Carbon fiber has long been used in industries like aerospace, automotive, and sports equipment for its exceptional strength‑to‑weight ratio. Traditionally, however, manufacturing carbon fiber composites required labor‑intensive processes such as lay‑up, curing, and machining.

By embedding carbon fiber into printable polymers, 3D printing can produce lightweight, durable, and customized carbon fiber parts directly from digital designs. 3D printing is reshaping how prototypes, functional components, and even end‑use products are made, offering a faster, more cost‑effective path to innovation.

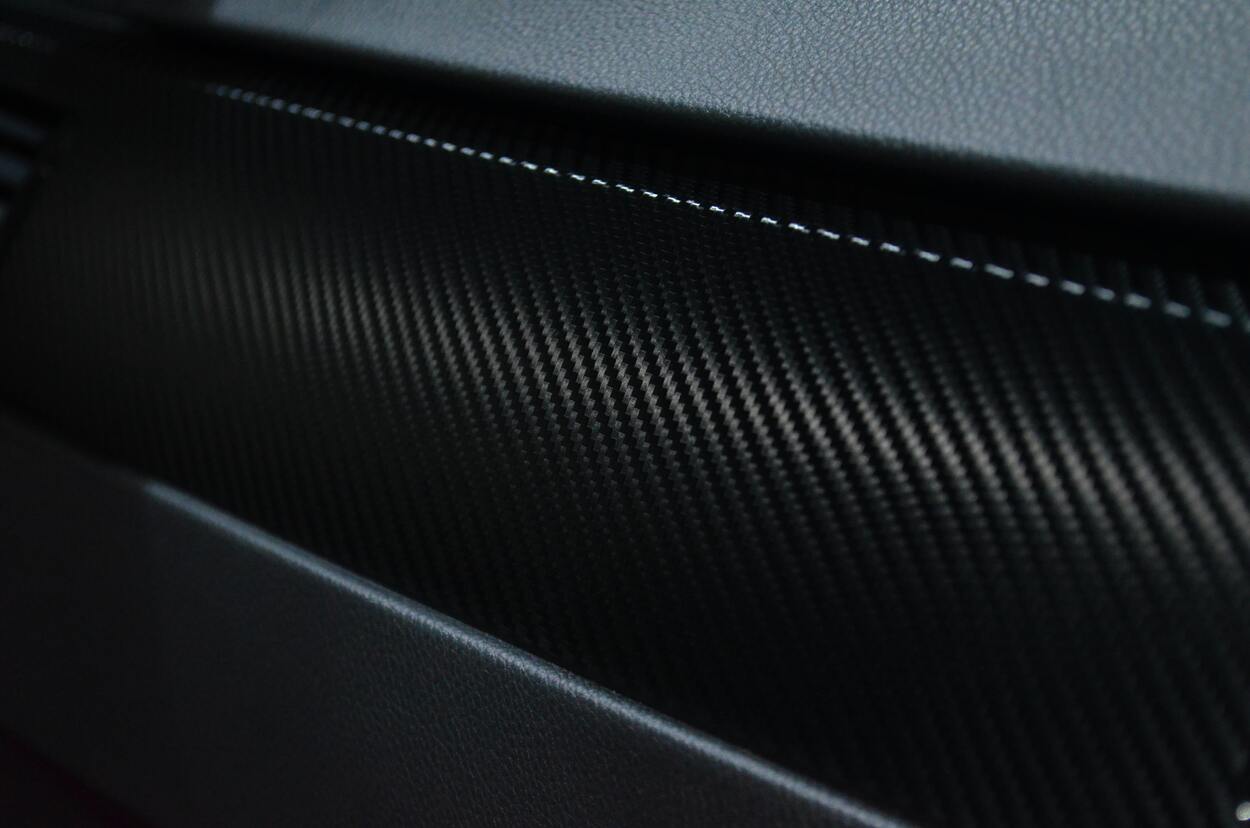

Image Source: Creapattern

What is Carbon Fiber 3D Printing?

Carbon fiber 3D printing refers to the process of reinforcing thermoplastic materials with carbon fiber, either in chopped form or as continuous strands, during 3D printing. Unlike traditional composite fabrication, which layers sheets of fiber and resin, 3D printing integrates reinforcement directly into the printing process.

1. Chopped Carbon Fiber: Short fibers mixed into filaments or powders. They improve stiffness and reduce warping but don’t achieve the full strength of continuous fibers.

2. Continuous Carbon Fiber: Long strands embedded within the printed part. This approach delivers superior strength and rigidity, rivaling aluminum in some applications.

Core Technologies in Carbon Fiber 3D Printing

Fused Filament Fabrication (FFF/FDM)

In FDM carbon fiber 3D printing, chopped carbon fibers are blended into thermoplastic filaments such as PLA, PETG, Nylon, or Polycarbonate. These filaments are extruded through a heated nozzle to build parts layer by layer. The chopped fibers enhance stiffness, reduce warping, and improve dimensional stability compared to standard plastics. While FDM is the most accessible and cost‑effective method, the mechanical strength achieved is lower than continuous fiber approaches, making it best suited for prototypes, jigs, fixtures, and lightweight functional parts.

Continuous Fiber Reinforcement (CFR)

CFR technology takes carbon fiber 3D printing to the next level by embedding long, continuous strands of carbon fiber within a thermoplastic matrix during the printing process. Specialized printers lay down these fibers alongside the base polymer, creating parts with exceptional strength and rigidity that can rival aluminum. CFR is ideal for structural applications in aerospace, automotive, and industrial tooling, where lightweight yet durable components are critical. The trade‑off is higher equipment cost and more complex printing requirements, but the performance benefits are significant.

Selective Laser Sintering (SLS)

SLS carbon fiber printing uses powdered polymers mixed with chopped carbon fiber, which are selectively fused by a high‑powered laser. SLS allows for highly accurate, complex geometries without the need for support structures. The addition of carbon fiber improves mechanical properties, making SLS parts stronger and more dimensionally stable than pure polymer prints. SLS is widely used for functional prototypes, housings, and lightweight components in industries that demand precision and durability.

Emerging Hybrid Methods

Beyond established techniques, new hybrid approaches are being developed to expand the possibilities of carbon fiber 3D printing. Resin‑based systems are experimenting with fiber reinforcement to combine the smooth surface finish of stereolithography with composite strength. Multi‑material extrusion methods are also being explored, enabling combinations of metals, polymers, and fibers in a single build. While still experimental, these innovations promise to deliver even higher-performance parts and broaden the range of applications for carbon fiber additive manufacturing.

Carbon Fiber 3D Printing Materials

The choice of material determines the performance of carbon fiber 3D printed parts.

Carbon Fiber Reinforced Filaments

• PLA + CF: Easy to print, good stiffness, but brittle.

• PETG + CF: Balanced strength and flexibility.

• Nylon + CF: Tough, wear‑resistant, widely used in industrial tooling.

• Polycarbonate + CF: High impact resistance and heat tolerance.

Continuous Carbon Fiber Materials

• Prepreg tapes or specialized filaments designed for CFR printers.

• Provide aerospace‑grade strength and stiffness.

High‑Performance Polymers with Carbon Fiber

• PEEK, PEKK, ULTEM reinforced with carbon fiber.

• Exceptional chemical resistance, high temperature tolerance, and mechanical performance.

• Used in aerospace, medical implants, and oil & gas applications.

Material Comparison Highlights

• PLA + CF: Affordable, easy, but limited durability.

• Nylon + CF: Versatile, strong, widely adopted.

• PEEK + CF: Premium, high‑performance, costly but unmatched in demanding environments.

Pros and Cons Cheat Sheet

|

Pros |

Cons |

|

High strength‑to‑weight ratio |

Higher material and printer costs |

|

Lightweight yet durable parts |

Nozzle wear due to abrasive fibers |

|

Reduced warping and shrinkage |

Limited scalability for mass production |

|

Design freedom with complex geometries |

Surface finish may require post‑processing |

|

Ideal for aerospace, automotive, and tooling |

Continuous fiber requires specialized printers |

Key Applications of 3D Printed Carbon Fiber

Aerospace

Lightweight brackets, UAV components, satellite housings.

Reduces fuel consumption and increases payload efficiency.

Prepreg tapes

Structural parts, custom tooling, lightweight panels.

Enables rapid prototyping and performance optimization.

Medical

Prosthetics, surgical tools, orthopedic supports.

Combines strength with patient‑specific customization.

Consumer Products

Sports equipment (bike parts, rackets), drones, and electronics housings.

Offers durability and sleek design for lifestyle products.

Industrial Tooling

Jigs, fixtures, molds, and robotic end‑effectors.

Cuts lead times and costs compared to machined metal tools.

FAQs

Q: Is carbon fiber 3D printing stronger than metal printing?

A: Not always. Continuous carbon fiber can rival aluminum in stiffness and strength, but metals like titanium or steel still outperform composites in load‑bearing applications.

Q: Can any 3D printer use carbon fiber filaments?

A: Most FDM printers can handle chopped carbon fiber filaments, but they require hardened steel nozzles to resist abrasion. Continuous fiber printing, however, needs specialized hardware.

Q: How expensive is carbon fiber 3D printing?

A: Costs vary. Reinforced filaments are moderately priced, while continuous fiber systems and high‑performance polymers can be significantly more expensive. The trade‑off is reduced weight and improved performance.

Q: What industries benefit most from carbon fiber 3D printing?

A: Aerospace, automotive, medical, and industrial tooling are leading adopters, but consumer products are also growing rapidly.

Q: Do carbon fiber 3D printed parts require post‑processing?

A: Yes, depending on the application. While many parts are functional straight off the printer, sanding, coating, or machining may be needed to improve surface finish or dimensional accuracy.

Q: How durable are carbon fiber 3D printed parts compared to injection‑molded plastics?

A: Carbon fiber composites are generally stiffer and more resistant to wear and deformation than standard injection‑molded plastics, making them ideal for demanding environments.

Q: Can carbon fiber 3D printing be used for mass production?

A: Currently, it’s better suited for prototyping, tooling, and low‑volume production. Scaling to mass production is limited by speed and material costs, though hybrid manufacturing approaches are emerging.

COMMENTS

- Be the first to share your thoughts!