What is powder coating?

Powder coating is a dry finishing process that has gained popularity due to its efficiency and environmental benefits. Unlike traditional liquid paints, powder coating does not require a solvent to keep the binder and filler parts in a liquid suspension form. Instead, it is applied as a free-flowing, dry powder, typically using an electrostatic method, and then cured under heat or with ultraviolet light.

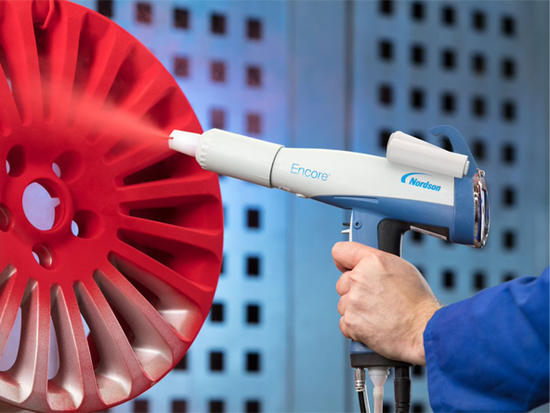

The powder used for coating is a mixture of finely ground particles of pigment and resin, which is sprayed onto a surface to be coated. The charged powder particles adhere to the electrically grounded surfaces until heated and fused into a smooth coating in a curing oven. The result is a uniform, durable, high-quality, and attractive finish that is tougher than conventional paint coatings.

Powder coating is mainly used for the coating of metals, such as household appliances, aluminum extrusions, and automobile and bicycle parts. However, recent advancements have allowed for its application on non-metallic substrates like plastics, composites, carbon fiber, and MDF (medium-density fibreboard).

Powder coating offers a thicker coating without running or sagging, minimal volatile organic compounds (VOCs) emissions, and the ability to create a wide range of specialty effects.

3DSPRO Powder Coating Service for 3D Printed Metal Part

Powder Coating Cost

The cost of powder coating can vary widely depending on several factors, including the size and complexity of the item, the type of material, the finish required, and the condition of the item before coating. On average, powder coating costs range from $75 to $300 per item.

For specific items like car wheels, the cost can be between $50 to $180 each, while larger items like a car frame may cost between $1,000 to $1,500.

Image Source: Nordson

Powder Coating Types

Thermoset Powder Coatings

These are the most commonly used types of powder coatings. When cured, they react chemically to form a permanent bond. This reaction makes them insoluble and infusible. Thermoset coatings are known for their durability and resistance to chemicals, heat, and corrosion. They are often used in appliances, automotive components, and outdoor furniture.

Thermoplastic Powder Coatings

Unlike thermoset, thermoplastic coatings do not undergo a chemical change when cured, which means they can be remelted and reshaped. They are known for their high-impact resistance and flexibility. Common applications include coatings for car bumpers, bicycle racks, and other items that require a durable yet flexible finish.

UV-Curable Powder Coatings

These coatings are cured using ultraviolet light rather than heat, making them suitable for heat-sensitive materials. UV-curable coatings are fast to cure and environmentally friendly due to low energy consumption and no emissions. They are applied to a variety of substrates, including plastics, composites, carbon fiber, and MDF (medium-density fibreboard).

Image Source: Custom Powder Solutions

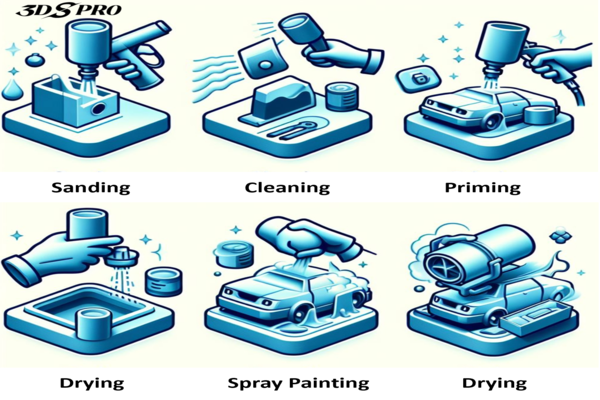

The Process of Powder Coating 3D Printed Parts

Surface Preparation

The 3D printed part is cleaned to remove any dust, grease, or residues. This step may involve washing with a solvent or a mild alkaline solution and is crucial for ensuring the powder coating adheres properly.

Pre-Treatment

Depending on the material of the 3D printed part, a pre-treatment such as a chemical etching might be necessary to create a surface conducive to powder adhesion.

Applying the Powder

The powder is electrostatically charged and sprayed onto the surface of the part. The electrostatic charge ensures that the powder sticks to the surface evenly before it’s cured.

Curing

Once the part is coated, it is placed in a curing oven where the powder is melted and cross-linked to form a uniform film. The curing process typically involves heating the part to temperatures between 160°C and 200°C for a specific duration, depending on the type of powder used.

Cooling

After curing, the part is cooled in a controlled manner to avoid any thermal shock or deformation of the 3D printed material.

Quality Check

The final step is to inspect the coated part for any defects or irregularities in the coating. A quality powder coating should be even, without drips or bubbles, and should fully cover the part’s surface.

Image Source: Moz Designs

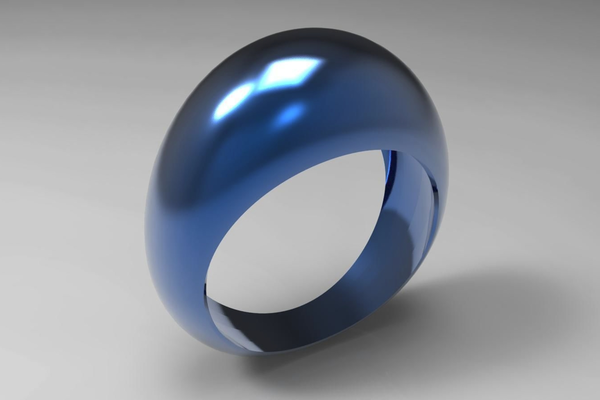

Powder Coating Colors

Powder coating technology allows for a diverse range of colors, from standard options to custom hues. You can choose from thousands of colors and shades, including but not limited to antique pink, anthracite gray, bottle green, chocolate brown, chrome, carmine red, and heather violet. Essentially, any color you can imagine is available in powder coating.

For projects requiring a specific color match, custom colors can be created, which is particularly useful for corporate branding or when trying to match other elements in a product line.

Image Source: PowderWerx

Powder Coating Applications

Automotive Industry

Powder coatings are extensively used in the automotive sector for components such as wheels, bumpers, door handles, radiators, shock absorbers, and engine parts. They provide a durable and attractive finish that can withstand harsh conditions.

Appliances

In the appliance industry, powder coatings are applied to front and side panels of ranges and refrigerators, washer tops and lids, dryer drums, air-conditioner cabinets, and dishwasher racks. They offer resistance to abrasion, chemicals, and temperature cycling.

Outdoor Furniture

Powder coatings are ideal for outdoor furniture due to their UV resistance and ability to withstand weather elements, maintaining their color and finish over time.

Building & Construction

The building and construction industry benefits from powder coatings for architectural metalwork, aluminum extrusions, and structural steel, providing long-lasting protection and aesthetics.

Electrical/Electronics

Powder coatings are used for exterior housings in electrical and electronic industries, offering protection while maintaining the functionality of the components.

Non-Metallic Products

With advancements in technology, powder coatings are now also applied to non-metallic substrates like plastics, composites, and MDF, expanding their use beyond traditional metal products.

Aerospace Industry

The aerospace industry utilizes powder coatings for parts that require a high level of precision and durability, such as certain interior components and exterior aircraft surfaces.

Agriculture Industry

Farming equipment and machinery benefit from powder coatings as they provide a tough finish that can resist the wear and tear of agricultural activities.

Industrial Machinery

Heavy-duty industrial machinery is often powder-coated to protect against corrosion, chemicals, and mechanical stress, ensuring longevity and reliability.

Consumer Goods

Many everyday items, from bicycles to lighting fixtures and sports equipment, are powder-coated for enhanced appearance and protection.

Image Source: IFS Coating

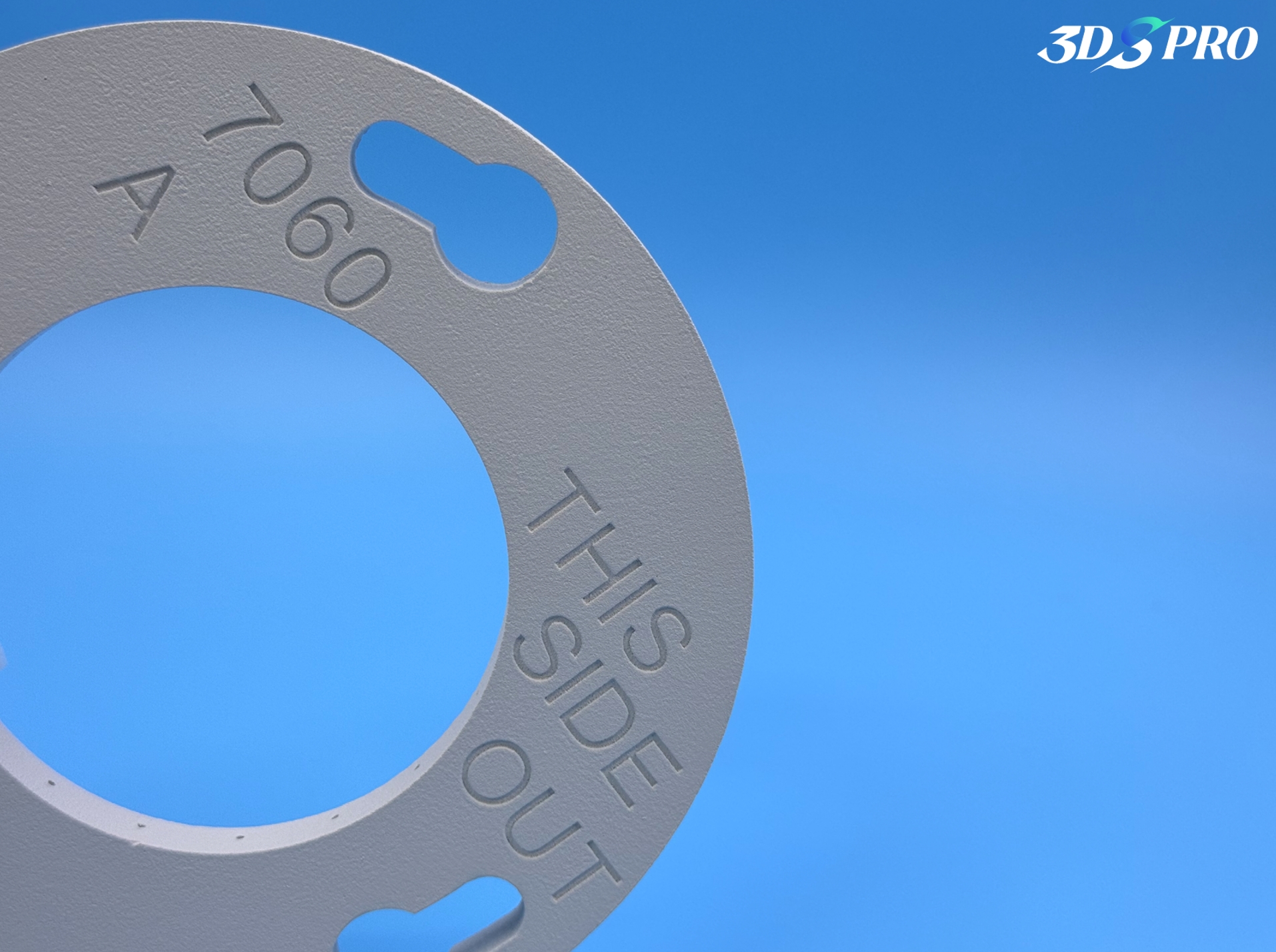

Quality Powder Coating at 3DSPRO

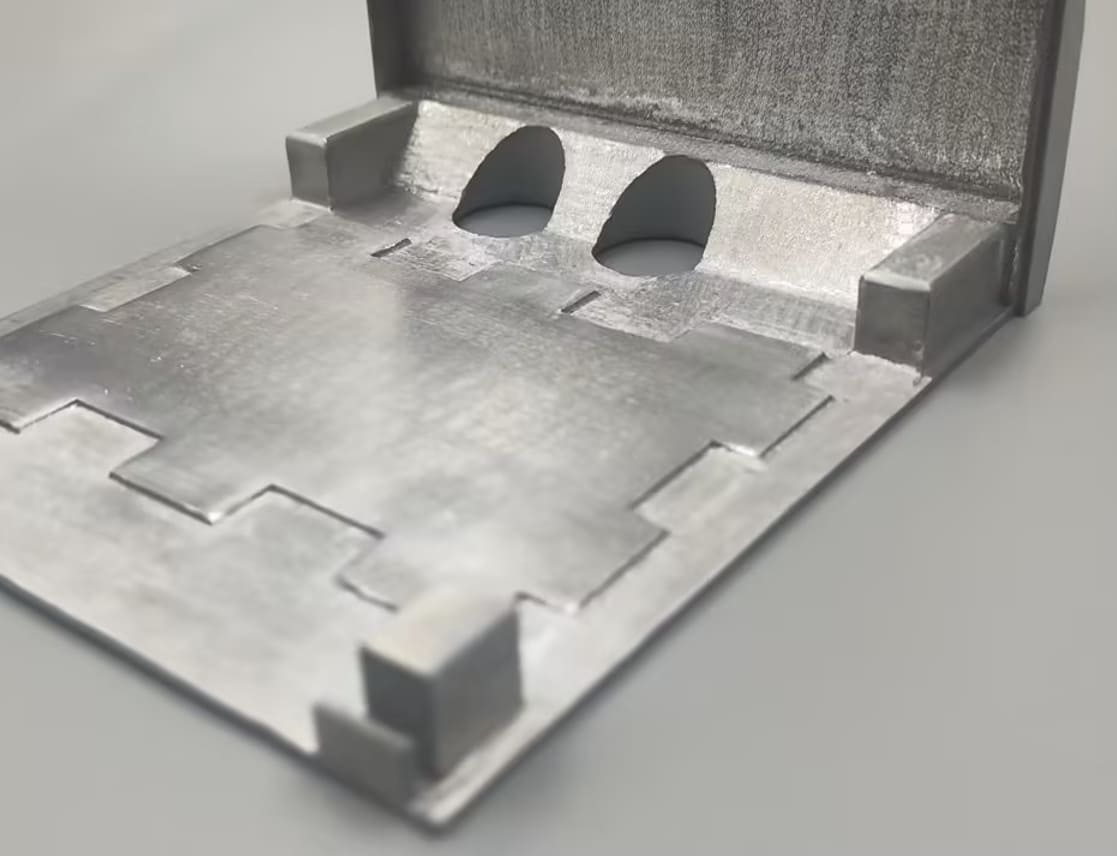

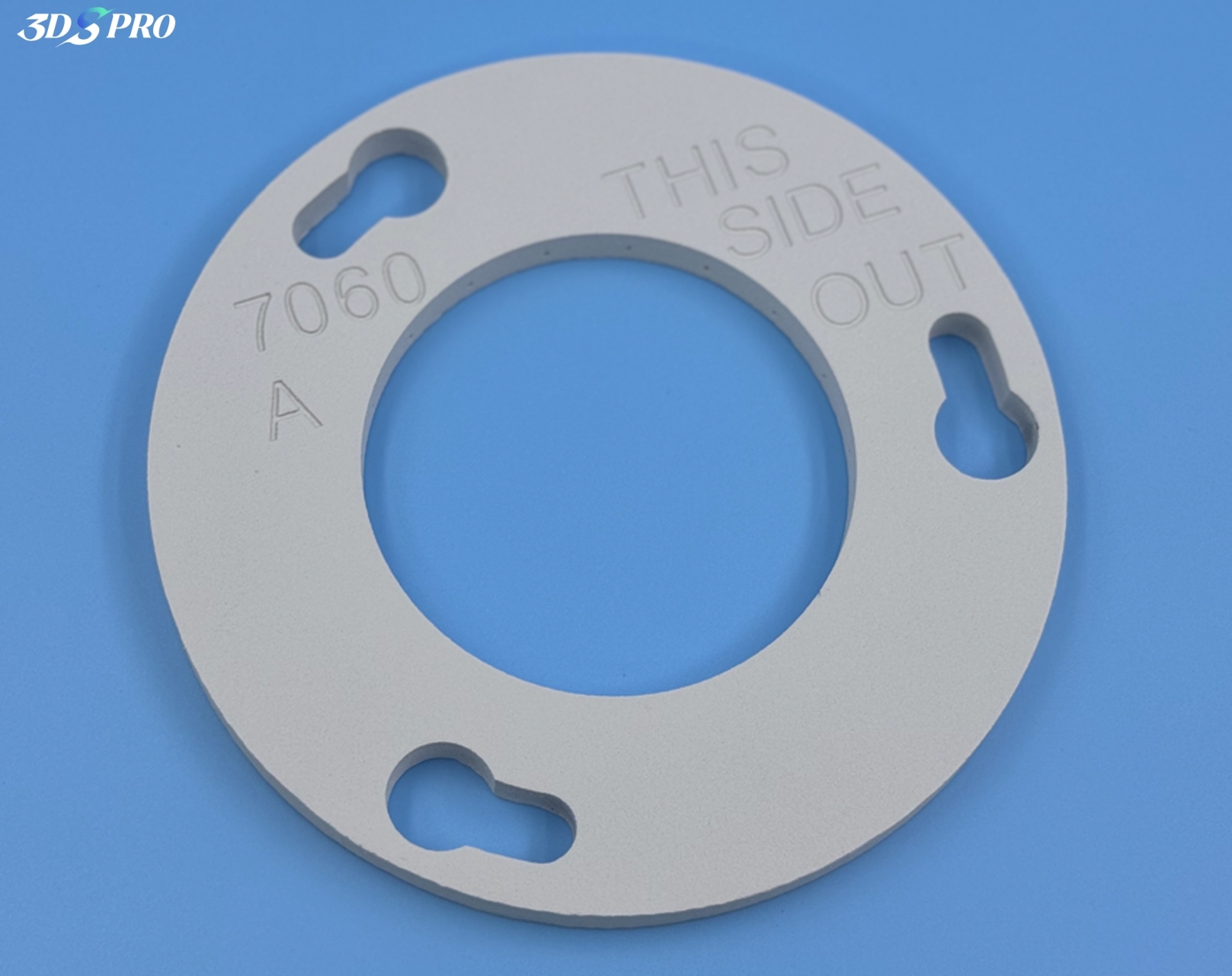

At 3DSPRO, we are committed to delivering top-tier powder coating service tailored specifically for 3D printed metal parts. Our 3D Plus™ powder coating service is designed to enhance the durability, appearance, and performance of metal printed parts.

Powder Coated Sample at 3DSPRO:

COMMENTS

- Be the first to share your thoughts!