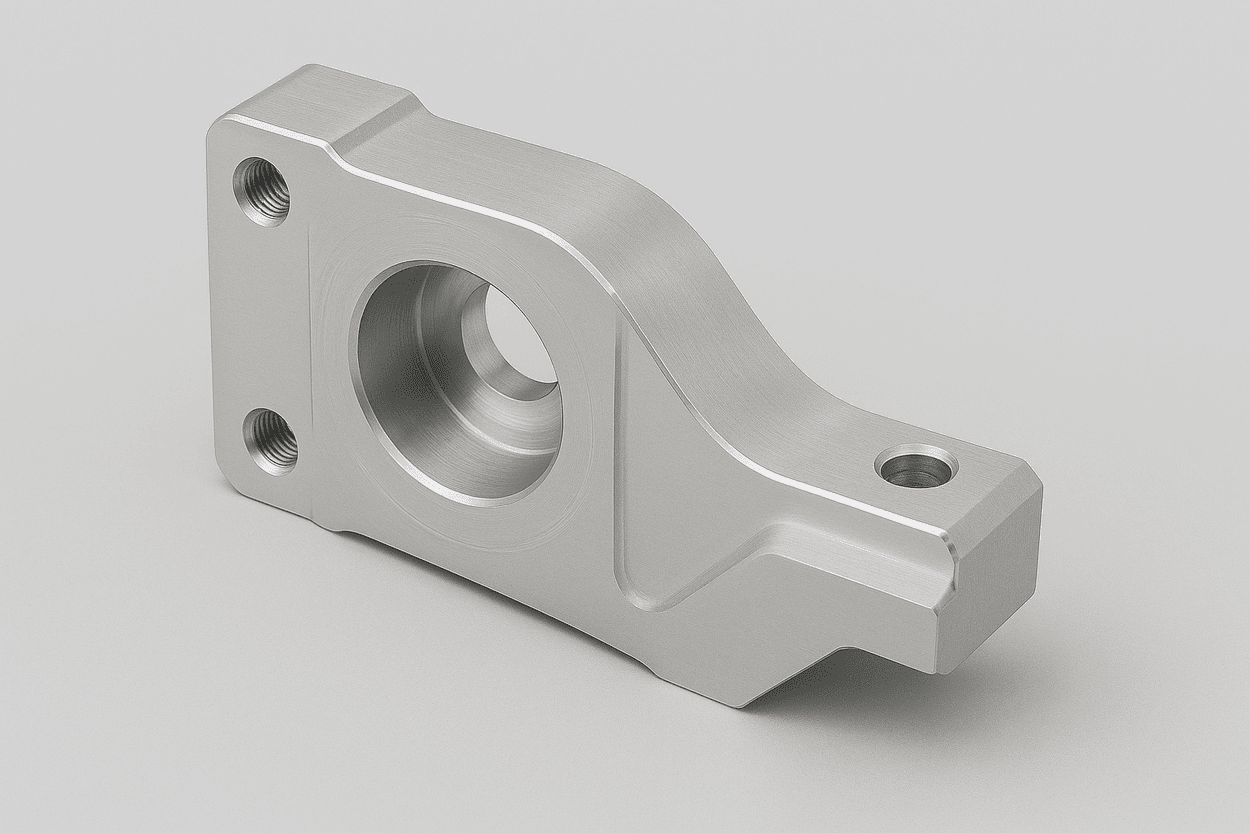

Computer Numerical Control (CNC) machining remains one of the most important and versatile manufacturing technologies in the world today. From aerospace brackets to medical implants to smartphone housings, CNC machining enables the creation of precise, durable, and highly repeatable parts across nearly every industry. Although additive manufacturing and advanced molding technologies continue to evolve, CNC machining still stands as the backbone of modern production thanks to its accuracy, material compatibility, and reliability.

What is CNC Machining?

CNC machining is a computer‑controlled subtractive manufacturing process where machines remove material from a solid block (called a workpiece) to create a final part. Instead of manual handwheels and levers, CNC machines follow precise digital instructions known as G‑code, allowing them to cut, drill, mill, turn, and shape materials with exceptional accuracy.

Key Features of CNC Machining

• Subtractive: material is removed to create the final geometry

• Automated: machines follow programmed toolpaths

• Highly accurate: tolerances can reach ±0.005 mm

• Versatile: works with metals, plastics, composites, and more

• Scalable: suitable for prototypes and full‑scale production

How CNC Machining Works?

Step 1: CAD Modeling

Every CNC project begins with a 3D CAD model. This digital blueprint defines the geometry, dimensions, tolerances, and features of the part.

Step 2: CAM Programming

The CAD model is imported into CAM (Computer‑Aided Manufacturing) software, which generates toolpaths, cutting strategies, speeds and feeds, and machine instructions (G‑code).

Step 3: Machine Setup

• A machinist prepares the CNC machine by:

• Securing the workpiece

• Installing cutting tools

• Setting zero points

• Loading the G‑code program

Step 4: Machining Execution

The CNC machine executes the programmed toolpaths. Depending on the machine type, this may involve milling, turning, drilling, boring, tapping, and EDM cutting.

Step 5: Inspection & Quality Control

Finished parts undergo dimensional checks using calipers and micrometers, CMM (Coordinate Measuring Machines), and surface roughness testers.

Types of CNC Machines

CNC machining is not a single technology but a family of digitally controlled manufacturing systems, each designed to perform specific cutting, shaping, or finishing operations. Understanding the different machine types helps designers choose the right process for their geometry, tolerances, and material needs. Below is a deeper, more structured overview of the major CNC machine categories, how they work, and when to use them.

1. CNC Milling Machines

CNC milling is the most widely used CNC process. Milling machines use rotating cutting tools to remove material from a stationary or moving workpiece.

Common Configurations

3‑Axis Mills

Move along X, Y, and Z. Ideal for prismatic parts, pockets, slots, and simple contours.

4‑Axis Mills

Add rotation around the X or Y axis. Useful for machining cylindrical features, engraving, and reducing setups.

5‑Axis Mills

Allow simultaneous movement across five axes. Essential for complex surfaces, undercuts, turbine blades, medical implants, and aerospace components.

When to Choose Milling

• Parts with flat surfaces, pockets, channels, or angled features

• High‑precision components

• Complex geometries requiring multi‑axis movement

• Prototypes and production parts in metals or plastics

2. CNC Lathes & Turning Centers

CNC turning machines rotate the workpiece while a stationary cutting tool removes material. They excel at producing round or cylindrical parts.

Types of Turning Machines

Standard CNC Lathes

For shafts, pins, bushings, and threaded components.

Turning Centers with Live Tooling

Combine turning with milling, drilling, and tapping in one setup.

Twin‑Spindle Turning Centers

Allow simultaneous machining on both ends of a part, improving throughput.

Key Advantages

• Extremely tight concentricity

• Fast cycle times

• Ideal for high‑volume production

• Best for: cylindrical parts, threads, tapers, grooves, and knurling, automotive, aerospace, and industrial components

3. Swiss‑Type CNC Machines

Swiss‑type lathes (also called Swiss screw machines) support the workpiece with a guide bushing, allowing very long, slender, or tiny parts to be machined with exceptional stability.

Key Features of Swiss Machining

• The cutting tool works very close to the guide bushing, minimizing deflection.

• Capable of tolerances in the micron range.

• Designed for continuous, high‑volume production.

Typical Applications

• Medical screws and implants

• Watch components

• Precision pins and fasteners

• Electronics connectors

4. CNC Routers

CNC routers resemble milling machines but are optimized for softer materials and high‑speed cutting.

Common Materials

• Wood

• Plastics

• Foam

• Composites

• Soft aluminum (in some cases)

Applications

• Furniture and cabinetry

• Signage

• Packaging

• Architectural models

• Large‑format prototyping

Routers typically have large work envelopes, making them ideal for sheet‑based materials.

5. CNC EDM (Electrical Discharge Machining)

EDM removes material using controlled electrical sparks rather than mechanical cutting. It is used exclusively for conductive materials.

Two Main Types

Wire EDM

Uses a thin wire to cut intricate profiles, sharp internal corners, and fine details.

Sinker EDM

Uses a shaped electrode to burn cavities into hardened metals.

Benefits of EDM

• Can cut hardened steels and superalloys

• Achieves extremely tight tolerances

• Produces geometries impossible with traditional cutting tools

Applications

• Injection mold tooling

• Die making

• Aerospace components

• Medical instruments

6. CNC Plasma, Laser, and Waterjet Cutters

These machines cut materials using energy‑based or fluid‑based processes rather than mechanical tools.

CNC Laser Cutting

• High precision

• Excellent for thin metals, plastics, and sheet materials

• Clean edges with minimal post‑processing

CNC Plasma Cutting

• Ideal for thicker metals

• Faster but less precise than laser cutting

CNC Waterjet Cutting

• Cuts virtually any material (metal, stone, glass, composites)

• No heat‑affected zone

• Perfect for thick or heat‑sensitive materials

These machines are often used for sheet metal fabrication, signage, architectural components, and industrial parts.

Materials for CNC Machining

Metals

Aluminum (6061, 7075)

• Lightweight

• Excellent machinability

• Ideal for aerospace, electronics, and automotive

Stainless Steel (304, 316, 17‑4PH)

• Corrosion‑resistant

• Strong and durable

• Used in medical, marine, and industrial applications

Steel Alloys

• High strength

• Good wear resistance

• Common in tooling and machinery

Brass & Copper

• Excellent electrical conductivity

• Used in electronics and plumbing

Titanium

• High strength‑to‑weight ratio

• Biocompatible

• Essential for aerospace and medical implants

Plastics

ABS

• Affordable and easy to machine

• Used for housings and prototypes

Nylon

• Strong and wear‑resistant

• Ideal for gears and bushings

POM (Delrin)

• Low friction

• Excellent dimensional stability

Polycarbonate

• Impact‑resistant

• Used for enclosures and optical components

PEEK

• High‑performance engineering plastic

• Withstands high temperatures and chemicals

Surface Finishes & Post Processing

As‑Machined

• Visible tool marks

• Standard finish for functional prototypes

• Smooth matte texture

• Ideal for cosmetic parts

Anodizing (Type II & Type III)

• Corrosion resistance

• Color options

• Hard anodizing for wear resistance

• Durable, colorful finish

• Great for consumer products

• High gloss

• Used for decorative or optical components

Heat Treatment

• Improves hardness and strength

• Common for steel and aluminum alloys

Passivation

• Enhances corrosion resistance of stainless steel

Plating (Nickel, Chrome, Zinc)

• Adds conductivity, corrosion resistance, or aesthetic appeal

Pros and Cons

Advantages

1. High Precision & Repeatability

CNC machines deliver extremely tight tolerances, making them ideal for aerospace, medical, and automotive applications.

2. Excellent Material Compatibility

Unlike 3D printing, CNC machining works with nearly all metals and engineering plastics.

3. Fast Turnaround

Once programmed, CNC machines can produce parts quickly and consistently.

4. Strong Mechanical Properties

Machined parts retain the full strength of the base material.

5. Scalable for Prototyping & Production

CNC machining is suitable for one‑off prototypes and large‑volume production.

Limitations

1. Higher Cost for Complex Geometries

Deep pockets, thin walls, and undercuts increase machining time and cost.

2. Material Waste

As a subtractive process, CNC machining generates chips and scrap.

3. Limited by Tool Access

Internal features and organic shapes may be difficult or impossible to machine.

4. Setup Time

Programming and fixturing require skilled labor.

Applications

1. Aerospace & Defense: Aerospace is one of the most demanding industries in the world, requiring extreme precision, lightweight materials, and flawless reliability. CNC machining is indispensable here because it can produce complex geometries in high‑strength metals like aluminum, titanium, and Inconel.

2. Automotive & Transportation: From prototyping to production, CNC machining supports nearly every stage of automotive development.

3. Medical & Dental Devices: Medical manufacturing requires exceptional precision, biocompatible materials, and flawless surface finishes, all strengths of CNC machining.

4. Consumer Electronics: Electronics rely heavily on CNC machining for both functional and cosmetic components.

5. Industrial Machinery & Equipment: CNC machining is the backbone of industrial equipment manufacturing, where durability and precision are essential.

6. Robotics & Automation: Robotics requires lightweight, strong, and highly precise CNC-machined components.

7. Energy & Power Generation: CNC machining supports both traditional and renewable energy sectors.

8. Tooling, Molds & Dies: CNC machining is the primary method for producing high‑precision tooling.

9. Architecture, Art & Creative Industries: Beyond engineering, CNC machining is widely used in creative fields.

When to Choose CNC Machining?

CNC machining is the right choice when your project requires:

1. Tight Tolerances: If your part needs precision within microns, CNC machining is unmatched.

2. High Strength & Durability: Machined parts maintain the full mechanical properties of the material.

3. Complex Geometries with Flat or Angular Features: Milling and turning excel at sharp edges, pockets, and prismatic shapes.

4. Low‑to‑Medium Volume Production: CNC machining is cost‑effective for quantities from 1 to several thousand.

5. High‑Quality Surface Finishes: Machining delivers smooth, consistent surfaces ideal for cosmetic parts.

6. Materials Not Suitable for 3D Printing: Metals like stainless steel, titanium, and copper machine beautifully.

7. Rapid Prototyping with Production‑Grade Quality: CNC prototypes behave exactly like final production parts.

COMMENTS

- Be the first to share your thoughts!