Resin 3D Printing Materials

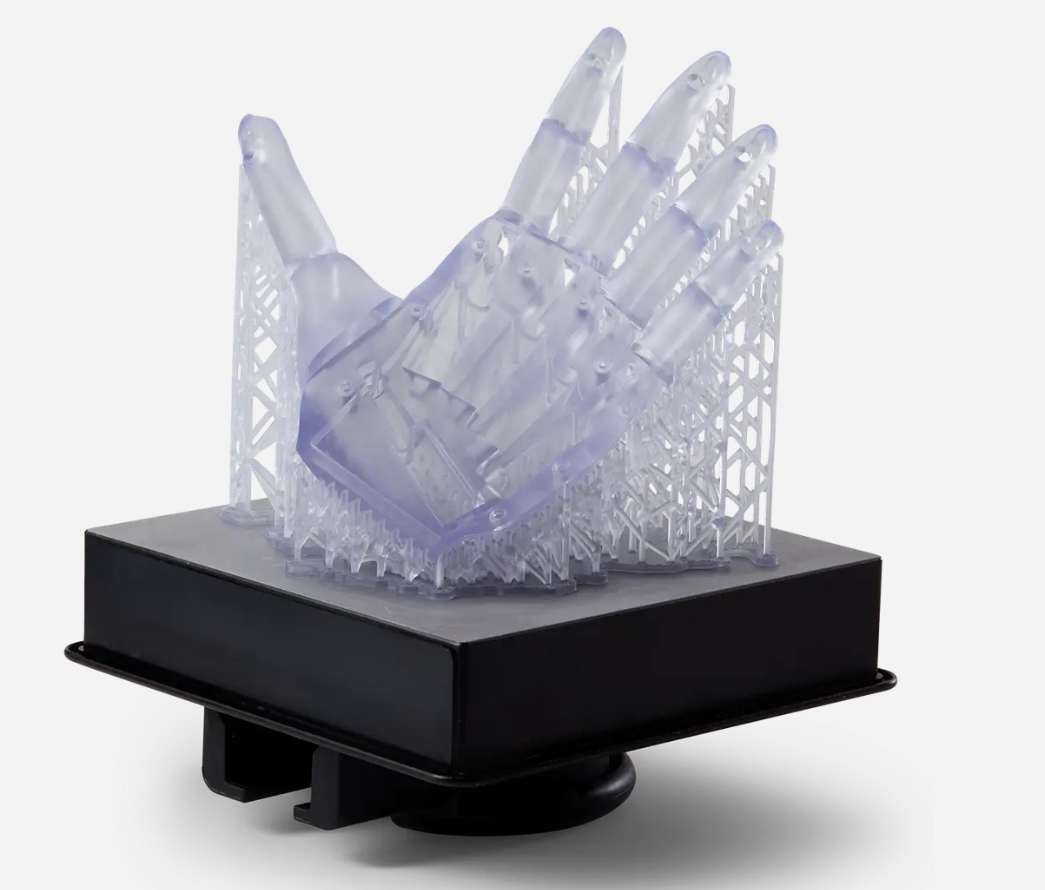

Resin 3D printing also referred to as Stereolithography (SLA) or digital light processing (DLP), is an additive manufacturing process that uses liquid resin as the raw material. Unlike traditional filament-based 3D printing, where plastic filaments are melted and deposited layer by layer, resin 3D printing cures liquid resin layer by layer using UV light or other light sources.

One of the most compelling benefits of resin 3D printing is its capacity to create intricately detailed parts with exceptionally smooth surfaces. This is made possible by the liquid resin, which allows for the creation of fine features, intricate geometries, and excellent surface finishes. The practical advantages of resin 3D printing make it a valuable tool in a variety of applications.

In this comprehensive Resin 3D Printing Materials Guide, we’ll explore various types of resin materials.

Standard Resin

Standard resin is a versatile material commonly used in 3D printing.

Key Features:

● Versatility: Standard resin is suitable for general-purpose applications. Whether you're creating concept models, functional prototypes, or artistic pieces, this resin type provides a good balance of strength and surface finish.

● Ease of Use: Standard resin is relatively straightforward to work with. It's compatible with a range of SLA and DLP 3D printers, ensuring accessibility for both novices and seasoned users.

● Surface Finish: When cured, standard resin produces parts with a smooth surface, allowing for intricate details and fine features.

● Color Options: Standard resin comes in various colors, allowing you to select the one that best fits your project.

At 3DSPRO, we offer Quality Resin as an alternative to standard resins at the same price as standard resins on the market. With our Quality Resin, you get stronger parts at no extra cost.

3DSPRO Quality Resin White (Somos® Ledo 6060)

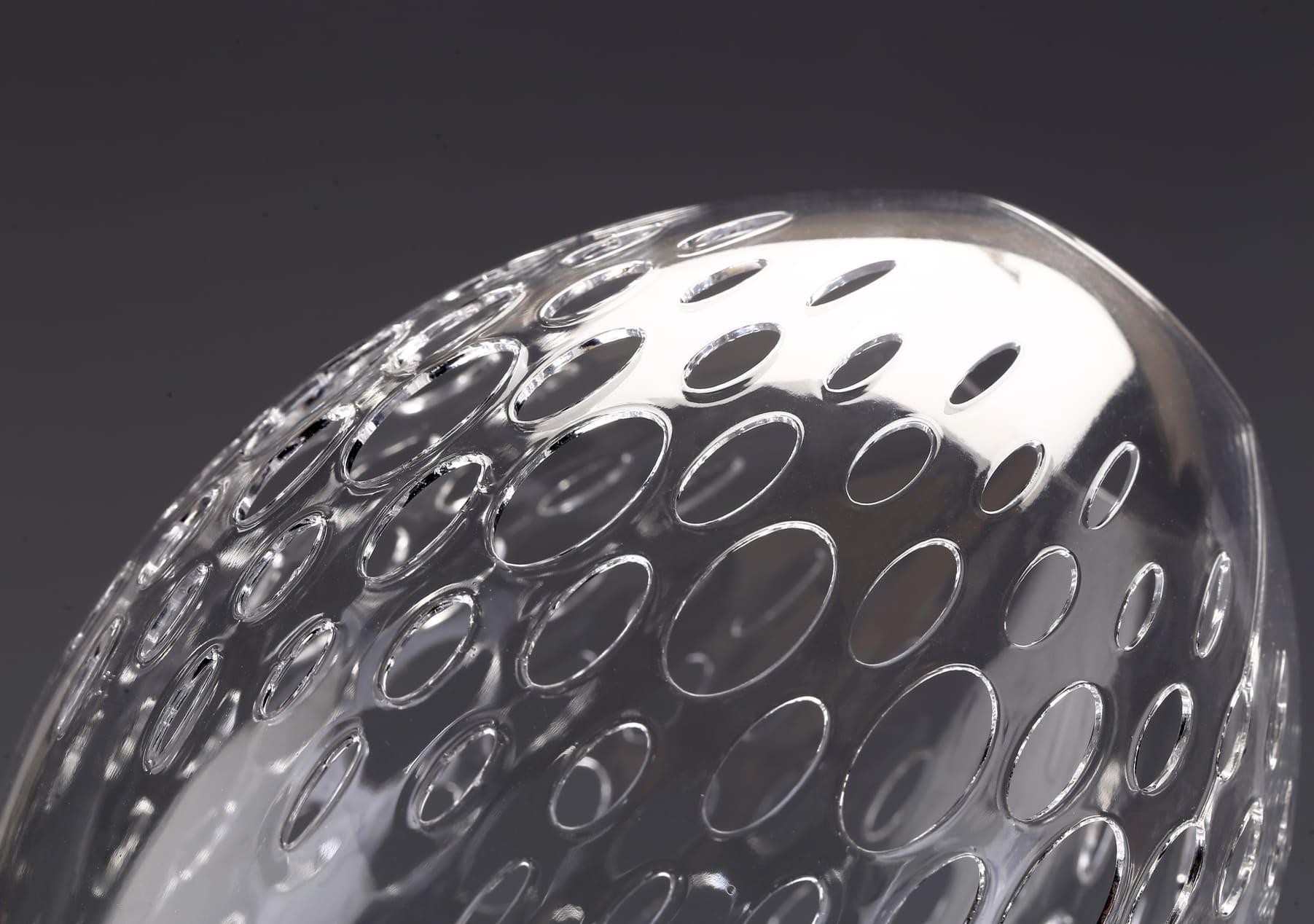

Clear Resin

Clear resin is a fascinating material for its translucent properties.

Key Features:

● Transparency: Clear resin produces parts that are transparent or translucent. This feature makes it ideal for creating see-through prototypes, lenses, and other applications where optical clarity is essential.

● Visual Prototyping: Clear resin, with its precision and ability to showcase internal structures or demonstrate fluid flow, instills confidence in creating visually accurate models. Architects, product designers, and engineers often rely on it for concept validation.

● Artistic Applications: Artists and jewelry designers appreciate clear resin's ability to capture intricate details. Whether it's a delicate pendant or a miniature sculpture, the transparency adds an elegant touch.

● Light Transmission: Clear resin allows light to pass through, making it suitable for light-guiding components, such as light pipes or diffusers.

3DSPRO Premium Clear Resin (Somos® WaterShed® XC 11122)

Tough Resin

Tough resin is a remarkable material used in 3D printing for its durability and impact resistance.

Key Features:

● Strength: Tough resin is engineered to withstand mechanical stress. It produces parts that are sturdy and robust, making it suitable for functional prototypes and components that need to endure handling or assembly.

● Engineering Applications: Engineers often turn to tough resin when creating jigs, fixtures, and tooling. These parts can withstand repeated use and maintain their integrity.

● Impact Resistance: Tough resin provides excellent impact resistance, making it ideal for applications where parts may experience sudden forces or collisions.

● Flexibility: While not as flexible as rubber-like resins, tough resin strikes a balance between rigidity and flexibility. It’s a great choice for parts that require some give without sacrificing strength.

In addition to tough resin, ultra-tough resin is also an option. Ultra-tough resins offer even greater strength and durability for demanding applications. These materials are designed to withstand extreme conditions and provide exceptional performance in various industries. Ultra-tough resin is ideal for creating robust functional prototypes, engineering components, and durable end-use products in various industries.

3DSPRO Ultra-Tough Resin (Somos® Taurus™)

High-temperature Resistant Resins

High-temperature resistant resins, including phenolic, epoxy, polyimide, and cyanate ester, are engineered to withstand extreme heat environments. They exhibit exceptional thermal stability and retain their mechanical properties at elevated temperatures.

Key Features:

● Exceptional Thermal Stability: High-temp resins can withstand extreme heat conditions without compromising structural integrity.

● Chemical Resistance: High-temp resins are resistant to aggressive chemicals, acids, and bases.

● Flame Retardancy: Some high-temperature resins, such as phenolics, are inherently flame-retardant. They provide added safety in fire-prone environments.

● Electrical Insulation: Some high-temp resins, like cyanate esters, exhibit excellent electrical insulation properties. They are used in electronic components and other electrical applications.

● Low Moisture Absorption: High-temp resins absorb minimal moisture, making them suitable for high-humidity environments. Moisture absorption can weaken materials, but high-temp resins mitigate that risk.

3DSPRO High-temp Resistant Resin

Flexible Resin

Flexible resin is known for its elasticity properties.

Key Features:

● Elasticity: Flexible resin produces parts with varying levels of flexibility. Unlike rigid materials, it can bend and stretch, making it suitable for applications where parts need to absorb impact or conform to irregular shapes.

● Gaskets and Seals: Engineers often turn to flexible resin when designing gaskets, seals, and O-rings. These components require both resilience and a snug fit, which flexible resin provides.

● Articulated Models: Whether you’re creating action figures, articulated toys, or wearable accessories, flexible resin allows for movable joints. It’s perfect for bringing your designs to life.

● Comfortable Prototypes: Flexible resin ensures a comfortable user experience when designing ergonomic handles, grips, or wearable devices. It mimics the feel of rubber or soft plastics.

Image Source: Formlabs Flexible 80A Resin

Water-washable Resin

Water-washable resin is a convenient material used in 3D printing for its post-processing simplicity.

Key Features:

● Easy Cleanup: Water-washable resin allows you to rinse off uncured resin with water. Unlike other resins that require harsh chemicals or alcohol, this type simplifies the cleaning process.

● No Solvents Needed: Say goodbye to messy solvents! Water-washable resin eliminates the need for toxic or flammable substances during post-processing.

● Ideal for Beginners: If you’re new to resin 3D printing, water-washable resin is a friendly choice. It reduces the learning curve and encourages experimentation.

● Environmentally Friendly: By using water as the cleaning agent, you contribute to a more eco-friendly printing process.

Image Source: Elegoo Water-washable Resin

Dental Resin

Dental resin is a specialized material designed specifically for dental applications in resin 3D printing.

Key Features:

● Biocompatibility: Dental resin meets stringent biocompatibility requirements. It is safe for use in the oral cavity, making it suitable for creating dental prosthetics such as crowns, bridges, veneers, and dentures.

● Accuracy and Precision: Dentists and dental technicians rely on dental resin to produce highly accurate and precise models. Whether it’s a custom-fit crown or an orthodontic appliance, dental resin ensures a snug fit.

● Tooth-Colored Options: Dental resin comes in various shades to match natural teeth. It allows for seamless integration with existing dentition, resulting in aesthetically pleasing restorations.

● Post-Processing: After 3D printing, dental resin undergoes additional steps such as curing, polishing, and finishing. These processes ensure optimal fit and function.

Image Source: Formlabs Dental LT Clear Resin (V2)

Ceramic-filled Resin

Ceramic-filled resin is a unique material that combines the properties of both resins and ceramics.

Key Features:

● High-Temperature Resistance: Ceramic-filled resin combines the benefits of ceramics with the flexibility of resin. It’s an excellent choice for parts that need to withstand high temperatures, whether you’re creating components for aerospace, automotive, or industrial applications.

● Complex Geometries: The addition of ceramic particles allows for intricate and complex geometries. You can 3D print parts with fine details, thin walls, and internal channels, all while maintaining ceramic-like properties.

● Thermal Insulation: Ceramic-filled resin offers thermal insulation properties, making it ideal for applications where precise temperature regulation is essential. Think of insulating sleeves, heat shields, or components near hot machinery.

● Chemical Resistance: Ceramics are known for their chemical resistance. By incorporating ceramic particles into resin, you get a material that can withstand exposure to various chemicals and corrosive environments.

Image Source: Zortrax Ultracur3D® RG 3280

Check out Full SLA 3D Printing Materials List at 3DSPRO

COMMENTS

- Be the first to share your thoughts!