The following article is provided for reference only and is not a substitute for professional advice. If an accident, exposure, fire, spill, or any other emergency occurs, stop operations immediately only if it is safe to do so, isolate the area to prevent further harm, and follow your site’s emergency procedures. If there is any threat to life, health, or property, call local emergency services without delay. Notify your designated safety officer or a qualified health-and-safety professional as soon as possible, and have the relevant Safety Data Sheets (SDS) or product information ready to share with responders.

Hazards You Need to Know

Airborne Emissions (UFPs and VOCs)

Heating plastics and curing resins can release ultrafine particles (UFPs) and volatile organic compounds (VOCs). These can irritate the eyes, nose and lungs and may be a long-term health concern in poorly ventilated spaces.

Powder Hazards

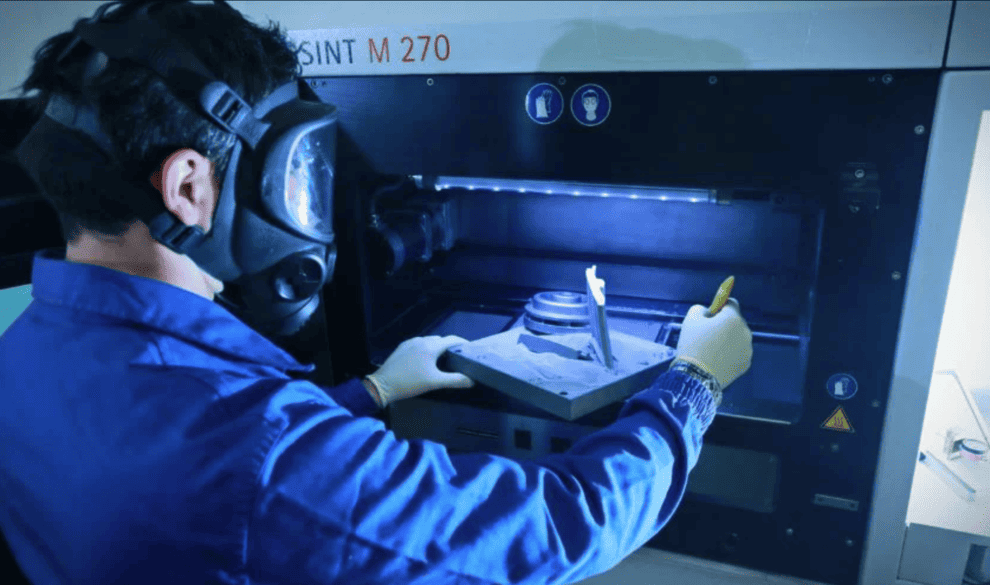

Fine powders used in SLS, MJF and metal PBF can be inhaled, contaminate skin, and create combustible dust/explosion risks. Metal powders are especially hazardous as they can ignite and burn at high temperatures.

Chemical Hazards

Uncured resins, solvents, and finishing chemicals may cause skin sensitization, chemical burns, or harmful vapors. Safety Data Sheets (SDS) give the definitive hazards for each chemical.

Thermal and Mechanical Risks

Hot nozzles, heated beds, UV cure lamps, and moving printer parts can cause burns, pinch injuries or cuts during build removal and maintenance.

Fire and Electrical Risks

Faulty wiring, poor ventilation around heat-generating equipment, or flammable dust/chemicals increase fire risk.

Ergonomics, Noise and Housekeeping

Repetitive motions, awkward postures when removing parts, loud post-processing equipment, and cluttered workspaces all contribute to injuries.

Image Source: 3DNatives

How to Control and Reduce Risks

Engineering Controls

• Enclosures and interlocks. Use closed build chambers and interlocks that cut power when doors open, which reduces UFP escape and prevents contact with hot surfaces.

• Local exhaust ventilation. Capture hoods or down-draft benches near sanding, vapor smoothing, or solvent baths remove dust and vapors at the source.

• Filtration. Combine HEPA filtration for particulates with activated-carbon filtration for VOCs. Ensure filters are rated and changed on a schedule; treat spent filters as contaminated waste.

• Sealed powder handling. For powder processes, use gloveboxes, sealed transfer containers, or dedicated powder stations with HEPA downflow to minimize airborne powder.

• Grounding & static control. For fine powders, install grounding straps, conductive flooring or anti-static measures to reduce ignition risk.

Administrative Controls and Safe Procedures

• SDS review and written SOPs. Maintain accessible SDS files and create Standard Operating Procedures for each material and process step (printing, powder handling, post-processing).

• Scheduling and zoning. Run high-emission jobs when fewer people are present, and separate powder/metal areas from general workspaces.

• Maintenance and logs. Keep filter-change logs, checklists for enclosure seals, and scheduled electrical and ventilation inspections.

• Training and competency sign-off. Require operators to complete training and competency checks before using hazardous processes, especially metal powder and solvent work.

Personal Protective Equipment

• Respiratory protection. Use respirators when engineering controls don’t reduce exposures sufficiently. For particulates, P100 cartridges or PAPR systems provide stronger protection than disposable masks; for VOCs, use cartridges rated for organic vapors. Respirator selection must be based on hazard assessment and include fit testing.

• Skin protection. Nitrile gloves for resins and solvents; thicker, cut-resistant gloves when handling hot or sharp parts. Change gloves frequently and avoid touching your skin.

• Eye protection and face shields. Use goggles for splashes and face shields for chemical baths or blasting operations.

• Other PPE. Flame-resistant clothing for metal-powder work; hearing protection for noisy post-processing equipment.

Waste Management and Disposal

Proper segregation and disposal protect people and the environment.

• Segregate waste streams. Keep uncured resins, contaminated solvents, solvent wipes, polymer/metal powders, electronic waste, and general trash in clearly labeled containers.

• Containment. Use sealed containers for contaminated powders and liquid wastes. Rags and wipes saturated with solvents should go into self-closing metal bins to prevent spontaneous combustion.

• Label and store properly. Mark hazardous waste with contents and date. Store waste in secondary containment until disposal.

• Follow local rules. Hazardous-waste regulations vary. Follow local, regional and national rules for disposal. Use licensed hazardous waste contractors for resins, solvents, and metal powders.

• Recycling where possible. Some post-processing plastics and support materials can be recycled through specialized programs. Check with material suppliers and waste vendors.

Emergency Response

Be prepared and practice responses before an incident happens.

• Fire response. Provide appropriate extinguishers: ABC for general fires, CO2 for electrical, and Class D for metal fires (never use water on metal powder fires). Train staff in their correct use.

• Spill response. Keep spill kits for solvents and powders. For powder spills, avoid sweeping; use HEPA-vacuuming or wet methods to suppress dust.

• Chemical exposure. Install eyewash stations and safety showers where resins or solvents are used. Train operators on first-aid for skin/eye exposure and have emergency contact and SDS info posted.

• Inhalation/over-exposure. Remove the affected person to fresh air and seek medical attention. For serious exposures, call emergency services and provide SDS details.

• Incident reporting and drills. Log incidents and near misses, perform root-cause reviews, and run regular emergency drills so responses are practiced and quick.

Daily Operator Checklist

√ Review job SOP & material SDS for today’s run.

√ Confirm printer enclosure closed and interlocks enabled.

√ Verify local exhaustventilation is operating.

√ Check filter status date (if due, flag).

√ Wear required PPE: respirator (if required), gloves, eye protection.

√ Ensure work area is clear of clutter; no food/drink in workspace.

√ Powder work: confirm sealed transfer containers and grounding straps are in place.

√ Resin work: confirm wash station lid closed and curing cabinet ready.

√ Solvent baths: confirm secondary containment and ventilation.

√ Fire extinguisher accessible and not blocked.

√ Eyewash/showers access checked (clear path).

√ Tools/fixtures checked for damage; sharp edges guarded.

√ Post-print: plan safe part removal (cooling time, tools, PPE).

√ End of day: secure consumables, label/store waste correctly, log any incidents.

COMMENTS

- Be the first to share your thoughts!