3DSPRO Helped Various Industries Innovate

Innovation doesn’t happen in isolation. It thrives when bold ideas meet the right tools to bring them to life. At 3DSPRO, we’ve seen firsthand how advanced 3D printing can transform industries, turning ambitious concepts into tangible solutions that push boundaries. From precision engineering to artistic expression, our work spans a remarkable range of applications, each one proving that additive manufacturing is no longer just a prototyping tool but a production powerhouse.

Over the years, we’ve partnered with pioneers across technology, design, and manufacturing to solve challenges that traditional methods couldn’t. Whether it’s enabling scientists to explore the future of quantum computing, helping engineers build stronger and lighter vehicles, or giving artists new ways to express creativity, 3DSPRO has become a trusted collaborator in shaping what’s next.

This article highlights some of the most exciting projects we’ve been part of, each of which each one a story of how 3D printing accelerates innovation, from prototype to production.

Quantum Computer Casing

• Full Product Showcase: Quantum Motion has unveiled the industry’s first full‑stack silicon CMOS quantum computer, seamlessly integrating cryogenic systems, measurement electronics, and silicon‑based qubits into a unified platform. The accompanying image highlights the complete product; however, only one of the casing structures was manufactured by 3DSPRO.

Image Source: Quantum Motion

• What 3DSPRO 3D Printed: A sculptural metal casing with articulated front doors, designed by Felix to house critical measurement equipment and cryogenic containment systems. The casing integrates intricate, organic geometries and subtle patterns inspired by silicon chip architecture, creating a kinetic visual effect that reflects principles of quantum mechanics.

Image Copyright © 3DSPRO Limited. All rights reserved.

• Process: Selective Laser Melting

• Material: Stainless Steel 316L

• Surface Finishing at 3DSPRO: Polishing

• Customer Feedback: "Working with 3DSPRO was a very positive experience. Their team helped me optimize my designs so the 3D metal prints succeeded without losing detail, and they gave practical advice on staying within budget while maintaining high quality. Because metal additive manufacturing is still relatively new, having a partner who understands both the material and geometric limitations was invaluable. I look forward to collaborating with them again on future projects."

Comprehensive Solution for Solar Energy

• What 3DSPRO 3D Printed: Key components for an advanced solar energy storage system, including the main chassis, chassis sealing gaskets, and multiple spare parts. The collaboration enabled rapid prototyping, functional testing, and final production of durable, high-performance components tailored to the customer's requirements.

• Process:

Chassis: Selective Laser Melting

Gaskets: Stereolithography + Vacuum Casting

Spare Parts: Stereolithography + Selective Laser Sintering

• Material:

Chassis: Aluminum AlSi10Mg

Gaskets: Quality Resin White

Spare Parts: TPU White, PA 12 White, PA 12 Black, High-Detailed Resin White, Quality Resin White

• Surface Finishing at 3DSPRO: Powder coating for the chassis.

• Customer Feedback: "3DSPRO’s ability to combine multiple 3D printing technologies with traditional processes gave us exactly what we needed. From the powder-coated aluminum chassis to the flexible sealing gaskets and precision spare parts, every component met our standards for durability and performance. Their iterative, customer-focused approach made the collaboration seamless and highly effective."

Image Copyright © 3DSPRO Limited. All rights reserved.

Motorbike Subframe

• What 3DSPRO 3D Printed: A custom motorbike subframe designed to be both functional and visually striking. The large, intricate structure was tailored to the customer's unique design vision, blending artistry with engineering precision.

• Process: Selective Laser Sintering

• Material: Nylon PA 12 Black

• Surface Finishing at 3DSPRO: Original

• Customer Feedback: "Really high quality and so easy to work with. Being able to communicate directly with the engineers made the process much easier and more personal. The result was way above what I was expecting as my requirements were all met, with no layer lines and perfect dimensional accuracy. I’m really happy with the overall outcome."

Image Copyright © 3DSPRO Limited. All rights reserved.

Golden Boot

What 3DSPRO 3D Printed: A full-scale, “drinkable” golden boot designed as both a functional vessel and a sculptural award piece. The boot featured hollow internal structures, engraved and embossed details, and a form true to the actual shoe size of professional footballer Edson Álvarez.

• Process: Selective Laser Melting

• Material: Aluminum 6061

• Surface Finishing at 3DSPRO: Bead Blasting

• Customer Feedback: "Partnering with 3DSPRO gave us the confidence to take on a project that many others had turned down. The result was a life-size, gold-plated, 3D printed boot that exceeded expectations in both function and appearance. It was incredibly motivating to see such a challenging idea come to life, and the collaboration was smooth, professional, and inspiring."

Image Copyright © 3DSPRO Limited. All rights reserved.

Food Packaging

• What 3DSPRO 3D Printed: Premium food packaging components for Saudi dates brand NUA, designed by Lazy Snail. The project included two award-winning designs, Dunes and Stem, which combined stainless steel with wood and marble to create luxurious, functional packaging.

• Process:

Prototypes: Selective Laser Melting

Serial Batches: Stamping + CNC Machining

• Material: Stainless Steel 316L

• Surface Finishing:

Prototypes: Mirror Polishing

Image Copyright © 3DSPRO Limited. All rights reserved.

Serial Batches: Polishing + PVD Titanium Coating (custom gold color)

Image Copyright © 3DSPRO Limited. All rights reserved.

• Customer Feedback: "3DSPRO delivered exactly what we needed: high-quality metal components with flawless finishes, on a very tight timeline. Their ability to adapt from additive prototypes to conventional manufacturing for serial batches was impressive, and the results exceeded expectations. Thanks to their expertise, our packaging designs not only came to life but also won international awards."

Light Sculptures

• What 3DSPRO 3D Printed: Aluminum light sculptures for the “Echo” series, part of Batten & Kamp’s From a Distance exhibition. The works were created by 3D scanning natural branches from sites of personal significance, then transforming them into suspended sculptural lighting pieces that merge memory, place, and technology.

• Process: Selective Laser Melting

• Material: Aluminum AlSi10Mg

• Surface Finishing: Sandblasting

• Customer Feedback: "3D printing allows us to work with complicated natural and manmade forms, and by printing in metals, we can refine the finish to elevate them into something special and unrecognizable. Using 3D printing feels limitless in what we can imagine and produce. Working with 3DSPRO was very smooth; we felt like we had a true partner in the manufacturing process."

Image Copyright © 3DSPRO Limited. All rights reserved.

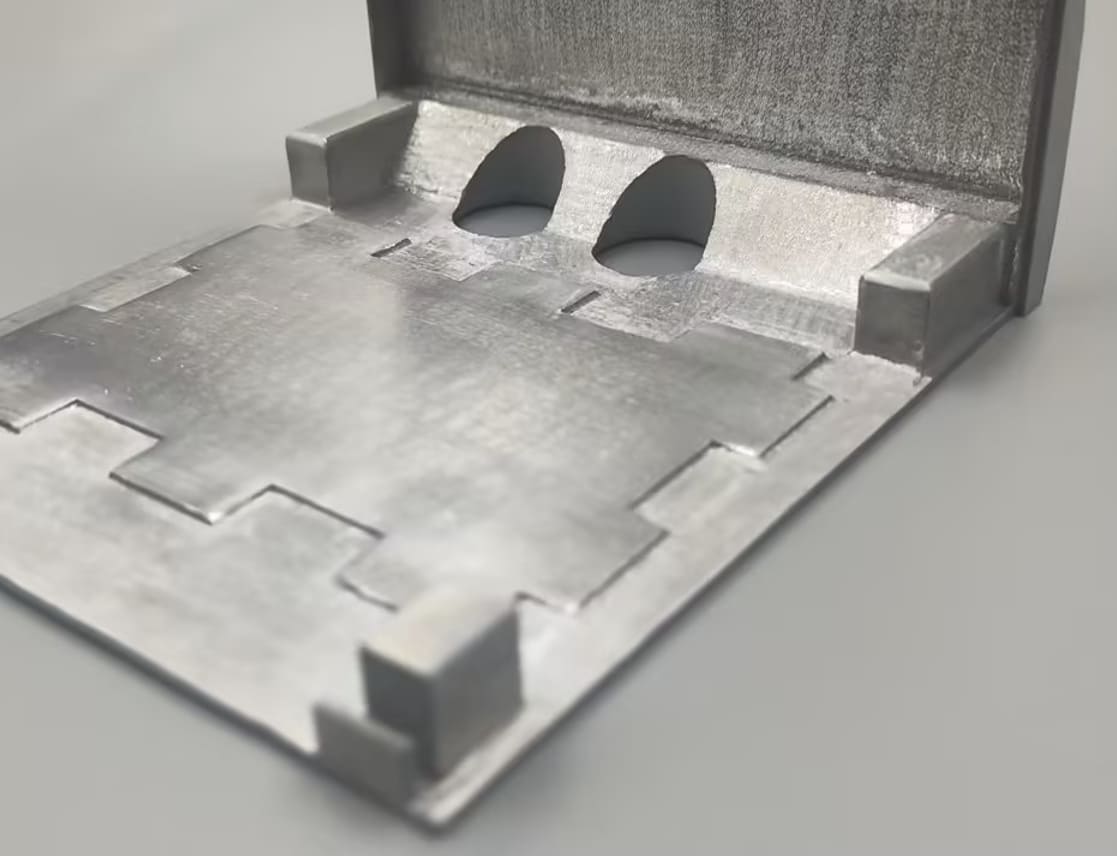

Tight-Fitting Aerospace Parts

• What 3DSPRO 3D Printed: A precision-engineered aluminum cover designed to protect the ADI-E payload’s flight computer and sub-payloads during ResearchSat’s MAPHEUS 14 suborbital rocket mission. The part required exact tolerances to ensure a tight fit and withstand the dynamic loads of spaceflight.

• Process: Selective Laser Melting

• Material: Aluminum AlSi10Mg

• Surface Finishing: Brushed Polishing

• Customer Feedback: "3DSPRO delivered a flight-ready part with the precision and speed we needed. Their dimensional checks and quality assurance gave us confidence that the cover would integrate seamlessly with the rest of the assembly. The fast turnaround and clear communication kept our project on schedule, and the final part performed exactly as required during the mission."

Image Copyright © 3DSPRO Limited. All rights reserved.

COMMENTS

- Be the first to share your thoughts!