What is Laser Engraving

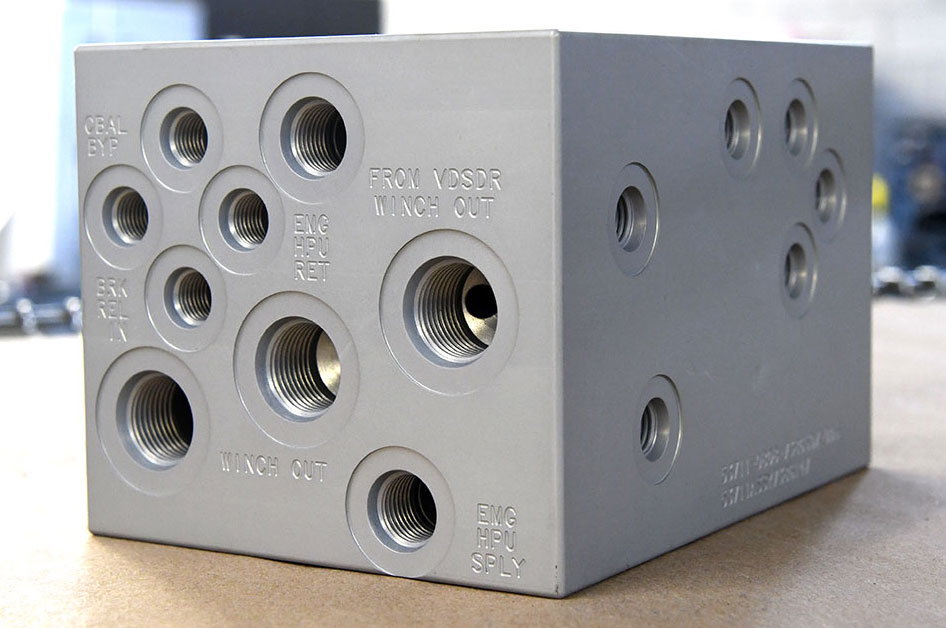

Laser engraving is a process that uses a highly focused beam of light to remove material from a surface, creating permanent marks, patterns, or designs. Unlike traditional engraving methods that rely on mechanical tools, laser engraving is non-contact, meaning the laser never physically touches the material. Instead, the beam vaporizes or burns away the surface layer with incredible accuracy.

Key Features of Laser Engraving:

• Precision: Lasers can engrave details as fine as a fraction of a millimeter.

• Durability: The marks are permanent and resistant to wear.

• Versatility: Works on a wide range of materials, from wood and leather to metals and plastics.

Laser engraving is often confused with laser cutting or laser etching. Cutting slices through materials entirely, while etching produces shallow marks. Engraving sits in between, deep enough to be permanent, but not cutting all the way through.

Image Source: JET HELSETH

Types of Laser Engraving Machines

CO₂ Laser Engraver

CO₂ laser engravers are the most common and versatile type, especially popular among hobbyists and small businesses. They use a gas mixture, primarily carbon dioxide, to generate infrared light, which is excellent for engraving organic materials like wood, leather, paper, and acrylic. If you’ve ever seen a beautifully engraved wooden sign or a personalized leather wallet, chances are it was done with a CO₂ laser. Affordable and widely available, these machines are a go-to choice for creative projects, though they struggle with bare metals unless special coatings are applied.

Fiber Laser Engraver

Fiber laser engravers are the powerhouse of the engraving world, designed for precision work on metals and certain plastics. Instead of gas, they rely on optical fibers to amplify light, producing a highly concentrated beam that can engrave stainless steel, aluminum, brass, and even industrial-grade plastics with incredible accuracy. Fiber lasers are the preferred option for industries that need permanent, high-contrast marks, think serial numbers on tools, barcodes on medical devices, or logos on jewelry. While they come with a higher upfront cost, their long lifespan and low maintenance make them a smart investment for professional use.

Diode Laser Engraver

Diode laser engravers are compact, budget-friendly machines that appeal to beginners and hobbyists. Built with semiconductor technology, they’re lightweight, portable, and easy to set up, making them perfect for small-scale projects like engraving soft woods, paper, or simple craft materials. While they don’t have the power to handle metals or large industrial jobs, diode lasers are an accessible entry point for anyone curious about laser engraving. They’re often used for DIY projects, personalized gifts, or creative experiments where affordability and convenience matter more than industrial strength.

Materials Suitable for Laser Engraving

Wood

• Engraves with warm, natural contrast and visible grain patterns.

• Best for signage, furniture, crafts, and personalized décor.

• Hardwoods (oak, maple) produce sharp detail; softwoods give lighter tones.

Plastics

• Acrylic, ABS, and polycarbonate engrave cleanly with sharp edges.

• Popular for labels, prototypes, and signage.

• Settings must be adjusted to avoid melting or toxic fumes.

Metals

• Stainless steel, aluminum, and brass are common choices.

• Ideal for jewelry, industrial parts, and branding.

• Fiber lasers deliver crisp, permanent marks resistant to wear and corrosion.

Glass & Ceramics

• Produce frosted, elegant designs with a matte finish.

• Perfect for awards, drinkware, and decorative items.

• Requires careful handling to prevent cracking or shattering.

Leather & Textiles

• Used in fashion, accessories, and personalized gifts.

• Creates stylish engravings on wallets, belts, and fabric patches.

• Works best with natural leather; synthetics may burn unevenly.

The Process of Laser Engraving

Laser engraving may sound complex, but the workflow is straightforward once you understand the steps:

1. Design Creation: Artwork is prepared using software like CorelDRAW, AutoCAD, or LightBurn.

2. Machine Setup: Adjust laser settings, power, speed, and focus, based on the material.

3. Material Preparation: Secure the material on the engraving bed.

4. Engraving: The laser beam follows the design, removing material layer by layer.

5. Post-Processing: Clean the engraved surface, sometimes polish or add finishes.

Applications

Industrial Manufacturing

• Used for serial numbers, barcodes, and compliance markings on tools, machinery, and automotive parts.

• Ensures traceability and durability in harsh environments.

Jewelry & Fashion Accessories

• Engraves intricate designs, initials, or logos on rings, watches, and pendants.

• Adds value through personalization and craftsmanship.

Gifts & Crafts

• Popular for customized photo frames, ornaments, and keepsakes.

• Perfect for weddings, anniversaries, and holidays where personalization makes items memorable.

Signage & Branding

• Creates professional logos, plaques, and promotional items.

• Offers sharp detail for both indoor and outdoor signage.

Electronics & Medical Devices

• Mark circuit boards, connectors, and surgical instruments with permanent IDs.

• Critical for safety, compliance, and quality assurance.

Home & Lifestyle Products

• Engraves décor items, kitchenware, and even phone cases.

• Adds a unique, customized touch to everyday objects.

Pros and Cons

|

Pros |

Cons |

|

High precision and detail, capable of engraving fine lines and complex patterns |

High initial machine cost, especially for fiber lasers |

|

Works on a wide range of materials including wood, metal, plastic, glass, and leather |

Requires training to master software and machine settings |

|

Permanent, durable marks resistant to wear, fading, or corrosion |

Safety concerns such as fumes and eye protection requirements |

|

Fast and efficient for both one-off projects and mass production |

Not all materials are suitable (e.g., PVC releases harmful gases) |

|

Non-contact process reduces wear and tear on tools and materials |

Maintenance and ventilation systems add to operating costs |

Laser Engraving vs Laser Etching

These two terms are often used interchangeably, but they’re different:

• Laser Engraving: Removes material to create deep, permanent marks. Best for durability and readability.

• Laser Etching: Alters the surface by melting or discoloring it, creating shallow marks. Faster but less durable.

|

Feature |

Laser Engraving |

Laser Etching |

|

Depth |

Deep, permanent |

Shallow |

|

Durability |

High |

Moderate |

|

Speed |

Slower |

Faster |

|

Best For |

Industrial marking, jewelry, signage |

Decorative items, quick personalization |

Think of engraving as carving into the material, while etching is more like surface decoration.

3DSPRO Opens Manual Quotation for Laser Engraving

We open manual quotation services for laser engraving so that customers can now request tailored quotes for their projects, ensuring transparency and flexibility. Contact SUCCESS@3DSPRO.COM for manual quotation services.

Customers Can Enjoy

• Personalized pricing that reflects the unique scope and complexity of each project.

• Simplified budgeting for both individuals and businesses, with clear cost breakdowns.

• Freedom to experiment with custom designs without worrying about hidden costs.

Customers Can Expect

• Direct communication with the 3DSPRO team for guidance and support.

• Flexible options across different materials and machine types to suit diverse needs.

• Scalable solutions for everything from one-off creative pieces to large industrial orders.

Whether you’re ordering a single custom 3D printed gift or planning a large production run, manual quotations help bridge the gap between creativity and affordability.

COMMENTS

- Be the first to share your thoughts!