What is Peening

Peening is a surface treatment that plastically deforms a thin surface layer of a metal so that compressive residual stresses remain once elastic recovery finishes. Because cracks initiate and grow under tensile stress, replacing tensile near-surface stresses with compression significantly raises the stress required for crack nucleation and slows crack propagation. The net result is improved fatigue life, better resistance to stress-corrosion cracking, and often improved durability of welded or machined features.

Key metrics for any peening treatment are:

• Depth of compressive zone: how far below the surface compressive stresses extend.

• Magnitude of compressive stress: how compressive the near-surface can be stressed.

• Surface condition: roughness and cold work.

• Repeatability: how consistently you can produce the desired profile.

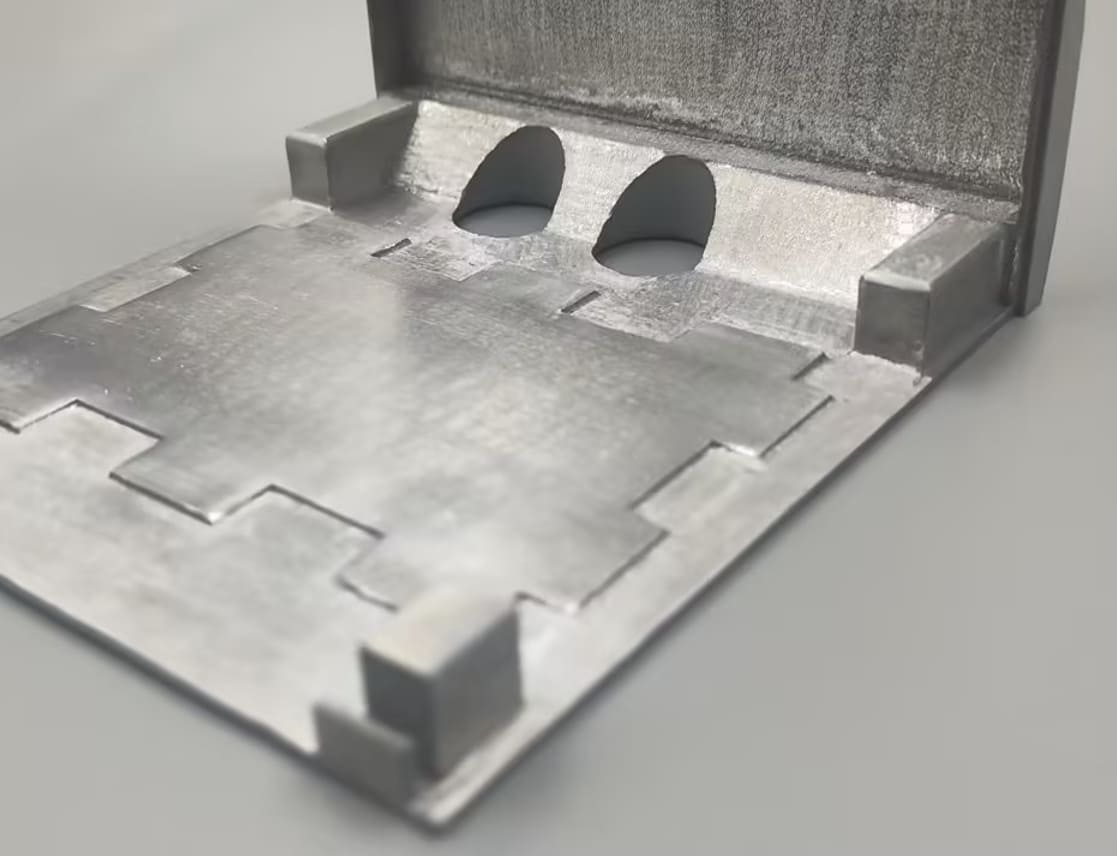

Image Source: Trulife Engineered Solutions

How Does Shot Peeing Works

Shot peening is a mechanical, abrasive-free process in which small spherical media, such as steel shot, ceramic beads, or glass beads, are accelerated and impacted against the part surface. Each shot particle creates a tiny indentation and plastically deforms the surface locally. When many dimples overlap with controlled coverage, a uniform layer of cold-worked, compressively stressed material builds up.

Key Features

• Surface becomes rougher and is cold-worked.

• The compressive layer is generally shallow compared with laser peening.

• Good for high-volume and complex shapes; easily applied to cavities, concave shapes, and small features.

• Equipment is relatively simple and widely available; operators can achieve high throughput.

How Does Laser Peeing Works

Laser peening uses focused, high-energy laser pulses to produce a short-duration, high-pressure plasma on the part surface. The plasma expands so quickly that it launches a shock wave into the metal. When the surface is confined, the shock is stronger and longer lasting, driving compressive stresses deeper into the material than mechanical impacts can.

Key Features

• Produces deeper compressive layers and can achieve high compressive magnitudes near the surface.

• Leaves minimal surface roughening. Surface integrity is often superior compared with shot peening.

• Highly controllable and repeatable for localized treatment.

• Equipment is complex and capital-intensive. The process is generally slower per unit area and is often used for high-value or critical components and repairs.

Performance Comparison

Depth and Magnitude

Laser peening typically creates deeper compressive profiles and can impart higher compressive magnitudes close to the surface. Depth advantage is why laser peening is frequently chosen for rotating aero-engine components, turbine blades, and critical weld toes.

Shot peening usually produces a shallower layer concentrated near the surface. For many parts, the depth is sufficient to obtain the desired fatigue improvement.

Surface Condition and Microstructure

Shot peening produces a characteristic dimpled, cold-worked surface and increases surface roughness. It can be beneficial for coatings adhesion, but may require additional finishing where tight surface tolerance or low friction is needed.

Laser peening preserves or improves surface finish and introduces less surface cold work while driving deeper compressive stress.

Effect on Fatigue and SCC

Both processes reduce crack initiation and slow early crack growth. Where failure initiates very close to the surface or where deep subsurface tensile stresses exist, laser peening’s deeper compressive layer usually gives superior life extension. For many commercial parts, shot peening provides excellent, cost-effective improvements.

Repeatability and Localized Treatment

Laser peening offers higher process control and repeatability in localized, critical zones.

Shot peening is excellent for blanket treatments and complicated shapes, but can be harder to tightly control on tight tolerances without masking.

Cost, Throughput, and Scalability

Capital and Operating Cost

Shot peening equipment is comparatively inexpensive; operating costs include media replenishment, maintenance of blast cabinets, and media recycling. It scales well, especially for high volumes.

Laser peening requires high-power lasers, beam delivery systems, and often automation and water confinement systems. Capital cost and maintenance are high. Operating costs include laser maintenance and consumables for any overlay materials.

Throughput

Shot peening is typically faster per unit area and well-suited to throughput-driven manufacturing.

Laser peening is typically slower, but because it can be targeted, the total cycle time for a part can be competitive when only small, critical areas need treatment.

When Each is Economical

Shot peening: high-volume parts with moderate fatigue demands, commodity automotive and industrial components.

Laser peening: high-value parts where deep compressive stresses or minimal surface alteration are critical.

Practical Considerations

Geometry and Accessibility

Shot peening can reach many complex shapes, but may have trouble uniformly peening very tight internal features without special tooling. Laser peening requires line-of-sight and precise fixturing but can be directed to small critical zones.

Dimensional Tolerances and Finishing

If your part requires smooth surfaces or tight dimensional control, laser peening’s low surface roughening is attractive. If roughness is acceptable or desired, shot peening is fine and cheaper.

Material Compatibility

Both are used on steels, nickel alloys, titanium, and many aluminum alloys. Be mindful of heat-treated or highly stressed parts.

Environmental and Safety

Shot peening generates used media and dust control requirements. Laser peening requires laser safety, shielding, and appropriate training.

Decision Checklist

|

Criteria |

Shot peening |

Laser peening |

Quick note |

|

Depth of compressive layer |

Shallow |

Deep |

Pick by how far compression must reach |

|

Compression strength |

Moderate |

High |

Laser usually gives stronger near-surface compression |

|

Surface finish |

Rougher |

Smooth |

Laser keeps surface cleaner |

|

Geometry |

Great for complex shapes |

Needs line-of-sight |

Shot is better for cavities; laser for exposed spots |

|

Production volume |

Best for high volume |

Better for low volume |

Shot is cheaper per part at scale |

|

Speed (per area) |

Fast |

Slower |

Laser is targeted, not blanket |

|

Dimensional control |

More change to surface |

Less distortion |

Laser is more predictable |

|

Typical materials |

Steel, Al, Ti, etc. |

Same |

Always qualify for specific alloy |

|

Inspection methods |

Almen, XRD, hole-drill |

XRD, ultrasonic, hole-drill |

Ensure you can measure what you need |

|

Typical use case |

Springs, gears, mass production |

Turbine blades, repairs, critical components |

Decide by value and required performance |

COMMENTS

- Be the first to share your thoughts!