What is PolyJet 3D printing?

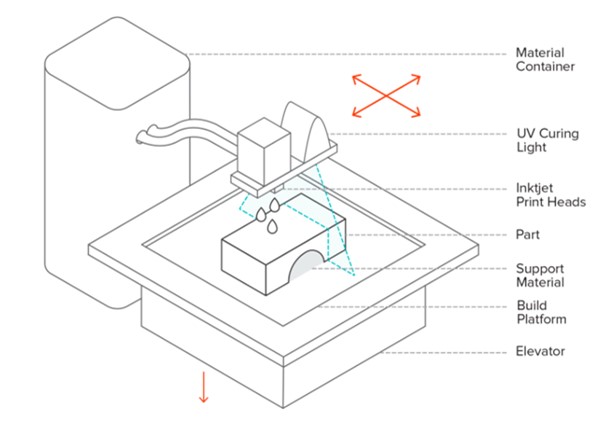

PolyJet 3D printing works by spraying a layer of curable liquid photopolymer onto a build platform.

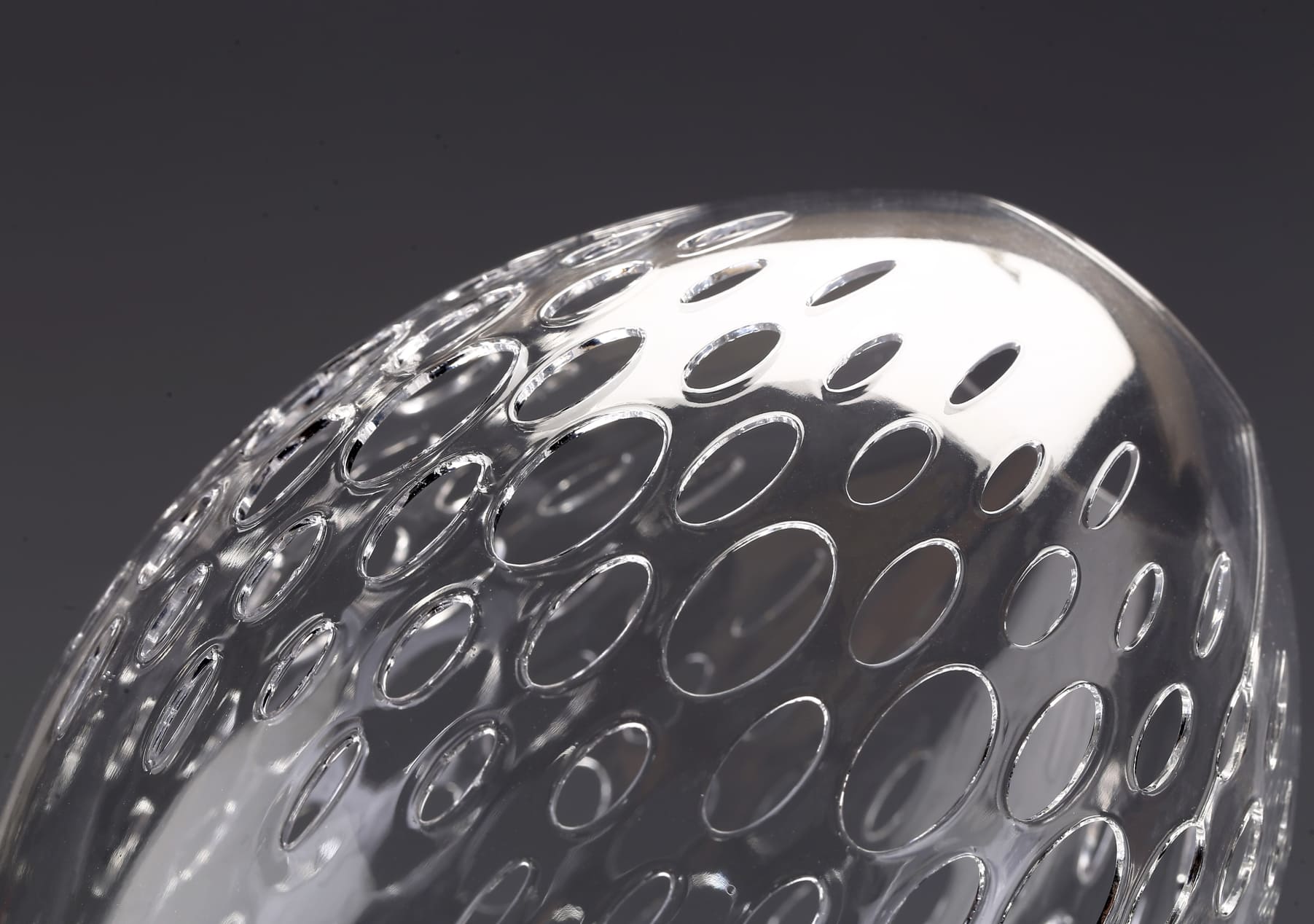

PolyJet utilizes inkjet-like print heads that spray tiny droplets of the photopolymer material, which are immediately cured by ultraviolet (UV) light. It can create parts with smooth surfaces and a high level of detail that rivals injection-molded parts.

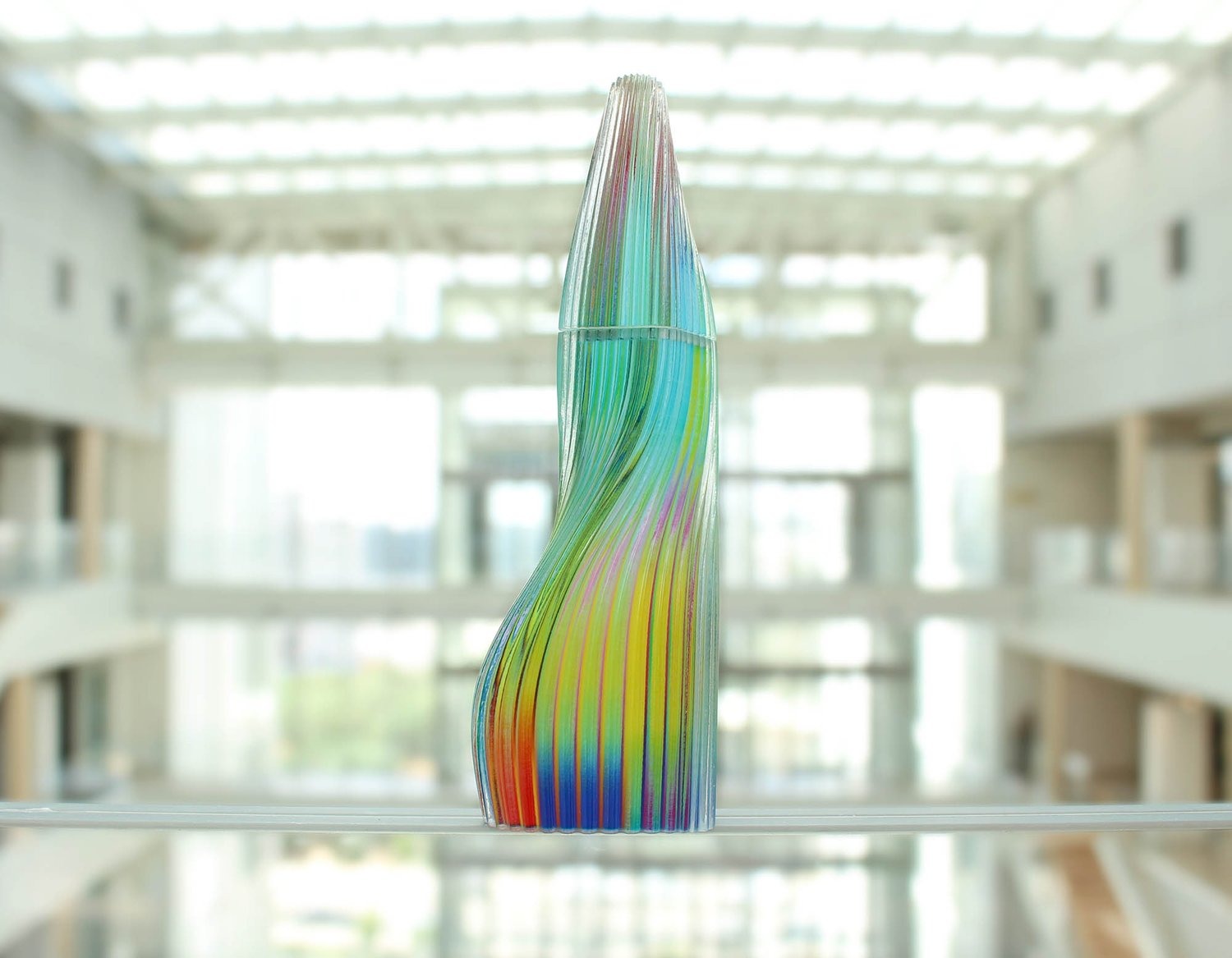

One of PolyJet's most remarkable features is its multi-material capabilities. It can print with several different materials in a single print job, including materials with varying colors and mechanical properties. Therefore, PolyJet is capable of creating prototypes that closely resemble the final product not only in form but also in function and aesthetics.

PolyJet provides unmatched precision, material flexibility, and rapid production capabilities, making it an exceptional option for rapid prototyping. Designers and engineers can rapidly iterate designs, transitioning from concept to tangible object in significantly less time compared to conventional manufacturing techniques.

Image Source: Stratasys

PolyJet 3D Printing Process

Here is the step-by-step overview of the PolyJet 3D printing process:

1. Preparation

It begins with a meticulously crafted 3D model in a computer-aided design (CAD) program. The 3D model is then converted into a format suitable for 3D printing, typically STL, STP, or OBJ.

2. Printing

The PolyJet printer prepares for action, warming up its print heads. These heads are akin to those found in inkjet printers but are engineered to jet out photopolymer rather than ink. The printer jets thousands of tiny droplets of photopolymer onto a build tray, layer by delicate layer.

3. Curing

As each layer is deposited, it’s instantly cured and solidified by ultraviolet (UV) light, ensuring that the details are crisp and the surfaces are smooth.

4. Supports

For overhangs and some complex geometries, the printer simultaneously jets a removable support material. The support material props up the design as it takes shape, ensuring every nuance is captured.

5. Layering

The process repeats, with each layer bonding to the last, gradually building up the object in all its intricate glory.

6. Post-Processing

Once the printing is complete, the object is removed from the build tray. The support material is then washed away or manually removed to reveal the final product.

7. Finishing Touches

The PolyJet-printed object may undergo additional post-processing or finishing to achieve the desired aesthetic quality, such as water jetting, sanding, or painting.

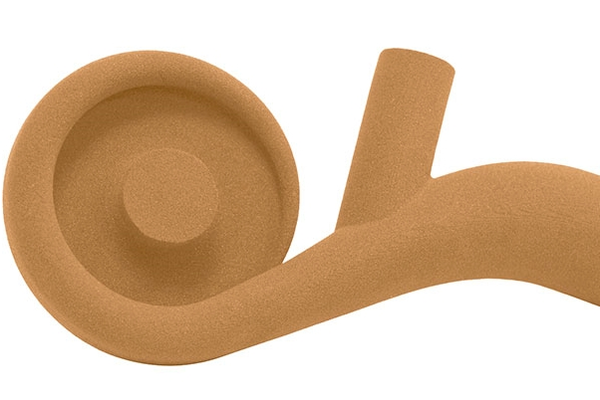

Image Source: Mizar Additive Manufacturing

What type of 3D printer is PolyJet?

PolyJet is a type of 3D printer that falls under the category of material jetting. It is known for its ability to print multiple materials and colors in a single build process, which sets it apart from other 3D printing technologies.

The PolyJet printer operates similarly to an inkjet printer but with a significant twist. Instead of ink, it jets a photopolymer material that is immediately cured by ultraviolet (UV) light. PolyJet printers are particularly adept at creating prototypes that require fine detail and a smooth surface finish. They can produce parts with varying textures, colors, and material properties, all within the same print job. The technology is also capable of printing in high resolution.

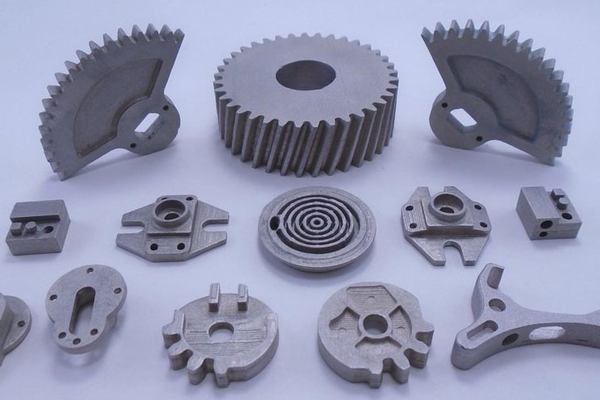

In terms of applications, PolyJet printers are versatile and can be used across various industries, from medical and dental to consumer products and electronics. They are ideal for producing realistic prototypes, models, and even end-use parts that require a high level of detail and precision.

Image Source: Stratasys J5 DentaJet

PolyJet Materials

PolyJet 3D printing technology is known for its wide range of material options to meet a variety of applications and design requirements.

● Digital Materials: These are unique to PolyJet printing. They are created by blending up to seven different photopolymer resins in specific concentrations and structures to achieve desired mechanical properties and textures.

● Digital ABS Plastic: Designed to mimic the durability and heat resistance of Acrylonitrile Butadiene Styrene (ABS) thermoplastic, Digital ABS is ideal for functional prototypes that require toughness and thermal stability.

● Transparent Materials: PolyJet offers materials that can simulate glass or transparent plastic, allowing for the creation of clear components or prototypes with see-through elements.

● Rubber-like Materials: With varying degrees of flexibility and color options, these materials can simulate rubber, providing the necessary elasticity for parts like gaskets, hoses, and seals.

● Biocompatible Materials: These are specially formulated for medical and dental applications and meet the necessary safety standards for bodily contact.

● High-Temperature Materials: PolyJet provides materials that can withstand elevated temperatures without deforming for applications that demand stability under high thermal conditions.

● Simulated Polypropylene: Offering the resilience and durability of polypropylene, these materials are suitable for prototypes that need to replicate the characteristics of this common plastic.

● Full-Color Materials: PolyJet’s ability to print in full color enables the production of models that feature intricate color patterns and gradients, enhancing the visual appeal and realism of prototypes.

Image Source: Stratasys VeroVivid Color Family

PolyJet Pros and Cons

Pros

● Multi-Material Capability: PolyJet can print with multiple materials in one go, including transparent and rubber-like properties, simulating common thermoplastics like ABS.

● Full-Color Printing: It is one of the few technologies that allow for full-color 3D printing, making prototypes visually realistic.

● High Precision: PolyJet is known for its high accuracy, capable of up to 16 microns, and the ability to create extremely smooth finishes.

● Speed: It can create multicolor parts much faster than most other 3D printing technologies.

● Ease of Post-Processing: The support material is easily removable by hand, which is less labor-intensive than other methods like SLA.

Cons

● Support Material: Areas where support material is used, may have reduced surface quality, and removal of supports might affect the final part’s precision.

● Rounded Edges: Sharp edges can become rounded due to the nature of the printing process, leading to a loss of detail in certain areas.

● Cost: The materials and machinery used in PolyJet printing can be more expensive compared to other 3D printing technologies.

● Material Limitations: While it offers a variety of materials, they are all photopolymers, which may not meet the performance standards of all engineering plastics.

Is PolyJet better than SLA?

Both are advanced resin-based 3D printing technologies that use UV light to cure liquid resin, but they have distinct differences that make them suitable for different scenarios.

Take A Look at SLA Advantages:

● Large Format Parts: SLA is more suitable for producing large-format parts.

● Consistent Speed: SLA printing maintains a consistent speed regardless of the model's size.

● Cost-Effectiveness: SLA can be more cost-effective, especially for single-material prints.

Considerations

● Application: PolyJet's quick material change capability makes it ideal for prototypes and low-volume production, while SLA is more suited for larger, single-material parts.

● Detail and Precision: If high detail and precision are required, PolyJet may be preferable.

● Budget: SLA might be a better option for those working with a limited budget or needing to produce larger objects.

In conclusion, PolyJet offers a high degree of flexibility and precision, making it excellent for complex prototypes and multi-material parts. SLA, on the other hand, is a reliable choice for larger parts and can be more cost-effective for certain applications. The decision between PolyJet and SLA ultimately depends on the specific requirements of the project.

PolyJet Applications

PolyJet is applied in various fields:

Medical and Dental

In the medical industry, PolyJet is used for creating detailed anatomical models for surgical planning and educational purposes. The dental sector utilizes it for accurate dental molds and orthodontic appliances.

Prototyping

Designers leverage PolyJet for form, fit, and function testing. It’s ideal for prototyping complex parts, especially when multiple material properties or colors are needed to simulate the final product.

Consumer Goods

For consumer products, PolyJet is perfect for creating realistic prototypes with the exact color and feel of the intended final item, such as a hand drill with a soft grip handle.

Education

Educational aids and toys benefit from PolyJet’s ability to produce colorful and detailed items that can withstand handling by students and children.

Overmolding

PolyJet can simulate manufacturing processes like overmolding, allowing for the creation of flexible, rubber-like models with ‘zero slip’ or soft surfaces.

Jewelry Design

The high resolution of PolyJet printing makes it suitable for jewelry design, where precision and detail are paramount.

Microelectronics

Microelectronics prototyping is another area where PolyJet excels, thanks to its ability to reproduce extremely fine details and complex geometries.

Image Source: Stratasys

COMMENTS

- Be the first to share your thoughts!