3D printing software is the tool that transforms your digital designs into instructions a 3D printer can follow. Basically, it “slices” your 3D model into thin horizontal layers, creating step-by-step commands (often in G-code) that tell the printer exactly how to build your object, one layer at a time.

Alongside slicing, this software allows you to adjust print settings like layer height, speed, and infill density, ensuring you get the best quality print every time. Many programs also help identify and fix any design issues and add printing supports for complex shapes, making the process hassle-free for both beginners and professionals.

In simple terms, 3D printing software turns your creative ideas into a reality by bridging the gap between digital models and physical objects.

Types of 3D Printing Software

1. CAD Software (Design Stage)

Computer-Aided Design (CAD) software is where your 3D model comes to life. Whether you're creating a custom phone stand or a complex mechanical part, CAD tools help you design precise digital files.

Popular CAD tools for beginners:

• Tinkercad – Simple, browser-based, ideal for learning the basics.

• Fusion 360 – Powerful yet beginner-accessible, perfect for engineers or advanced hobbyists.

• SketchUp Free – Great for architectural and product design.

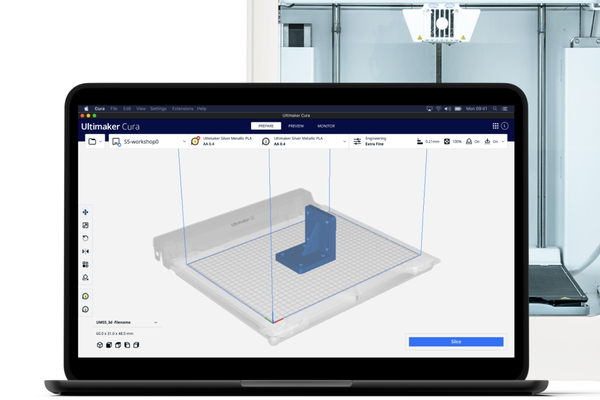

2. Slicing Software (Preparation Stage)

Before printing, your 3D model must be sliced into layers. Slicing software converts your model into G-code, which guides the printer on how to move and extrude filament.

Top slicer tools include:

• Ultimaker Cura – Free, user-friendly, with hundreds of adjustable settings.

• PrusaSlicer – Robust and intuitive, great for multi-material printing.

• Simplify3D – Premium option with advanced support control and print simulation.

3. Printer Control Software (Execution Stage)

Also known as host software, these programs allow you to manage the print job from your computer or remotely.

Examples:

• OctoPrint – Lets you control and monitor prints through a web browser.

• Repetier-Host – Offers real-time print management and multi-slicer support.

• Each tool plays a key role in turning your digital file into a successful 3D print.

Image Source: Tinkercad

Key Features to Look For

When choosing 3D printing software, especially as a beginner, it’s easy to get overwhelmed by options. Here are the key features that matter most:

1. Ease of Use

A user-friendly interface with drag-and-drop functionality, visual cues, and tutorials can dramatically reduce your learning curve.

2. File Compatibility

Ensure the software supports standard file formats like STL, OBJ, or 3MF, which guarantees that your model can move smoothly between the design, slicing, and printing stages.

3. Printer Compatibility

Choose software that works with your 3D printer or at least allows custom printer profiles.

4. Preset Profiles

Good slicer software offers preset configurations for different materials and printers, helping you get quality results right away.

5. Support Structure Tools

Whether auto-generated or manually adjustable, reliable support settings are crucial for complex prints.

6. Preview Mode

Look for slicing software that includes a layer-by-layer preview of how your model will be printed, which helps catch potential issues early.

7. Remote Monitoring & Control

If you're using cloud-based or Wi-Fi-connected printers, remote monitoring features are a huge plus.

Image Source: Ultimaker

Optimizing Software for Better Results

Use Correct Print Settings

Adjust layer height, temperature, and print speed based on your material and model complexity. Start with recommended defaults, then tweak as needed.

Orient Your Model Wisely

Changing the orientation of your model in the slicer can reduce the need for supports and improve surface quality.

Check for Model Errors

Use built-in tools or third-party software (like Microsoft 3D Builder or Netfabb) to detect and repair mesh issues before slicing.

Calibrate Your Printer Profile

Each printer has its quirks. Fine-tune your slicer settings over time for optimal results: retraction, wall thickness, infill patterns, etc.

Leverage Software Updates

Slicing and CAD software often release performance improvements, bug fixes, and new features. Keep your software up to date for the best experience.

Tips for Choosing the Right 3D Printing Software

|

Goal / Scenario |

Recommended CAD Software |

Recommended Slicer Software |

Why It’s a Good Fit |

|

Total beginner designing simple objects |

Tinkercad |

Cura |

Easy to learn, free, browser-based, and beginner-friendly |

|

Creating artistic or organic models |

Blender |

PrusaSlicer |

Blender offers artistic modeling; PrusaSlicer is powerful yet accessible |

|

Designing functional or mechanical parts |

Fusion 360 |

Cura or Simplify3D |

Fusion 360 is ideal for parametric design; slicers support detailed control |

|

Architectural modeling or product mockups |

SketchUp Free |

Cura |

Great for straight edges and structures, with basic slicing support |

|

Advanced users or those scaling up projects |

Fusion 360 / FreeCAD |

Simplify3D |

Offers full control, advanced slicing, and professional-level features |

|

Managing remote or multiple printers |

Any CAD Tool |

OctoPrint |

OctoPrint provides real-time monitoring and remote control over Wi-Fi |

|

You want expert help with printing itself |

Any software you prefer |

(Handled by 3DSPRO.com) |

3DSPRO checks, slices, prints, and ships your model with professional quality & support |

**Pro Tip: Start with the free tools first. They often offer more than enough to learn and grow—without the risk of spending on software you might not use.

Turning Your Designs into Reality with 3DSPRO 3D Printing Services

Once your design is ready, 3DSPRO makes it easy to transform your digital model into a professional-quality 3D printed part.

We specialize in high-precision 3D printing services using SLA, SLS, MJF and SLM 3D printing to meet a wide range of functional and aesthetic needs. Simply upload your 3D files, and our expert team will handle everything from file validation and slicing to print optimization.

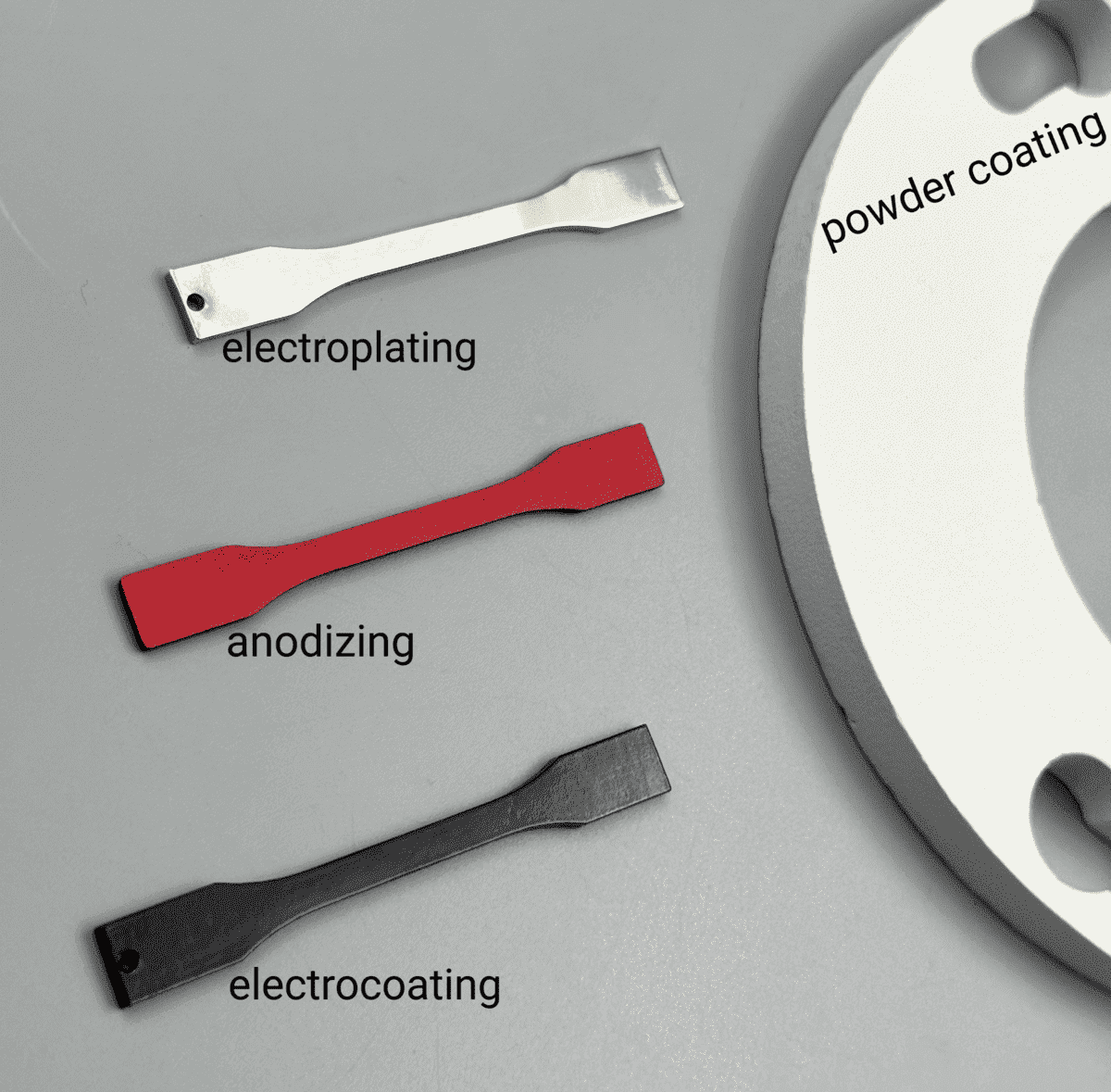

Beyond printing, we also offer a variety of surface finishing services—including sanding, vapor smoothing, painting, and polishing—to enhance the final look, feel, and durability of your part. Our goal is to help you achieve the perfect result without the hassle.

With quick turnaround times, material guidance, and a customer-first approach, we are your trusted partner in turning 3D ideas into tangible reality.

COMMENTS

- Be the first to share your thoughts!