Cheat Sheet for Choosing Between Metal 3D Printing and CNC Machining

|

Factor |

Metal 3D Printing |

CNC Machining |

|

Cost |

Good for small batch. |

Good for large production. |

|

Common Materials |

Stainless steel, tool steel, titanium, aluminum, and nickel-based alloys. |

Stainless steel, tool steel, titanium, aluminum, brass, copper, nickel, iron-nickel, and cobalt alloys. |

|

Speed |

Good for small batch. |

Faster for large production. |

|

Accuracy |

± 0.1 mm |

± 0.025 mm |

|

Volume |

Flexible for small volume. |

Good for high volume. |

|

Geometry |

Allow for complex geometry, such as intricate internal and lattice structures. |

Limited by tools. |

|

Mechanical Properties |

Excellent |

Excellent |

What is metal 3D printing?

Metal 3D printing, also known as metal additive manufacturing or metal additive printing, is a manufacturing process that involves building three-dimensional objects layer by layer using metal powder as the raw material. This process facilitates the fabrication of intricate metal components with complex geometries, which can be difficult or unfeasible to manufacture using conventional production techniques.

Metal 3D printing offers various advantages, such as design flexibility, minimized material wastage, and the capacity to fabricate lightweight yet robust parts. It is used across industries such as aerospace, automotive, healthcare, and engineering for prototyping, tooling, and end-use part production.

Types of Metal 3D Printing

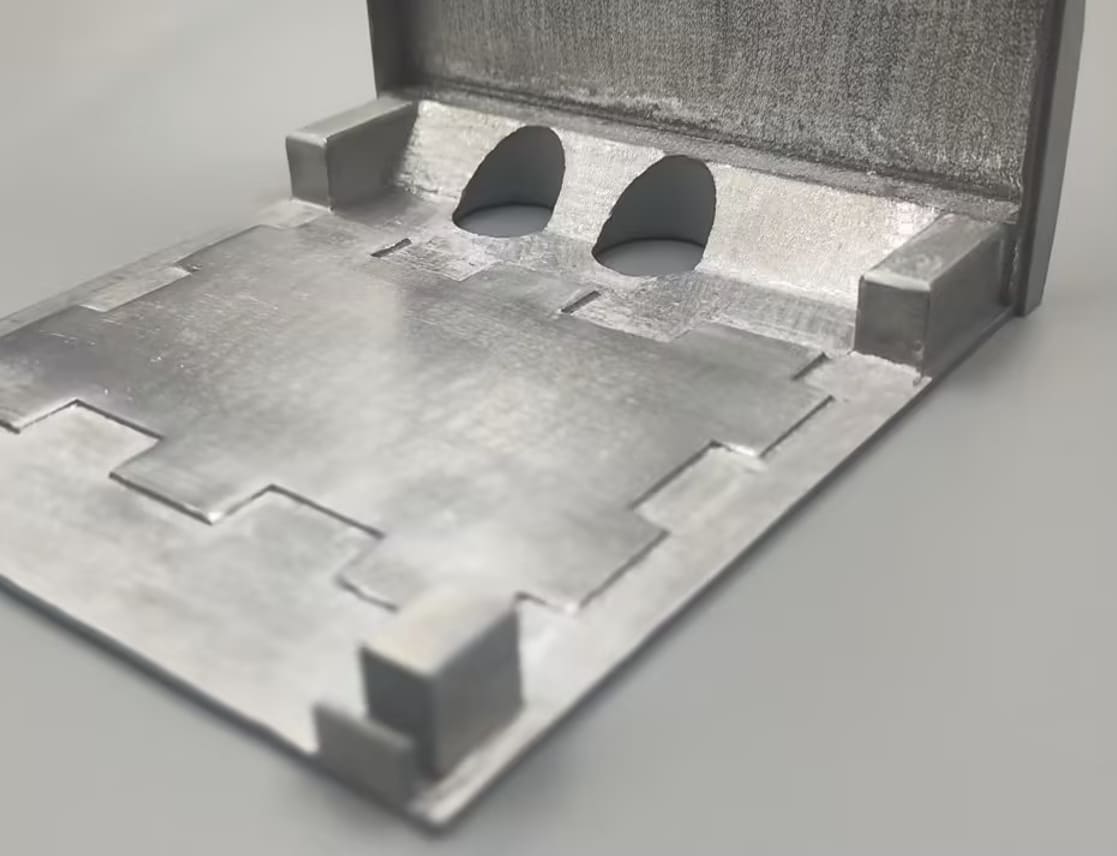

Metal Powder Bed Fusion

This category includes processes like Selective Laser Sintering (SLS), Selective Laser Melting (SLM), and Direct metal laser sintering (DMLS). These printers create parts by melting fine metal powder using a laser or electron beam. The process entails applying a fine layer of powder onto the build platform and then selectively fusing to create each layer of the object. The platform lowers, and the process repeats until the part is complete. Metal powder bed fusion is known for its fine details and is commonly used for complex, high-value parts.

SLM 3D Printed Manifolds at 3DSPRO

Directed Energy Deposition (DED)

DED employs a concentrated energy source, a laser or electron beam, to melt metal powder or wire as it's fed into the focus point of the beam, which is a versatile method. It's often used for repairing or adding material to existing components and building parts from scratch. DED can handle a wide range of materials and is particularly useful for large-scale parts, making it a method worth exploring for various applications.

Metal Filament Extrusion

This technique, similar to the Fused Filament Fabrication (FFF) method used in plastic 3D printing, offers adaptability. It utilizes a metal filament that undergoes heating and extrusion through a nozzle, incrementally constructing the part layer by layer. After printing, the part typically goes through a de-binding process to remove any binder used in the filament and then sintered to achieve full density. This method's versatility and adaptability make it a reliable choice for a variety of projects.

Material Jetting and Binder Jetting

These methods entail depositing a binding agent onto a bed of metal powder, layer by layer, to fabricate a part. Following printing, the part undergoes curing and subsequent sintering in a furnace. This process eliminates the binder and melds the metal particles together. This method is well-suited for producing parts with complex geometries and is also used for creating metal molds for casting.

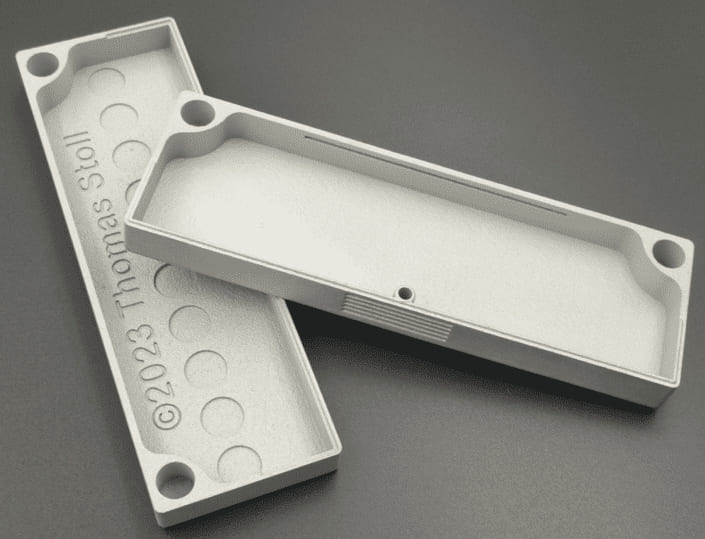

What is CNC machining?

CNC machining stands for Computer Numerical Control machining, a subtractive manufacturing process that employs computerized controls and machine tools to shape a workpiece into a desired final product. Unlike additive manufacturing methods like 3D printing, CNC machining removes material from a solid block—referred to as the workpiece or blank—using a variety of cutting tools to achieve the required geometry.

CNC machining consists of:

● CNC Milling: CNC milling involves using rotating cutting tools to remove material from the workpiece. CNC milling machines can move their tools and workpieces in multiple directions, allowing for the creation of complex shapes and features.

● CNC Turning: In this process, the workpiece rotates while a stationary cutting tool removes material, typically producing cylindrical parts.

CNC machining's precision and ability to produce parts with excellent mechanical properties make it a go-to choice for both prototyping and production. Its capacity to handle high-volume production runs, coupled with its efficiency in creating parts with tight tolerances and fine finishes, underscores its critical role in modern manufacturing.

Image Source: PROTOLABS NETWORK by Hubs

CNC Milling and CNC Turning

CNC milling and CNC turning are two fundamental processes in CNC machining, each with distinct methodologies and applications.

CNC Milling is characterized by its use of rotating cutting tools to remove material from a stationary workpiece. This versatile process can create a wide array of shapes, from simple flat surfaces to complex three-dimensional features. The milling machine’s cutting tools can move along multiple axes, allowing for operations such as drilling, boring, and slotting. CNC milling machines are classified based on their axis configuration, such as 3-axis, 4-axis, or 5-axis mills, each offering varying degrees of complexity and precision.

CNC Turning, on the other hand, involves securing the workpiece in a chuck and rotating it while a stationary cutting tool is fed into the material. This subtractive process excels at producing cylindrical parts with features like holes, grooves, and threads. The turning operation is typically performed on a CNC lathe or turning center, which can vary from simple 2-axis machines to more advanced multi-axis configurations.

Types of CNC Machines

CNC Lathe Machines

These machines are the modern-day equivalent of traditional lathes. They rotate the workpiece against a cutting tool to shape it into symmetrical objects, such as cones and cylinders. CNC lathe machines are prized for their precision and efficiency in producing parts like screws and automotive components.

CNC Milling Machines

CNC milling machines are renowned for their versatility, employing a rotating cutting tool to eliminate material from a fixed workpiece. They can move along multiple axes (3-axis, 4-axis, 5-axis, and even 6-axis) and produce diverse shapes, slots, holes, and intricate details. These machines are indispensable in creating complex parts with high precision.

CNC Drilling Machines

CNC drilling machines are designed to create cylindrical holes within a workpiece. They feature a rotating cutting tool, usually a drill bit, and can perform various drilling tasks, such as spot drilling, reaming, and tapping.

CNC Grinding Machines

The grinding machine uses a rotating abrasive wheel to achieve a fine finish or to make very precise cuts or holes. It is essential for finishing operations and is commonly used in the metalworking industry.

CNC Plasma Cutters

The Plasma cutter utilizes a plasma torch to cut through electrically conductive materials with high speed and precision. They are particularly useful for cutting metal sheets and are widely used in fabrication and automotive repair.

CNC Laser Cutters

With a high-powered laser, these machines can cut and engrave a variety of materials with extreme accuracy. CNC laser cutters are popular in industries that require intricate designs and detailing, such as electronics and textiles.

CNC Routers

Similar to milling machines but generally less robust, CNC routers are used to cut softer materials like wood, plastic, and foam. They are commonly found in woodworking shops for furniture design, sign-making, and more.

CNC Electrical Discharge Machines (EDM)

These machines use electrical sparks to mold materials into desired shapes. CNC EDM is particularly useful for hard metals and complex shapes that are difficult to machine with traditional methods.

Metal 3D Printing vs. CNC Machining: Mechanical Properties

Metal 3D printing and CNC machining have their unique strengths and limitations that can significantly impact the performance of the manufactured metal parts.

● Metal 3D Printing: Metal 3D printing is capable of making parts with complex geometries. Metal 3D printed parts can exhibit anisotropy—meaning their strength and mechanical properties may vary depending on the orientation in which the part was printed. This is due to the layer-by-layer construction method, which can create microstructures that differ from those found in bulk materials. Besides, metal 3D printed parts may require post-processing treatments like heat treatment or hot isostatic pressing (HIP) to enhance their mechanical properties and reduce anisotropy.

● CNC Machining: CNC machined parts, with their isotropic nature and uniform properties in all directions, are a testament to the precision and versatility of this method. They are carved from a solid block of material, ensuring that the microstructure remains consistent throughout the part. CNC machining can achieve greater dimensional accuracy and produce parts with better mechanical properties in all three dimensions compared to 3D printing.

Metal 3D Printing vs. CNC Machining: Materials

● Metal 3D Printing: Metal 3D printing primarily uses powdered metals, which are fused layer by layer to create the final part. Common materials include stainless steel, titanium, aluminum, and nickel-based alloys. These materials are chosen for their ability to be precisely controlled during the printing process. However, the range of materials available for metal 3D printing is limited compared to CNC machining, and the properties of printed parts can vary depending on the direction of the layers.

● CNC Machining: CNC machining uses a wide selection of metal materials, including all the metals available for 3D printing and additional options like brass, copper, and various grades of steel and aluminum. It can also handle harder materials like tool steel and certain superalloys that are challenging to print. The materials used in CNC machining maintain their bulk properties, providing consistent strength and durability across all dimensions of the part.

While metal 3D printing offers the advantage of creating lightweight, complex parts, CNC machining remains the preferred method for producing parts that require the full strength and properties of the chosen material without the need for additional processing. The decision between the two will depend on the specific requirements of the part, including material properties, part complexity, and the intended application.

Metal 3D Printing vs. CNC Machining: Advantages

Advantages of Metal 3D Printing:

● Design Freedom: Metal 3D printing excels in creating complex geometries, including internal channels and lattice structures, which are often impossible with CNC machining.

● Rapid Prototyping: It allows for quick iteration of designs, enabling faster development cycles and time-to-market.

● Material Efficiency: This process minimizes waste by using only the necessary material to build a part layer by layer.

● Customization: Each print can be easily modified to produce custom, one-off parts without the need for new tools or setups.

● Toolless Manufacturing: Unlike CNC machining, 3D printing does not require specialized tooling, which can reduce costs and lead times.

Advantages of CNC Machining:

● Precision and Accuracy: CNC machining is renowned for its high precision and ability to produce parts with tight tolerances.

● Material Selection: A wide variety of materials can be machined, including metals that are difficult to print.

● Surface Finish: Parts produced by CNC machining typically have a superior surface finish that may not require additional post-processing.

● Strength and Reliability: CNC machined parts are generally stronger and more reliable due to the consistent material properties throughout the part.

● Scalability: For large-scale production, CNC machining can be more cost-effective, especially as the volume of parts increases.

Metal 3D Printing vs. CNC Machining: Disadvantages

Disadvantages of Metal 3D Printing:

● Material Limitations: The range of materials suitable for metal 3D printing is narrower than that for CNC machining, and certain metals may not be available or may be cost-prohibitive.

● Mechanical Properties: Due to the layer-by-layer construction, parts produced by metal 3D printing can have variable mechanical properties, potentially leading to anisotropy.

● Surface Finish: The surface finish of 3D printed parts often requires post-processing to achieve the smoothness that CNC machining can provide directly from the machine.

● Speed and Productivity: While 3D printing is excellent for prototyping, it can be slower than CNC machining for mass production, especially for larger parts.

● Cost Efficiency: Metal 3D printing can be cost-effective for small production runs, but as the volume increases, CNC machining often becomes more economical.

Disadvantages of CNC Machining:

● Material Waste: CNC machining is a subtractive process, which means it can produce a significant amount of waste material, especially when creating complex geometries.

● Complexity Limitations: The parts that can be produced with CNC machining are limited geometrically, particularly internal features and undercuts.

● Setup Time: CNC machining requires setup for each new part, which can be time-consuming and costly, especially for custom one-off parts.

● Tooling Costs: The need for specialized tooling for different operations can add to the cost and lead times for CNC machined parts.

● Flexibility: While CNC machining is highly accurate, it lacks the design flexibility that metal 3D printing offers for complex and custom geometries.

Metal 3D Printing vs. CNC Machining: Manufacturing Speed

● Metal 3D Printing: Metal 3D printing is often celebrated for its rapid prototyping capabilities, allowing designers to iterate and refine designs quickly. The process can produce complex parts within hours or days, depending on the size and complexity of the part. However, for larger volumes or bigger parts, the production speed may not be as competitive. The layer-by-layer approach, while precise, is inherently slower than subtractive methods for mass production.

● CNC Machining: CNC machining is generally faster than 3D printing when it comes to producing parts, especially in larger volumes. The subtractive nature of CNC machining allows for the quick transformation of raw material into finished parts, often within hours. This makes CNC machining an excellent choice for high-volume production runs where speed is of the essence. Additionally, the absence of a need for post-processing, as is often required in metal 3D printing, contributes to a more streamlined and efficient production process.

Metal 3D Printing vs. CNC Machining: Cost

● Metal 3D Printing: Metal 3D printing is generally more cost-effective for small production batches, particularly when the parts have complex geometries that would be expensive to machine. The lack of a need for specialized tooling and the ability to print multiple parts simultaneously without intervention also contribute to cost savings. However, the initial investment in 3D printing technology can be significant, and the cost of metal powders can be higher than the bulk material used in CNC machining.

● CNC Machining: Due to economies of scale, CNC machining is typically more affordable for larger production volumes. The process can be faster and less labor-intensive per part, especially for simpler geometries. While the cost of tooling and setup can be high, especially for complex parts, the unit cost decreases significantly as the number of parts increases. Additionally, a variety of materials available for CNC machining allows for more cost-effective options.

Metal 3D Printing vs. CNC Machining: Volume

● Metal 3D Printing: Metal 3D printing maintains consistent material and operational costs per part, regardless of the production volume, due to the nature of the additive manufacturing process, where each part is built up layer by layer, and the machine setup remains relatively unchanged from one print to the next. While this means that 3D printing is less affected by the economies of scale that benefit CNC machining, it also provides a level of flexibility for producing small batches or custom parts without incurring additional setup costs.

● CNC Machining: CNC machining shines in scenarios where the production volume is high. The initial setup effort, which includes preparing the machines, designing the tools, and programming the operations, can be quite extensive. However, once the setup is complete, the cost can be spread across a large number of parts, making the per-unit cost significantly lower. This amortization of setup costs makes CNC machining an attractive option for large-scale production runs, where the efficiency gains contribute to a more cost-effective manufacturing process.

Metal 3D Printing vs. CNC Machining: Complexity

● Metal 3D Printing: Metal 3D printing thrives on complexity. The additive nature of the process allows for the creation of parts with intricate internal geometries, complex lattice structures, and detailed surface textures that would be challenging or impossible to achieve with CNC machining. This capability opens up new possibilities in design, such as topology optimization and lightweight, which can lead to performance improvements in various applications.

● CNC Machining: CNC machining, while precise and reliable, is constrained by the tool’s access to the material. Designs with deep cavities, undercuts, or internal features can be difficult or uneconomical to machine. The rotational nature of the cutting tools also means that sharp internal corners and certain types of fine detail may not be feasible. However, for external geometries and parts that require high precision and a smooth surface finish, CNC machining is often the preferred choice. The process is also well-suited for parts that need to withstand mechanical stress, as the material’s structural integrity is maintained throughout the machining process.

Metal 3D Printing vs. CNC Machining: Dimensional Accuracy

● Metal 3D Printing: Metal 3D printing can achieve good dimensional accuracy, suitable for a variety of applications. However, due to the nature of building parts layer by layer, slight variations can affect the final dimensions. Factors such as the printer's resolution, the material used, and the post-processing steps can influence the accuracy.

● CNC Machining: CNC machining is renowned for its exceptional dimensional accuracy and consistency. The subtractive process allows for tight tolerances and precise control over a part's final dimensions. The accuracy of CNC machining is less affected by material choice and does not typically require post-processing to meet dimensional specifications.

Metal 3D Printing Service at 3DSPRO

3DSPRO offers comprehensive metal 3D printing solutions and 3D Plus™ solutions that cater to the diverse needs of metal manufacturing. We provide SLM 3D printing service and various post-processing, such as annealing, spray painting, electrocoating, electroplating, tumbling, anodizing, polishing, etc.

We also offer a wide range of materials for metal 3D printing, such as aluminum, stainless steel, titanium, and more. By uploading your 3D models to our AI-powered quotation system, you can access the price and lead time of your part immediately.

At 3DSPRO, we ensure that innovators and manufacturers bring their visions to reality with unparalleled speed and quality.

COMMENTS

- Be the first to share your thoughts!