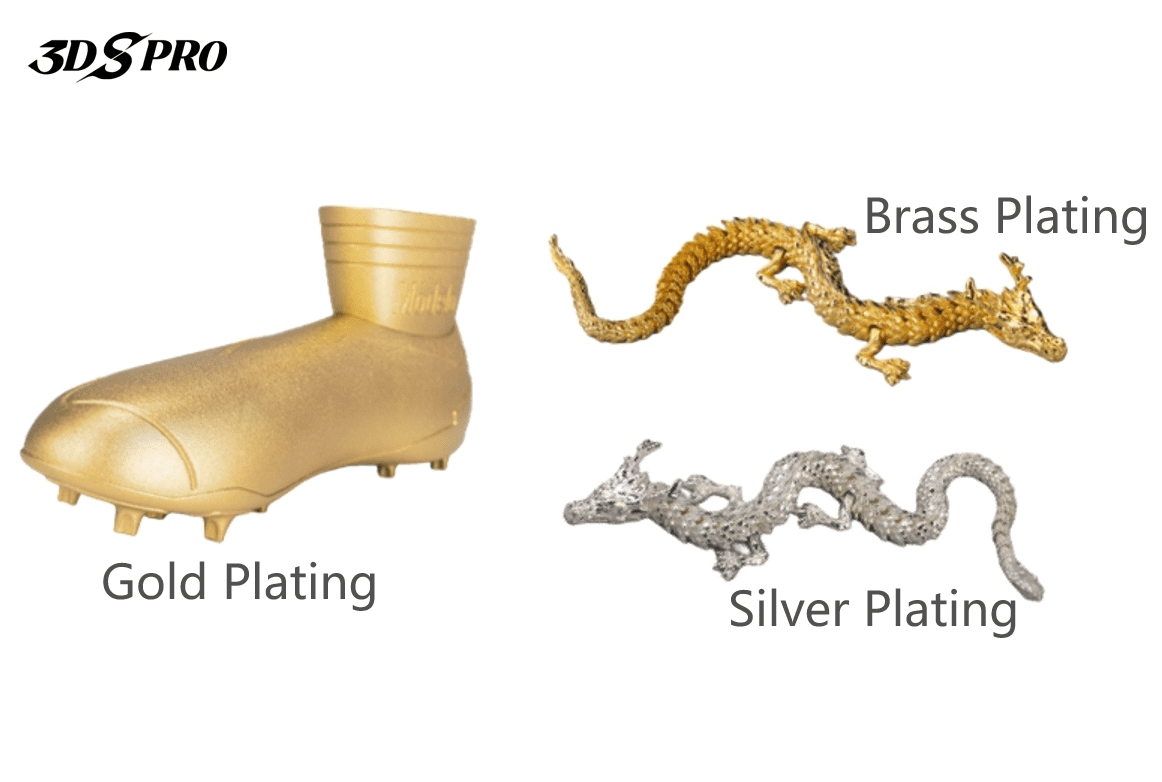

3DSPRO’s 3D Plus™ Solutions offer professional post-processing services and convenient online ordering support. One of our most popular post-processing options is electroplating, which enhances the durability and appearance of 3D printed parts. Today, we’re excited to share some insights into electroplating and its three types: gold plating, silver plating, and brass plating. Let’s get started!

What is electroplating?

Electroplating is a process that uses an electric current to deposit a thin layer of metal onto the surface of another material, enhancing its appearance, durability, and corrosion resistance. The 3D prints to be plated (the cathode) and a piece of the plating metal (the anode) are immersed in an electrolyte solution containing metal ions. When an electric current is applied, metal ions from the electrolyte are reduced and deposited onto the cathode, forming a thin metal coating. Electroplating is widely used in various industries to improve wear resistance, reduce friction, enhance conductivity, and provide decorative finishes.

How does metal plating work?

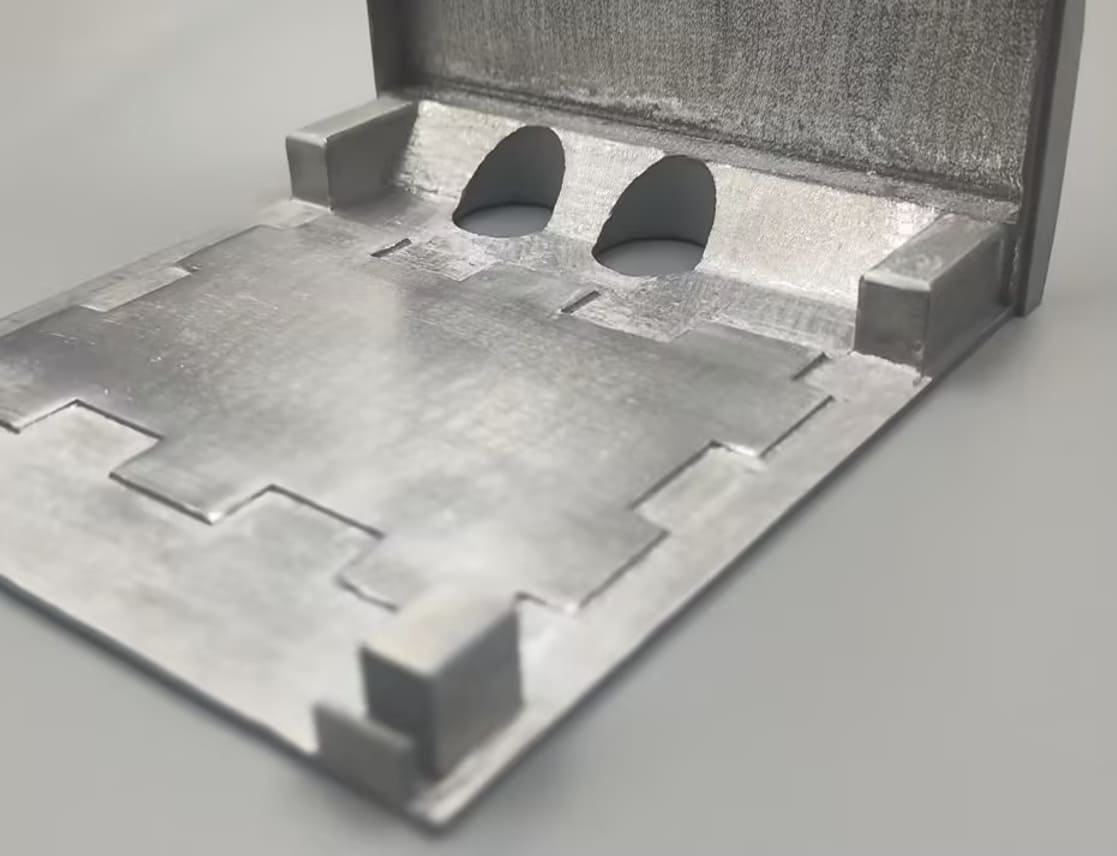

1. Preparation: Clean the object to be plated (the cathode) thoroughly to remove any dirt, grease, or oxidation. Use sandblasting/bead blasting/polishing to ensure a smooth surface finish.

2. Setup: Immerse the cathode and the anode (the metal to be plated) in an electrolyte solution containing metal ions.

3. Electric Current: Connect the cathode to the negative terminal and the anode to the positive terminal of a power supply. When the electric current is applied, metal ions from the anode dissolve into the electrolyte solution.

4. Deposition: The metal ions in the electrolyte are attracted to the cathode and deposit on its surface, forming a thin metal layer.

5. Duration: The thickness of the plating depends on the duration of the current flow. Longer exposure results in a thicker coating.

6. Post-Treatment: After plating, the 3D prints may undergo additional treatments, such as drying and applying protective coatings to enhance durability and appearance.

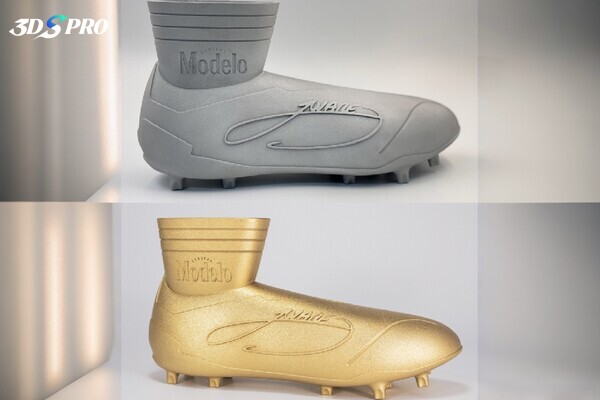

Gold Plating

Gold plating is a process that deposits a thin layer of gold onto the surface of another metal, usually through electroplating. It provides a luxurious and distinguished look, making 3D prints look more valuable and attractive. Gold plating enhances the appearance, durability and corrosion resistance of 3D printed parts and is widely used in jewelry, electronics and even space applications.

Image Provided by Our Partner: Bennett Awards

Types of Gold Plating

1. Hard gold plating: It applies a thick layer of gold to make it durable and wear-resistant. It is often used in electronic and electrical applications.

2. Soft gold plating: It focuses on the purity and softness of the gold layer, making it ideal for applications that require superior conductivity, such as semiconductor devices and connectors.

3. Double gold plating: It plates both hard and soft gold layers on the substrate, combining the advantages of both types for enhanced performance.

4. Immersion gold plating: In this process, the item is immersed in a solution containing dissolved gold ions. Through a chemical reaction, the gold ions bind to the surface, providing a durable and uniform coating.

5. Selective plating: It involves plating gold to specific areas of an object to create a unique pattern or design. It is often used for decorative purposes and complex electronic components.

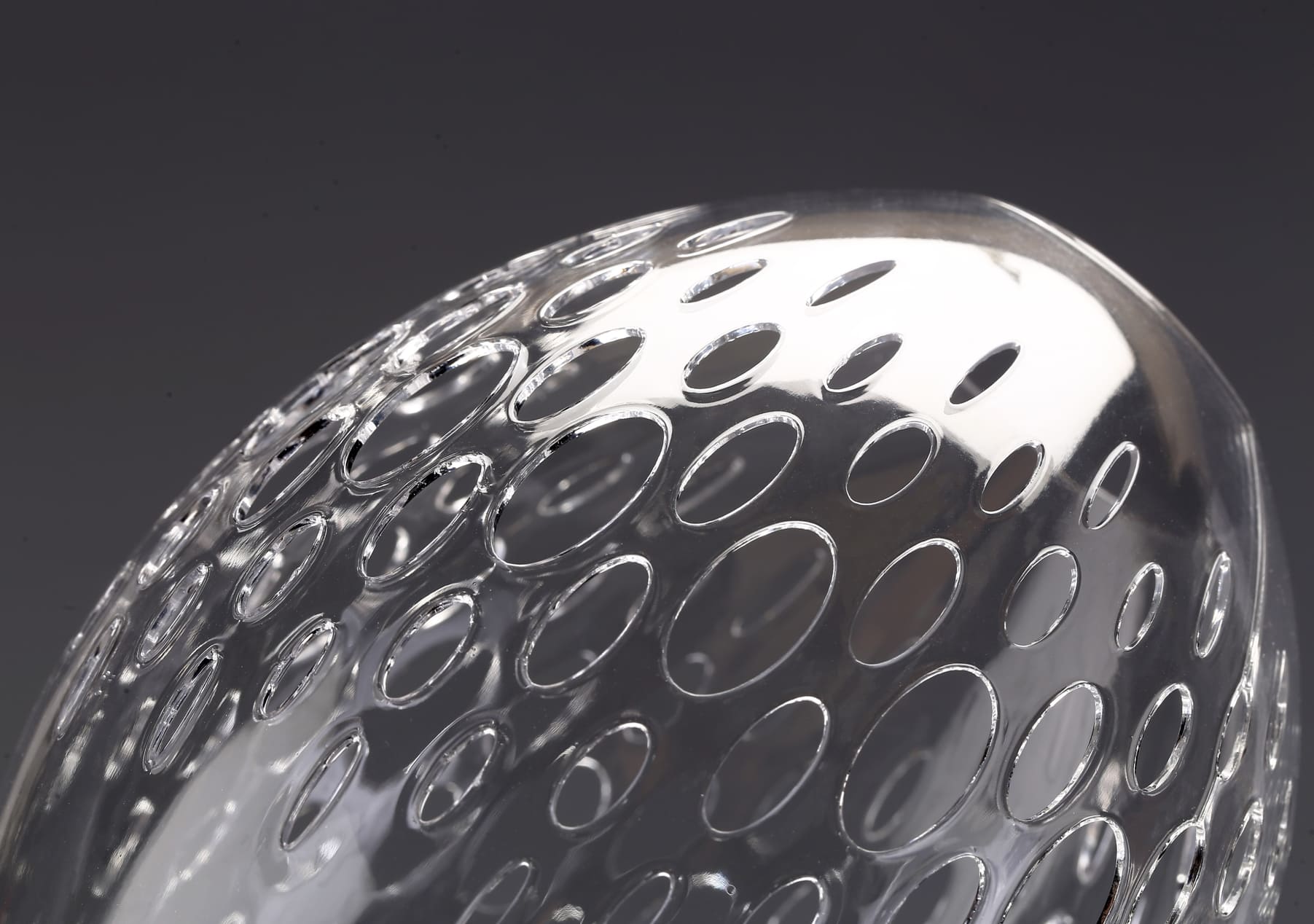

Silver Plating

Silver plating involves depositing a thin layer of silver onto another metal’s surface, typically through electroplating, to enhance appearance, durability, and electrical conductivity. It is a cost-effective technique that provides excellent conductivity, corrosion resistance, and a bright, attractive finish. Silver’s natural antibacterial properties make it ideal for medical devices, while its high conductivity benefits electronic components like connectors and circuit boards.

Additionally, silver plating is used in jewelry for a luxurious look, in aerospace for durability under extreme conditions, and in automotive parts for enhanced appearance and protection against corrosion. Its versatility extends to various industrial applications, including bearings and gears, to reduce friction and wear.

Silver Plated Articulated Dragon

Types of Silver Plating

1. Bright Silver Plating: Produces a shiny, reflective surface and is often used for decorative purposes and jewelry.

2. Matte Silver Plating: Produces a non-reflective, dull surface and is suitable for applications where glare needs to be minimized.

3. Semi-Bright Silver Plating: Provides a balance between bright and matte surfaces, providing moderate reflectivity.

4. Rack Plating: Used for larger or more delicate items that need to be individually mounted on racks during the plating process.

5. Barrel Plating: Used for smaller, bulk items that can be tumbled together in a barrel during the plating process.

6. Continuous Plating: Used for long strips or wires that are continuously passed through the plating solution.

Brass Plating

Brass plating involves depositing a thin layer of brass onto another metal’s surface, typically through electroplating, to enhance appearance, durability, and corrosion resistance. It provides a warm, golden finish that resembles solid brass, making it popular for decorative purposes. Brass plating is widely used in hardware items like door handles and hinges, lighting fixtures, fasteners, musical instruments, and automotive parts. It can be applied to various base metals, including steel, zinc, and copper, making it suitable for a wide range of applications. The brass layer also offers a protective barrier against corrosion, extending the lifespan of the plated 3D prints.

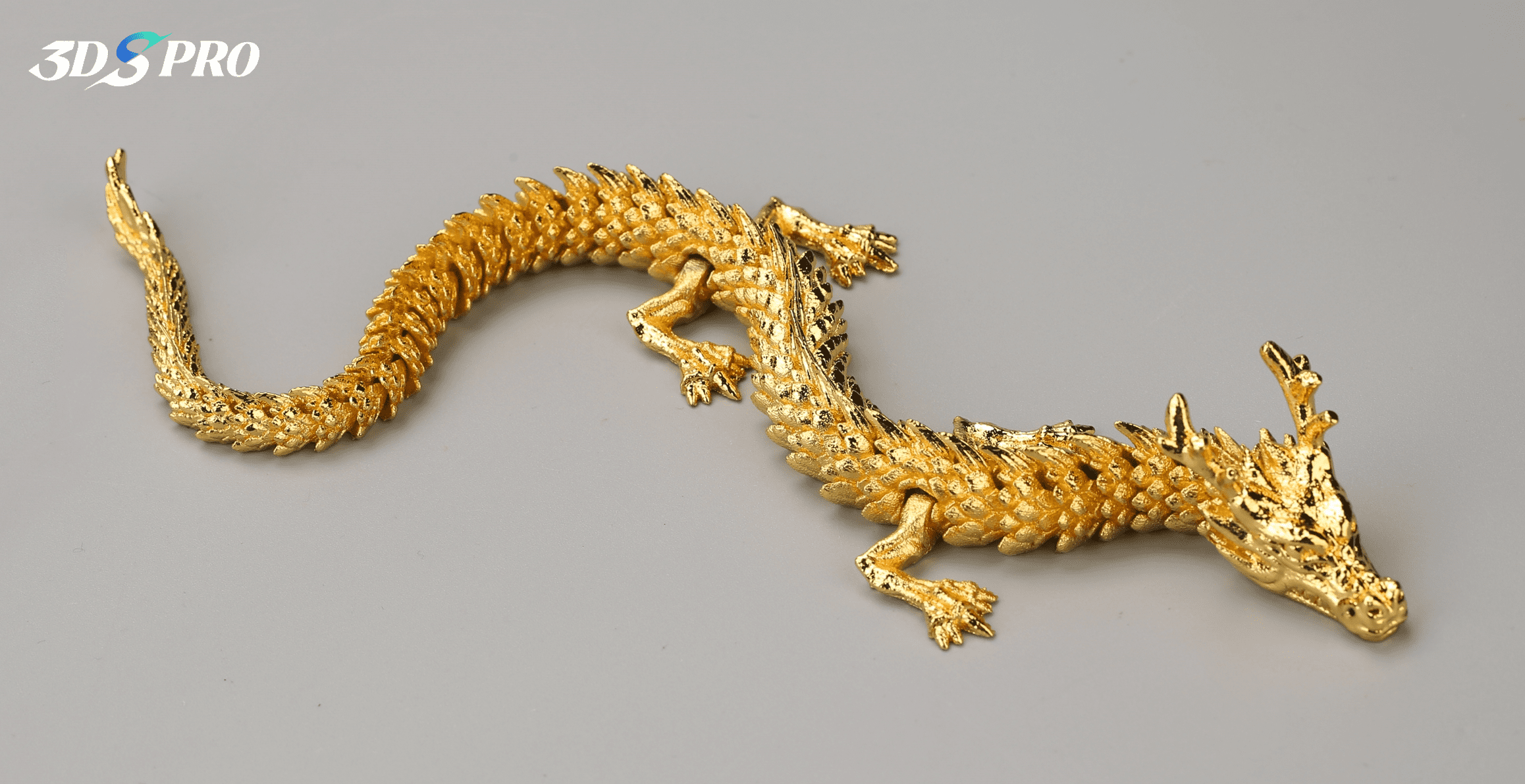

Brass Plated Articulated Dragon

The types of brass plating include bright brass plating, matte brass plating, rack plating, barrel plating, continuous plating, and antique brass plating.

Antique brass plating is a process that treats layers of brass to give it an aged, vintage look. This finish is achieved by chemically treating the brass to darken it to a medium brown color while retaining the golden undertones. The result is a duller, less shiny finish than polished brass, giving the item a classic, antique look. Antique brass plating is often used on hardware, decorative items, and fixtures to provide a timeless, elegant aesthetic.

COMMENTS

- Be the first to share your thoughts!