3D printing has moved well past the experimental runway stunt stage and into a meaningful tool for designers. From fully articulated, museum-acquired dresses to lattice midsoles that power mainstream sneakers, 3D printing gives designers new geometry, customization, and supply-chain options.

Top Brands of 3D Printed Clothes

Iris van Herpen

Iris van Herpen is often the first name people think of when 3D printing and fashion appear in the same sentence. Iris van Herpen blends couture craft with digital production. Her studio began experimenting with printed elements more than a decade ago and continues to combine handwork, laser cutting, and printed components to produce sculptural runway pieces that read as wearable art.

Danit Peleg

A designer who pushed accessible, consumer-facing 3D fashion, Danit Peleg became known for developing workflows that let desktop printers produce wearable garments and for advocating on-demand, customizable clothing production. Her work helped move the conversation from gallery experiments to practical attempts at printed ready-to-wear.

Nervous System Studio

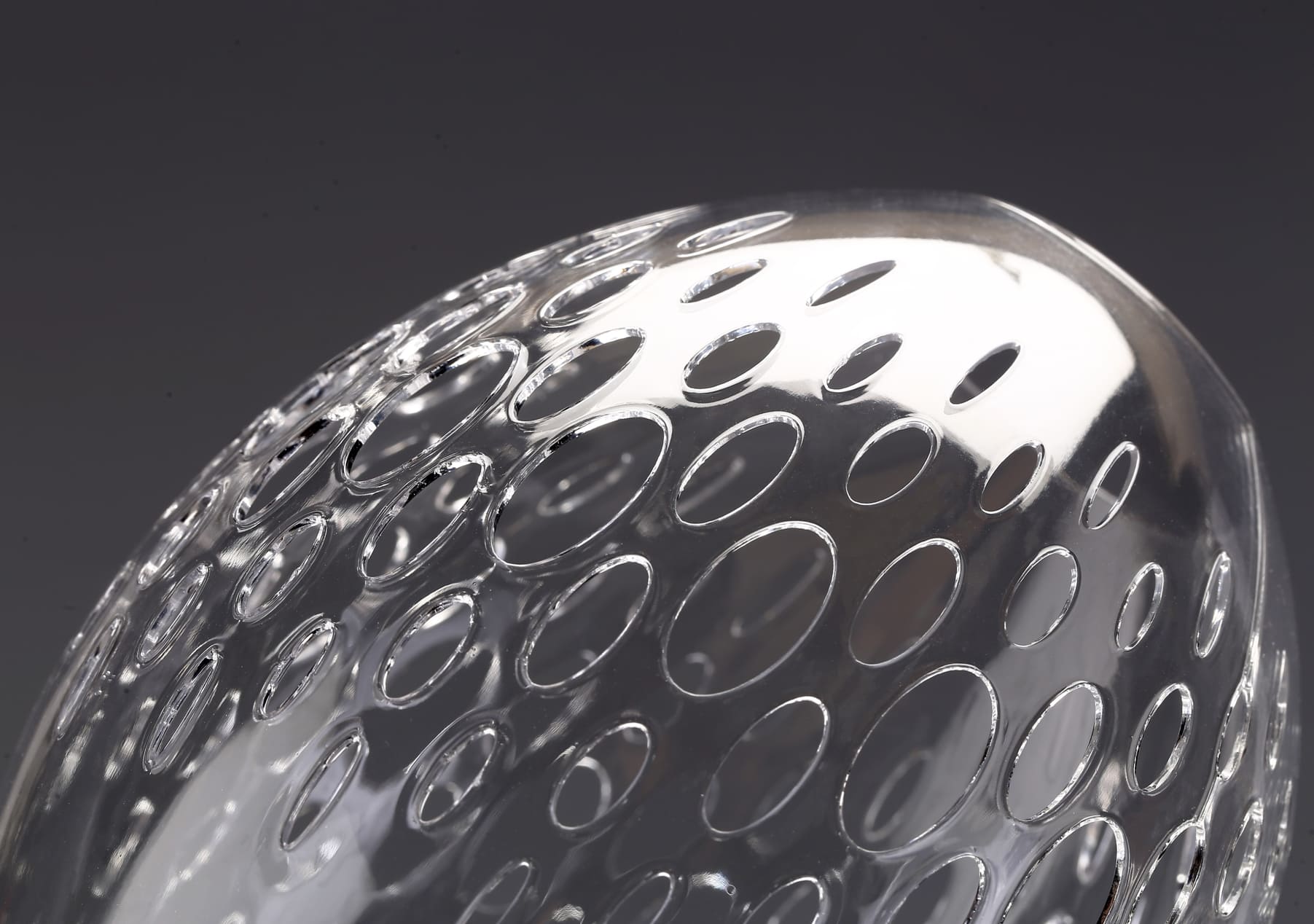

The studio created the famous Kinematics dress, a single, hinge-linked nylon piece printed as one object that behaves like fabric through thousands of tiny interlocking tiles. The project is a classic demonstration of how clever geometry and software can make rigid materials feel textile-like.

Image Source: Iris van Herpen

How 3D Printed Garments Are Made

Printing Techniques Used in Fashion

Selective Laser Sintering (SLS)

SLS fuses powdered materials with a laser. It’s prized in fashion for producing flexible, interlocking lattices and articulated parts that behave more like fabric than brittle prints. SLS is a favorite for wearable pieces that need many small, moving connections.

Stereolithography (SLA)

Resin printers deliver very high detail and smooth surfaces, useful for decorative elements and jewelry, but many photopolymers remain less comfortable or durable for prolonged skin contact unless specially formulated.

Fused Deposition Modeling (FDM)

Desktop FDM printers are inexpensive and accessible, and designers use them to prove concepts and create printed garments. FDM typically produces more rigid parts and visible layering, so it’s most often used for trims, proofs of concept, or when using flexible filaments.

Material and Binder Jetting

These processes allow color, gradient, and multimaterial possibilities. They’re less widespread for full garments but useful for accessories and prototype surface effects.

Hybrid Workflows

Most commercially wearable pieces combine printed parts with textiles. Printed meshes stitched to fabric, printed reinforcements at stress points, or printed closures and hardware. Hybrid approaches let designers balance comfort and drape with structural or sculptural effects.

Materials

Nylon: Common in SLS; strong, wear-resistant, and with the right geometry, surprisingly flexible for garments. Nylon powders are a workhorse for articulated pieces.

TPU: Offers stretch and comfort; ideal for wearables that need elasticity.

Resins: Some resin chemistries balance detail with softness for decorative wearable parts.

Composite filaments & coatings: Metallic finishes, soft coatings, and surface treatments extend the visual language of printed fashion.

Sustainability in Fashion Industry

The Sustainability Promise

3D printing offers real sustainability advantages where it replaces wasteful mass production models. On-demand manufacturing, local production, and mass-customization that reduce unsold inventory. For designers doing made-to-order pieces, 3D printing workflows can dramatically cut overproduction. Designers like Danit Peleg have championed on-demand and circular-design mindsets as part of the technology’s promise.

The Caveats

However, the sustainability story isn’t universally rosy. Common issues include:

• Material recyclability: Not all 3D printing materials are easy to recycle; some resins are toxic or require special handling, and mixed-material garments complicate recycling streams.

• Energy intensity: Certain printing processes can be energy-intensive compared with low-energy textile knitting.

• Post-processing waste: Supports, powder sieving, and finishing steps produce additional waste streams that need management.

Progress and Mitigation

The industry is responding. Recyclable nylons, industrial recycling loops for powder, take-back programs, and improved material chemistries are all emerging. Some brands and labs report closed-loop recycling pilots for PA powders; others prioritize reducing material usage via optimized lattice geometry. Continued R&D on biobased and fully recyclable elastomers remains an active and necessary area of work.

COMMENTS

- Be the first to share your thoughts!