When exploring the world of 3D printing, creating items that come into direct contact with food—such as utensils, containers, and molds—requires careful material selection. Not all 3D printing filaments labeled “food safe” deliver the same level of protection.

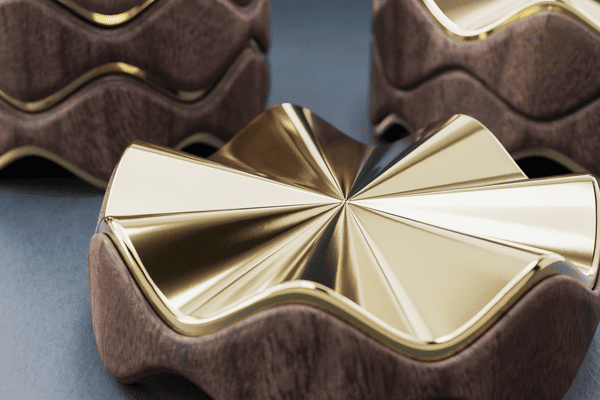

Image Source: Prusa

Types of Food Safe 3D Printing Filament

1. PLA-Based Filaments

Polylactic acid (PLA) is often touted as a beginner-friendly choice because it prints at relatively low temperatures and has minimal warping. Some manufacturers offer PLA blends specifically certified as food-safe. However, be aware that:

• Pros: Biodegradable; easy to print; wide color range.

• Cons: Low heat resistance (typically max service temperature around 50–60 °C); inherent porosity can trap bacteria unless layers are well-bonded or sealed.

If you choose PLA, opt for a brand that explicitly provides a Certificate of Analysis (COA) stating compliance with FDA CFR Title 21 (food-contact plastic) or EU Regulation 10/2011. Always verify that no additives (e.g., colorants, stabilizers) compromise food safety.

2. PETG and PETT Filaments

Polyethylene terephthalate glycol-modified (PETG) and polyethylene terephthalate triclolate (PETT) are more chemically resistant and heat-tolerant than PLA. Many PETG variants are marketed as food safe, but you must confirm via the datasheet:

• Pros: Higher glass transition temperature (≈ 70–80 °C); better chemical resistance (ideal for acidic or oily foods); relatively low porosity if printed correctly.

• Cons: Slightly more prone to stringing; requires fine-tuning of print settings to prevent layer gaps.

Look for PETG/PETT labeled with an NSF mark or FDA compliance. If you’re contracting a service to print your part, ask them to confirm their filament lot number matches an independent test.

3. Polypropylene (PP) Filaments

Polypropylene is inherently food-safe and widely used for consumer food containers. In filament form, PP can be challenging—especially regarding bed adhesion and warping:

• Pros: Excellent chemical resistance (no leaching of plasticizers); high heat tolerance (often dishwasher-safe up to 90 °C); naturally low moisture absorption.

• Cons: Tends to warp; fewer colors and options; not every printer’s heated bed can handle PP successfully.

If you have experience calibrating for PP (e.g., a bed that reaches ≥100 °C), this filament offers one of the most reliable routes to a truly food-safe part. Always confirm the brand provides an FDA-compliant COA.

4. Specialty Food-Safe Filaments

Some newer PLA or TPU blends incorporate certified food-safe additives or undergo manufacturing in clean-room environments. Examples include:

• Nylon Blends: Certain nylon filaments are formulated to meet food-contact regulations. Nylon’s flexibility can be useful for gaskets or flexible seals.

• Restaurant-Grade TPU: Flexible filaments designed for direct contact with food (e.g., sealing lids). They typically carry NSF 169 (Special Purpose Food Equipment and Devices) certification.

Because these specialty materials often command a premium price, evaluate whether your project truly needs flexibility or chemical resistance beyond what PLA, PETG, or PP can deliver.

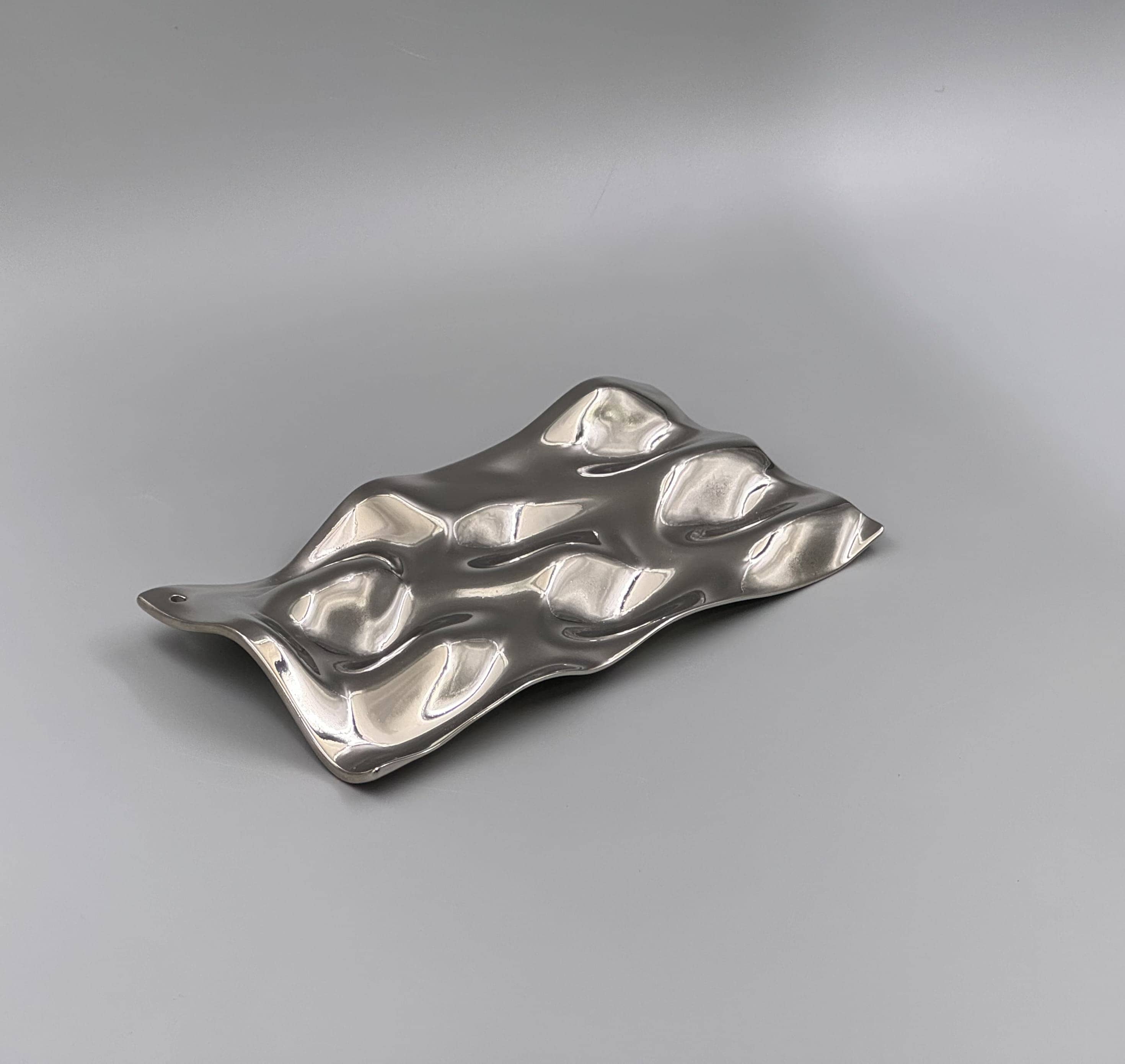

Image Source: 3DWare

How to Verify a Filament’s Food Safety

1. Review Manufacturer Datasheets

COA and Regulatory References: Look for explicit references to FDA CFR Title 21 (e.g., 21 CFR 177.1640 for PLA) or EU 10/2011. If a datasheet only claims “food-contact safe” without citing a regulation or lab report, proceed with caution.

Additive Listings: Ensure colorants, UV stabilizers, or other additives are themselves food-safe. Some dyes or softeners can leach harmful compounds into food.

2. Seek Third-Party Lab Testing

Migration Tests: These assess how much of a particular compound migrates from the plastic into an aqueous or fatty food simulant. A reputable filament brand will provide test results showing that migration levels fall below regulatory thresholds.

Heavy-Metal Analysis: Metals like lead or cadmium should be <100 ppb in the final print. Always ask for a readable PDF report.

3. Check Brand Reputation and User Reviews

Community Feedback: Search forums (e.g., r/3Dprinting, manufacturer’s online forums) for real users who have printed and tested the filament with actual food.

Consistency Across Batches: A single COA may not guarantee future lots meet the same standards. Work with suppliers who commit to batch-by-batch testing or guarantee batch numbers for traceability.

Are 3D Printed Resins Food Safe?

1. Standard vs. Food-Safe Resins

Generic photopolymer resins (for SLA/DLP printers) often contain unpolymerized monomers and photoinitiators that can leach into foods, making them unsafe out of the box. However, some manufacturers now sell food-safe SLA/DLP resins (frequently PEG-based) that:

• Pros: Produce ultra-smooth surfaces (fewer microcrevices than FDM), which reduces bacterial entrapment.

• Cons: Higher material cost; require extensive post-processing to eliminate residual monomers.

2. Critical Post-Processing Steps

Even if a resin carries a “food safe” label, it’s essential to:

• Wash Thoroughly: Use isopropyl or ethanol baths to remove uncured resin.

• Post-Cure Under UV: Ensure complete polymerization. Follow the manufacturer’s recommended duration (often 30–60 minutes at λ ≈ 405 nm).

• Apply a Barrier Coat: A thin layer of FDA-compliant epoxy or FDA-approved spray sealant minimizes porosity and blocks potential leaching sites.

3. Limitations of Resin Prints

• Brittleness: Most SLA prints aren’t ideal for mechanical loads (e.g., cutting tools, high-stress utensils). Use them for molds, short-term spoons, or sample cups, but avoid heavy-duty applications.

• Surface Scratches: Over time, small scratches can harbor bacteria. Regular inspection and re-coating are critical if you intend long-term food use.

Food Safe 3D Printed Metals

1. Common Metal Additive Technologies

Selective Laser Melting (SLM)/Direct Metal Laser Sintering (DMLS): Often used for stainless steel 316L, which is widely accepted for food-contact surfaces.

Binder Jetting + Sintering: Can produce stainless steel or aluminum parts but require careful post-sintering densification.

2. Key Considerations for Metal Prints

• Surface Roughness: Unpolished parts have micro-crevices that can trap food particles and bacteria.

• Electropolishing: Smoothens and passivates the surface, closing pores and eliminating free iron on the surface (critical for stainless steel).

• Passivation: Soaks the part in a mild acid solution (e.g., nitric acid) to remove surface contaminants and further enhance corrosion resistance.

3. Commonly Used Metals for Food-Safe Parts

• Stainless Steel 316L: The gold standard for cutlery, knives, and kitchen tools. After electropolishing and passivation, it meets NSF/ANSI 51 and can be used in professional kitchens.

• Aluminum Alloys (e.g., 6061): Lightweight and corrosion-resistant, but some people worry about aluminum leaching. Opt for anodized finishes if you choose aluminum.

• Titanium (Grade 2 or 5): Excellent biocompatibility high corrosion resistance—but high cost limits it to niche applications (e.g., specialized molds or implants).

Common Applications of Food Safe 3D Printing

1. Kitchen Utensils & Tools

• Spoons, Spatulas, and Custom Cutlery: A wall thickness of at least 2–3 mm helps prevent breakage. If you’re printing in PLA or PETG, design with gentle curves to minimize stress concentrators.

• Cookie Cutters & Molds: Polyester-based PETG or PP works well because of its chemical resistance. For intricate molds (e.g., custom chocolate shapes), SLA/DLP resin can capture fine details—just remember the barrier coat.

2. Food Storage & Organization

• Spice Jars & Containers: PETG or PP filaments are ideal for airtight fits. Accurate tolerances (±0.1 mm) matter for lids that need a snug seal.

• Bottle Openers & Custom Caps: Metal printing (316L) ensures longevity and dishwasher safety.

3. Tableware & Serveware Prototypes

• Cups, Plates, and Serving Bowls: PETG or polypropylene can handle warm foods. Always verify the maximum temperature of each filament before exposing it to hot liquids.

• Disposable Takeout Cutlery: Some cafés experiment with biodegradable PLA-based utensils—if they’re used once and discarded, sealant may be optional.

4. Edible Molds

• Chocolate & Candy Molds: SLA/DLP prints provide a glass-like finish when properly cured and sealed. For gummy molds, use food-grade silicone coatings over the resin print to facilitate easy demolding.

• Fondant & Cake-Toppers Molds: Nylon blends can be used for more flexible molds; just ensure a smooth finish to prevent sticking.

5. Restaurant-Grade Fixtures & Jigs

• Custom Salt Shakers, Spice Dispensers, and Honey Dippers: PP or PETG parts can handle repeated use and washing.

• Mounting Brackets for Kitchen Equipment: Metal 3D prints (316L) are ideal for custom brackets that meet exact fit requirements in a commercial kitchen environment.

Risks and Limitations to Be Aware Of

1. Porosity & Bacterial Growth

Even certified “food-safe” plastics can have microscopic gaps between layers. Increase wall thickness to 3–4 mm, set infill ≥50 %, and use at least three perimeters (walls). After printing, apply a food-grade sealant (e.g., FDA-approved epoxy spray) to create a non-porous surface.

2. Heat Resistance & Dishwasher Safety

• PLA Filaments: Often warp or soften at temperatures above 50–60 °C. It is not recommended for hot food or dishwashers.

• PETG Filaments: Generally safe up to 70–80 °C; may handle gentle dishwasher cycles on the top rack.

• PP Filaments: Can typically withstand dishwasher temperatures (≥90 °C). Always check the filament’s maximum service temperature on the datasheet.

3. Regulatory Compliance for Commercial Use

If you sell a 3D printed utensil, you may need a formal FDA registration, labeling, and adherence to Good Manufacturing Practices (GMP). Ensure your supplier or in-house process tracks filament lot numbers, COAs, and print conditions. Without traceability, you risk liability if a part fails.

4. Chemical Leaching & Additives

Certain PP blends may contain slip agents that can migrate into food over time. Brightly colored filaments may rely on pigments (e.g., cadmium-based reds) that aren’t food-safe. Besides, some UV-blocking additives aren’t tested for long-term food contact. Always verify each compound listed in the datasheet.

COMMENTS

- Be the first to share your thoughts!