For electronic enclosures, transportation interiors, consumer products, and many industrial parts, controlling how a polymer behaves in a fire is a function of both safety and regulatory compliance. Traditional plastics can ignite, drip flaming droplets, produce dense smoke, or generate toxic gases. Flame-retardant materials, either inherently flame-resistant polymers or formulations that include FR additives, reduce ignition likelihood, slow flame spread, promote charring, or limit flaming drips. Selecting the right FR material and validating it with the correct tests keeps products safe and helps meet code and customer requirements.

What Flame-Retardant Means?

Flame-retardant describes a material behavior, not a single chemistry.

A few practical distinctions:

• Self-extinguishing vs. non-flammable: Self-extinguishing materials will stop burning after an ignition source is removed; “non-flammable” is rarely absolute for polymers.

• Mechanisms of action: Common mechanisms include (a) endothermic decomposition that absorbs heat and releases water (common in mineral hydrates), (b) char formation that creates a protective barrier, (c) gas-phase radical trapping (halogenated or phosphorus chemistries) that interrupts combustion chemistry, and (d) dilution of combustible volatiles.

Understanding the mechanism helps predict side effects like smoke, corrosive gases, or loss of mechanical properties.

Two widely used test concepts that help quantify “flame-retardant” are the UL 94 flammability classifications for plastics (vertical and horizontal burn tests, dripping behavior and afterglow) and the Limiting Oxygen Index (LOI), which measures the minimum oxygen concentration that will sustain burning. UL 94 classifies materials into ratings such as V-0, V-1, and V-2 based on burning time and flaming drips; LOI values higher than atmospheric (≈21%) indicate reduced flammability.

Common Flame-Retardant 3D Printing Materials

3D printing uses a variety of chemistries and FR approaches. Below are the most common families you’ll see in filament and resin form:

Inherently Flame-Resistant Engineering Thermoplastics (e.g., PEI / ULTEM)

Some high-performance polymers are naturally resistant to flame and smoke without heavy additive loadings. ULTEM® (polyetherimide, PEI) is known for high glass transition temperature, excellent thermal stability, and grades with UL-ratings, making it a frequent choice for demanding applications in aerospace and electronics where both heat resistance and flame performance matter.

Flame-Retardant Modified Thermoplastics (FR-ABS, PC-ABS, FR-PLA)

Manufacturers produce ABS and PC blends and specially compounded FR grades that achieve UL94 V-0 at specific thicknesses. These are popular for FDM/FFF printing because they balance printability with improved flame performance. Many filament vendors sell UL-tested FR-ABS and PC-ABS grades suitable for enclosure parts.

Mineral-Filled Composites (ATH, Magnesium Hydroxide)

Non-halogenated mineral fillers like aluminum trihydrate (ATH) and magnesium hydroxide are common FR fillers. They decompose endothermically at elevated temperatures and release water, cooling the polymer and diluting flammable gases; they also increase char or ceramic residue. These fillers are effective and relatively inexpensive but require high loading levels that can reduce toughness and make filaments more abrasive to nozzles.

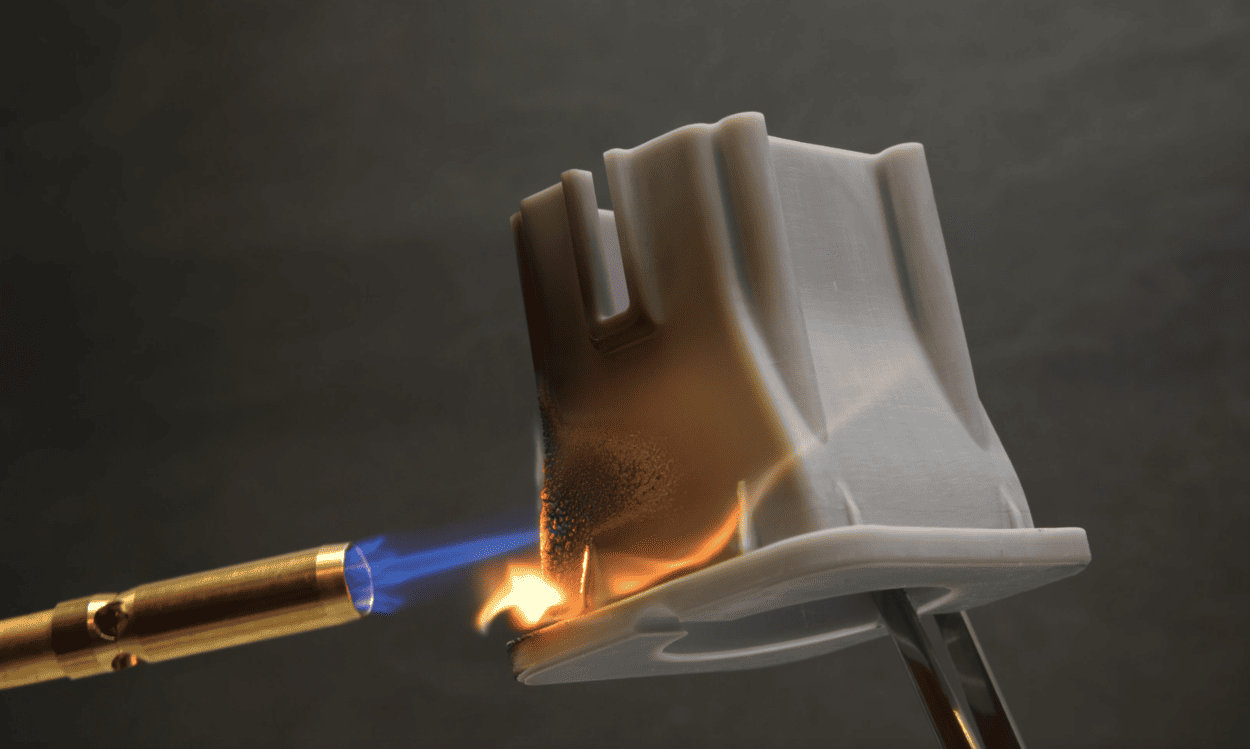

Flame-Retardant Photopolymer Resins (SLA/DLP)

For resin printing, manufacturers produce FR-resins with phosphorus or halogen-free chemistries that are formulated to meet specific flammability ratings while retaining cure behavior. Because post-cure and resin chemistry strongly affect properties, careful process control is important.

Image Source: Formlabs

Performance and Mechanical Considerations

Mechanical Trade-offs

High filler loadings (ATH, metal oxides) reduce polymer ductility and impact strength; lower-loading phosphorus systems may preserve toughness better but can be costlier. Inherently FR polymers like PEI maintain much of their mechanical performance but usually require higher processing temperatures and sometimes specialized printers.

Printability

Abrasive fillers accelerate nozzle wear; blends may need different extrusion temperatures and slower print speeds. FR chemistries can change melt viscosity and interlayer adhesion, so calibration and design compensation (higher shell counts, thicker layers, or adjusted infill) are common.

Thermal Aging & UV Exposure

Some FR additives change behavior over time; for long-lived parts, consider aging tests. Smoke and toxicity profiles of combustion products also vary: halogenated systems can produce corrosive or toxic gases, which is why many industries prefer halogen-free alternatives where possible.

Mitigation Strategies

Use hardened nozzles (steel, ruby), tune extrusion and cooling settings, consider post-processing (annealing to improve interlayer strength), and choose FR systems that match the mechanical and environmental needs of the part.

Testing Standard

UL 94 (Vertical/Horizontal Tests)

Measures burning time, afterglow, and whether flaming drips ignite cotton placed beneath the sample. Ratings such as V-0 indicate rapid self-extinguishing without flaming drips, a common requirement for electronic housings.

LOI (ASTM D2863 / ISO 4589)

Gives a quantitative oxygen concentration necessary to sustain combustion; higher LOI = better resistance. Materials with LOI above 21% are less likely to burn in normal air.

ASTM E84 / NFPA 255 (Surface Burning Characteristics)

Relevant when surface flame spread and smoke generation are important (e.g., interior panels, building materials). The tunnel test reports the flame spread index and the smoke developed index.

Sample Preparation Matters

A UL-rated base resin does not automatically guarantee that a printed part will meet the same rating, print thickness, part geometry, porosity, and post-processing change performance. Always test printed coupons made with the intended process and post-treatments.

Applications

Flame-retardant 3D printed parts appear in many markets:

• Electronics & housings: Consumer and industrial electronic enclosures often require UL ratings to reduce the risk of ignition and flaming drips. FR-ABS, PC-ABS blends, or PEI are common choices.

• Transportation interiors: Automotive and aerospace components need low smoke and flame performance; inherently FR polymers (PEI/ULTEM) or intumescent systems are common in these regulated environments.

• Industrial equipment: Guards, brackets, and housings near heat sources benefit from FR materials and good thermal design.

• Public & architectural elements: When printed decorative or functional parts are in occupied spaces, surface burning tests like ASTM E84 may be required.

In all cases, designers must weigh material cost, print complexity, mechanical needs, and regulatory limits. For small-scale production or custom parts, it’s frequently faster and less expensive to select an FR material and test printed prototypes than to redesign an enclosure for distance or shielding alone.

Get Instant Quotes and Order 3D Printed FR Resin Parts at 3DSPRO

COMMENTS

- Be the first to share your thoughts!