodizing and electroplating?

Electroplating involves depositing a layer of metal ions onto a substrate using an electric current. The substrate becomes the cathode in an electrolytic cell, and the metal ions in the solution are attracted to it, forming a coating. This coating can improve the appearance, conductivity, and corrosion resistance of the substrate.

Anodizing is specific to creating a durable oxide layer on aluminum and titanium, whereas electroplating deposits a metallic layer onto a wide range of substrates for various functional and decorative purposes.

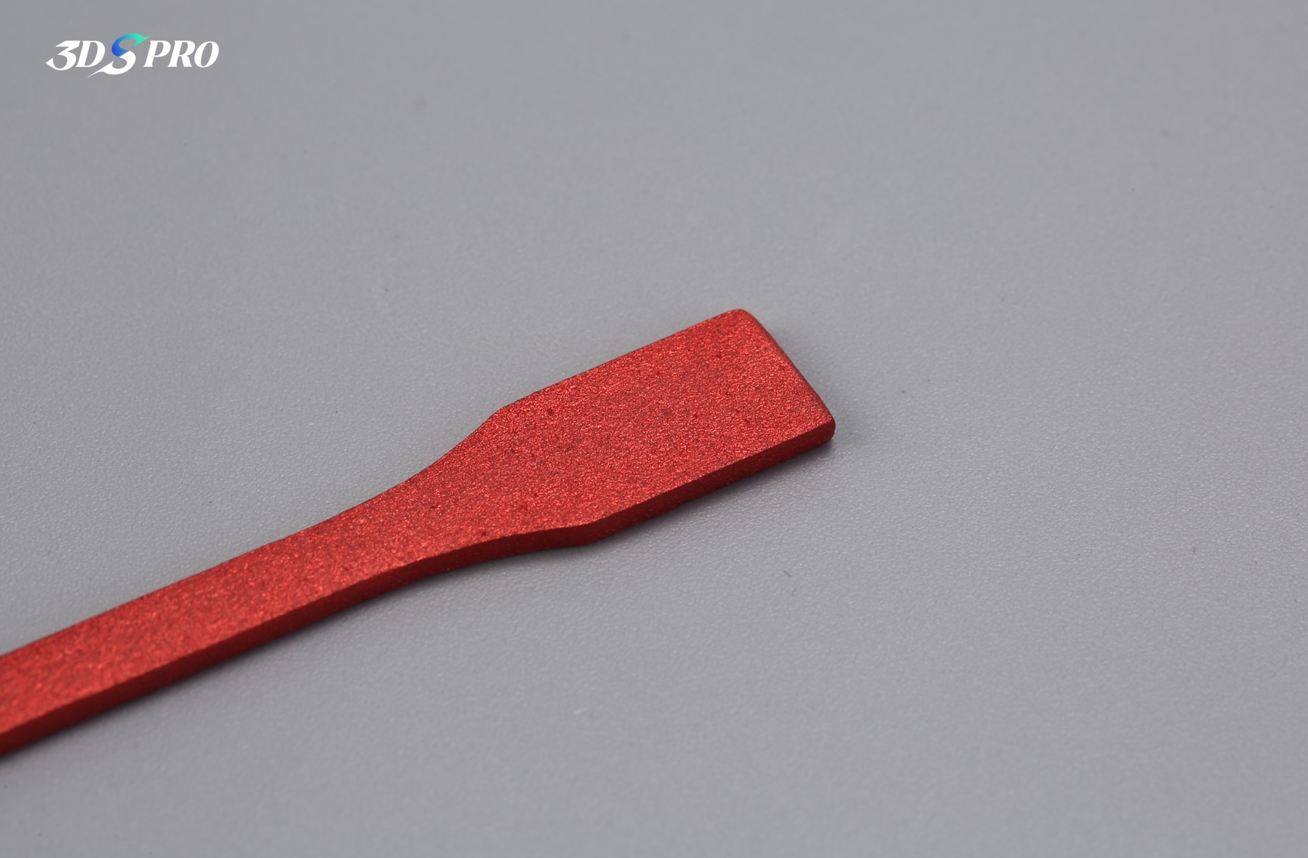

3DSPRO Electroplated Aluminum:

3DSPRO 3D Plus™ Solutions Offer Anodizing

3DSPRO 3D Plus™ Solutions are revolutionizing the way we think about 3D printing and post-processing. With a comprehensive approach to the 3D printing ecosystem, 3DSPRO offers anodizing services that elevate the quality and functionality of 3D printed metal parts.

Clients can choose from a range of colors and finishes to match their design specifications. 3DSPRO’s anodizing process allows for a high degree of customization, making it suitable for prototypes and end-use products.

Each anodized part undergoes a rigorous finishing check to ensure that the appearance and quality meet the client’s expectations.

COMMENTS

- Be the first to share your thoughts!