Computer Numerical Control (CNC) machines have become the backbone of manufacturing. Whether you’re producing aerospace components, medical implants, automotive parts, or custom prototypes, CNC technology delivers the precision, repeatability, and efficiency that today’s industries demand. At their core, CNC machines automate machining processes by using programmed instructions, allowing manufacturers to produce complex geometries that would be difficult, slow, or impossible to achieve manually.

But “CNC machine” is not a single category. It’s an umbrella term that covers a wide range of equipment, each designed for specific materials, geometries, tolerances, and production volumes. From mills and lathes to laser cutters and EDM systems, each machine type brings its own strengths and limitations.

CNC Machine Types at a Glance

|

CNC Machine Type |

Best Materials |

Typical Applications |

Key Advantages |

Limitations |

|

Milling Machine |

Metals, plastics |

Prototypes, molds, precision parts |

Versatile, high precision |

Slower for large volumes |

|

Lathe / Turning Center |

Metals, plastics |

Shafts, bushings, threaded parts |

Fast, ideal for cylindrical parts |

Limited to rotational geometries |

|

Swiss‑Type Lathe |

Metals |

Micro‑machining, medical, electronics |

Ultra‑precise, great for small parts |

Not ideal for large components |

|

Router |

Wood, plastics, composites |

Furniture, signage |

High speed, large work areas |

Not suitable for hard metals |

|

Laser Cutter |

Metals, plastics, wood |

Sheet metal, signage |

Clean edges, high accuracy |

Limited thickness for some materials |

|

Plasma Cutter |

Conductive metals |

Fabrication, automotive |

Fast cutting of thick metals |

Rougher edges than laser |

|

Waterjet |

Almost any material |

Stone, glass, metals |

No heat‑affected zone |

Slower and more expensive |

|

EDM |

Hardened metals |

Dies, molds, intricate shapes |

Machines very hard materials |

Slower than milling |

|

Grinding Machine |

Hardened metals |

Finishing, precision surfaces |

Extremely tight tolerances |

Limited to finishing |

|

Drilling/Boring/Tapping |

Metals, plastics |

Hole‑making |

Fast, consistent results |

Limited to specific operations |

|

Mill‑Turn Machine |

Metals |

Complex multi‑feature parts |

One‑and‑done machining |

Higher cost |

How CNC Machines Are Classified

Before diving into individual machine types, it helps to understand how CNC machines are generally categorized. Classification provides a framework for comparing capabilities and choosing the right equipment for a specific application.

1. By Motion Type (Number of Axes)

The number of axes determines how the cutting tool and workpiece move relative to each other.

• 2‑axis: Basic X and Y movement; suitable for simple profiles.

• 3‑axis: Adds Z movement; the most common configuration for milling and routing.

• 4‑axis: Adds rotation around one axis (A or B), enabling machining of cylindrical or angled features.

• 5‑axis: Adds rotation around two axes, allowing highly complex, multi‑sided machining with fewer setups.

More axes generally mean greater flexibility, higher precision, and the ability to machine complex geometries.

2. By Machining Method

CNC machines fall into several machining categories:

• Subtractive machining: Material is removed from a solid block (e.g., milling, turning, grinding).

• Thermal cutting: Material is cut using heat (e.g., laser, plasma).

• Abrasive cutting: Material is cut using high‑pressure water mixed with abrasive particles (e.g., waterjet).

• Electrical discharge machining (EDM): Material is removed using electrical sparks.

• Forming and shaping: Material is bent or formed using CNC‑controlled tools (e.g., press brakes).

Each method is suited to different materials, tolerances, and design requirements.

3. By Application

CNC machines are also classified by the industries or tasks they serve:

• Metalworking: Mills, lathes, EDM, grinders

• Woodworking: Routers, CO₂ lasers

• High‑precision micro‑machining: Swiss‑type lathes, EDM

• High‑volume production: Multi‑tasking machines, turning centers

• Fabrication and cutting: Plasma, waterjet, fiber laser

Major Types of CNC Machines

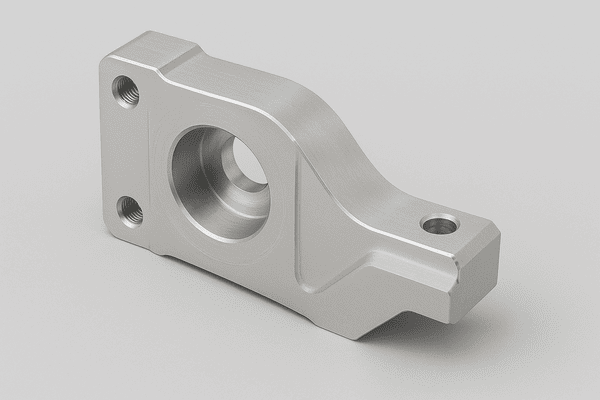

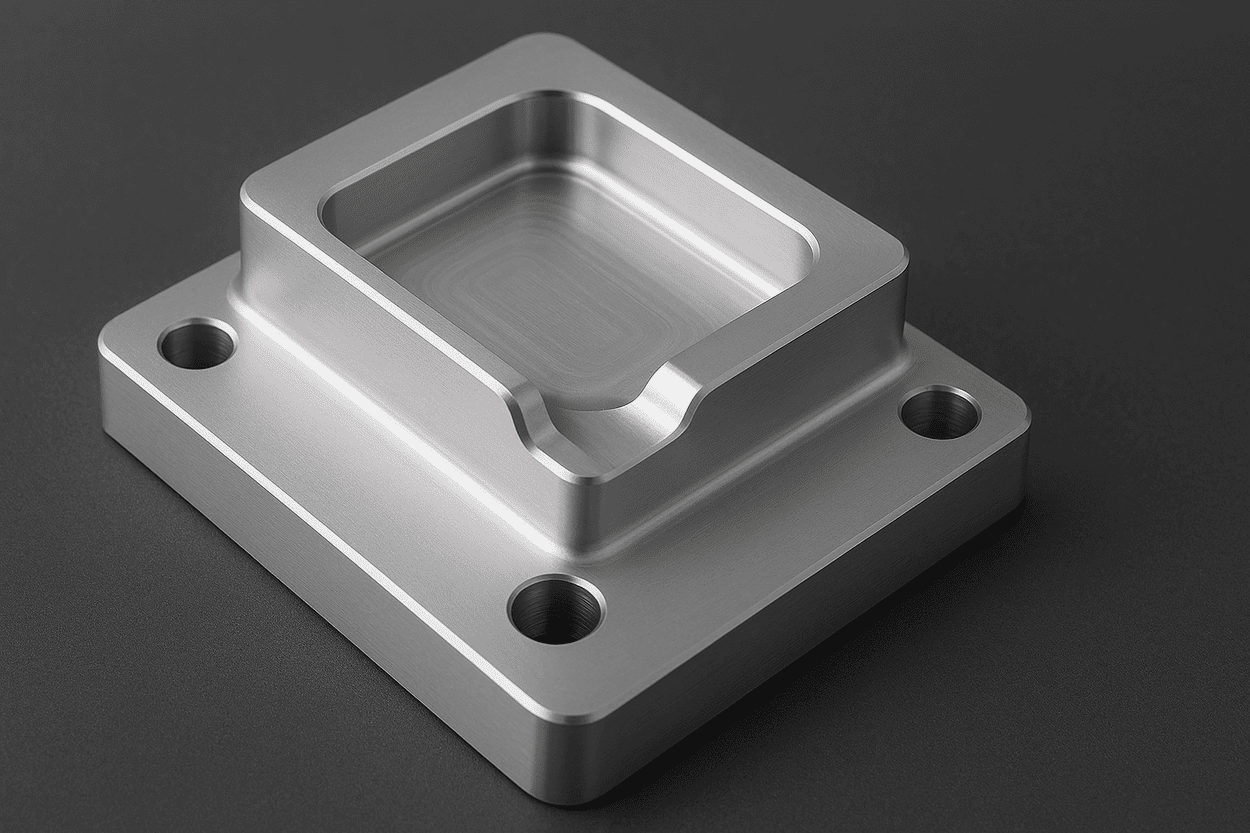

1. CNC Milling Machines

CNC milling machines use rotating cutting tools to remove material from a stationary workpiece. They are among the most versatile CNC machines and can produce flat surfaces, pockets, slots, contours, and complex 3D shapes.

CNC Milling Process

A spindle holds the cutting tool and moves along multiple axes while the workpiece remains fixed on the table. The machine follows programmed toolpaths to shape the material.

Machine Variants

• Vertical milling machines (VMCs): Spindle is vertical; ideal for general machining.

• Horizontal milling machines (HMCs): Spindle is horizontal; better for heavy material removal and chip evacuation.

• 5‑axis milling machines: Allow simultaneous movement along five axes for complex geometries.

Best for: Prototypes, molds, precision components, aerospace parts, and any part requiring tight tolerances.

2. CNC Lathes and Turning Centers

CNC lathes rotate the workpiece while a stationary cutting tool removes material. They excel at producing cylindrical or symmetrical parts.

CNC Turning Process

The workpiece spins at high speed while the cutting tool moves along the X and Z axes to shape the material.

Machine Variants

• 2‑axis lathes: Basic turning operations.

• Multi‑axis turning centers: Add Y‑axis, live tooling, and sub‑spindles for milling, drilling, and tapping.

• Twin‑spindle machines: Enable machining on both ends of a part without manual repositioning.

Best for: Shafts, bushings, pins, threaded components, and high‑volume production.

3. Swiss‑Type CNC Machines

Swiss‑type lathes are specialized turning machines designed for extremely small, precise parts.

Swiss-Type Process

The workpiece is supported by a guide bushing close to the cutting tool, minimizing deflection and enabling ultra‑tight tolerances.

Best for: Medical screws, watch components, electronics connectors, and micro‑machined parts.

4. CNC Routers

CNC routers are lightweight, high‑speed machines primarily used for softer materials.

CNC Router Process

A rotating spindle moves along X, Y, and Z axes to cut or engrave materials like wood, plastics, and composites.

Best for: Furniture making, signage, cabinetry, foam cutting, and prototyping.

5. CNC Laser Cutters

Laser cutters use a focused beam of light to cut or engrave materials with exceptional precision.

Types of Lasers

• CO₂ lasers: Best for wood, acrylic, plastics, leather, and thin metals.

• Fiber lasers: Best for metals, especially stainless steel, aluminum, and brass.

Best for: Sheet metal fabrication, signage, electronics enclosures, and decorative work.

6. CNC Plasma Cutters

Plasma cutters use an electrically ionized gas (plasma) to cut conductive metals.

CNC Plasma Cutter Process

A high‑temperature plasma arc melts the metal, and compressed air blows away the molten material.

Best for: Thick steel plates, structural components, automotive frames, and fabrication shops.

7. CNC Waterjet Cutters

Waterjet machines cut materials using a high‑pressure stream of water mixed with abrasive particles.

Best for: Stone, glass, ceramics, composites, metals, and laminated materials.

8. CNC Electrical Discharge Machines (EDM)

EDM machines remove material using electrical sparks between an electrode and the workpiece.

Machine Types

• Wire EDM: Uses a thin wire to cut intricate shapes.

• Sinker EDM: Uses a shaped electrode to create cavities.

Best for: Hardened steels, dies, molds, and extremely intricate geometries.

9. CNC Grinding Machines

Grinding machines use abrasive wheels to achieve extremely tight tolerances and fine surface finishes.

Machine Types

• Surface grinders

• Cylindrical grinders

• Centerless grinders

Best for: Finishing hardened parts, achieving mirror‑like surfaces, and meeting ultra‑tight dimensional tolerances.

10. CNC Drilling, Boring & Tapping Machines

These machines specialize in hole‑making operations. Often, these capabilities are integrated into machining centers, but standalone machines exist for mass production.

Best for: High‑volume production of components requiring consistent hole sizes, threads, or bores.

11. CNC Multi‑Tasking / Mill‑Turn Machines

Multi‑tasking machines combine milling and turning in a single platform.

Best for: Aerospace components, medical implants, and any part requiring both turning and milling features.

COMMENTS

- Be the first to share your thoughts!