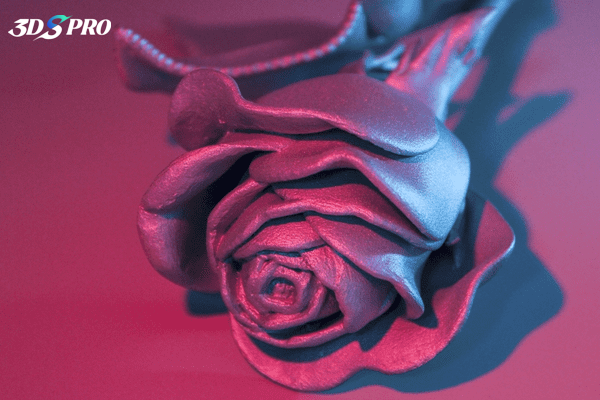

We Used Bead Blasting to Handle the Surface Finish of A 3D Printed Rose

Floristry, a professional and creative floral design company, recently worked with us to create a stunning 3D printed rose using advanced metal 3D printing technology. The rose was created using the Selective Laser Melting (SLM) process, which uses a high-energy laser to melt fine metal powder layer by layer, building the rose from scratch. This method is great for achieving intricate details and geometric shapes and is perfect for replicating the delicate petals of a rose.

To enhance the final appearance, we used bead blasting (glass bead) as a post-processing method. This technique gives the 3D printed roses a natural sheen and shiny surface finish. Furthermore, this innovative approach is environmentally friendly and demonstrates our commitment to sustainable development.

What is bead blasting?

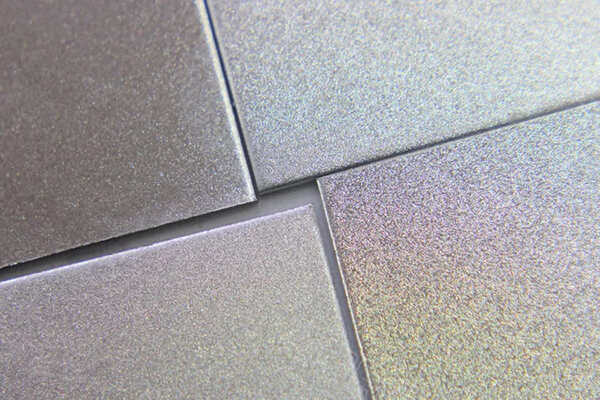

Bead blasting is a surface finishing technique that involves propelling tiny spherical beads, typically made from glass, ceramic, or metal, at high speed towards a material to clean, polish, or finish it. This method effectively removes rust, paint, and other contaminants without damaging the underlying material, resulting in a smooth, uniform finish. It also prepares surfaces for further treatments like painting or coating by creating a texture that enhances adhesion.

Widely used in industries such as automotive, aerospace, and medicine, bead blasting is valued for its ability to achieve a consistent, matte finish and improve the overall appearance and durability of the treated surfaces.

Types of Beads

● Glass Beads: Made from soda-lime glass, these beads are ideal for achieving a smooth, satin finish without damaging the underlying material.

● Ceramic Beads: Made from zirconium oxide, these beads are tougher and more durable, suitable for more aggressive cleaning and achieving a smoother finish.

● Steel Beads: Tiny, spherical steel balls used for heavy-duty cleaning, effective against rust and scaling.

Bead Blasting Advantages

● Effective Cleaning: Removes contaminants, rust, and surface imperfections.

● Smooth Finish: Leaves a clean, uniform, and smooth surface.

● Versatility: Compatible with a wide range of materials.

● Eco-Friendly: Beads are recyclable, making the process environmentally friendly.

● Enhanced Appearance: Achieves a consistent, matte finish that improves the material’s look.

● Improved Durability: Reduces surface stress and can enhance the strength and durability of the treated materials.

● Safe and Efficient: A safe method for achieving high-quality surface finishes. Prepares surfaces for further treatments like painting or coating by creating a texture that enhances adhesion.

How to bead blasting 3D printed parts?

Preparation:

● Clean the Part: Ensure the 3D printed part is free from dust, debris, and any loose particles.

● Masking: If there are areas that should not be blasted, mask them off with tape or a protective covering.

Setup:

● Bead Blasting Cabinet: Place the part inside a bead blasting cabinet to contain the beads and dust.

● Select Beads: Choose the appropriate type of beads (e.g., glass, ceramic, or metal) based on the desired finish and material of the part.

Blasting Process:

● Adjust Pressure: Set the blasting pressure according to the material and the level of finish required.

● Blasting: Use a bead blaster gun to direct the beads at the part’s surface. Move the gun in a consistent, sweeping motion to ensure an even finish.

Post-Blasting:

● Inspect the Part: Check the part for uniformity and ensure all desired areas have been treated.

● Clean Up: Remove any remaining beads and dust from the part.

Additional Step:

● Additional Finishing: If needed, perform any additional finishing steps, such as polishing or coating, to achieve the final desired appearance.

Bead Blasting at 3DSPRO

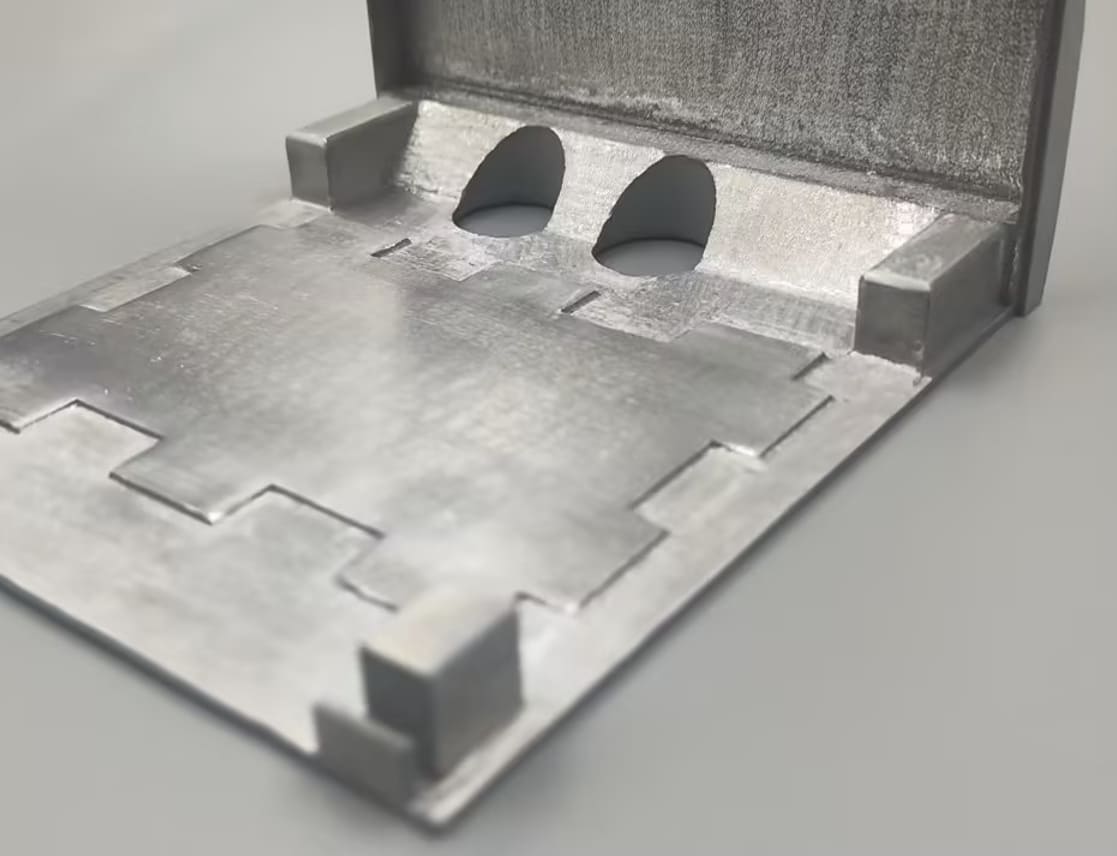

At 3DSPRO, we offer a professional bead blasting service for 3D printed metal parts produced at our facility. Our bead blasting process uses fine glass beads propelled at high speed to clean, polish, and finish your 3D printed metal parts. Glass bead blasting effectively removes surface imperfections, resulting in a smooth, uniform, and aesthetically pleasing finish.

It is ideal for enhancing the appearance and durability of intricate metal parts, making them ready for further treatments or immediate use. Trust 3DSPRO to deliver high-quality, eco-friendly surface finishing solutions that meet your specific needs. Check out the cost of metal 3D printing and bead blasting for your projects HERE.

What customers are saying about 3DSPRO bead blasted 3D printed parts?

"The finish is smooth and beautiful, enhancing both the appearance and functionality of the parts."

"I was impressed by the intricate details that were preserved during the bead blasting process. 3DSPRO's attention to detail is unmatched, making my designs look even better than I imagined."

"Reliable and efficient. My parts were finished quickly without compromising on quality. I highly recommend their services for anyone needing top-notch post-processing."

"My parts now have a robust finish that can withstand more wear and tear."

"The team at 3DSPRO was incredibly helpful and responsive. They guided me through the entire process and ensured my parts were finished to perfection."

"I've used 3DSPRO's bead blasting service multiple times, and the results are always consistent. The parts come out looking great every single time."

"The pricing is very reasonable. It's great value for money, and I trust them to complete the rest of my projects."

COMMENTS

- Be the first to share your thoughts!