What is Binder Jetting in 3D printing?

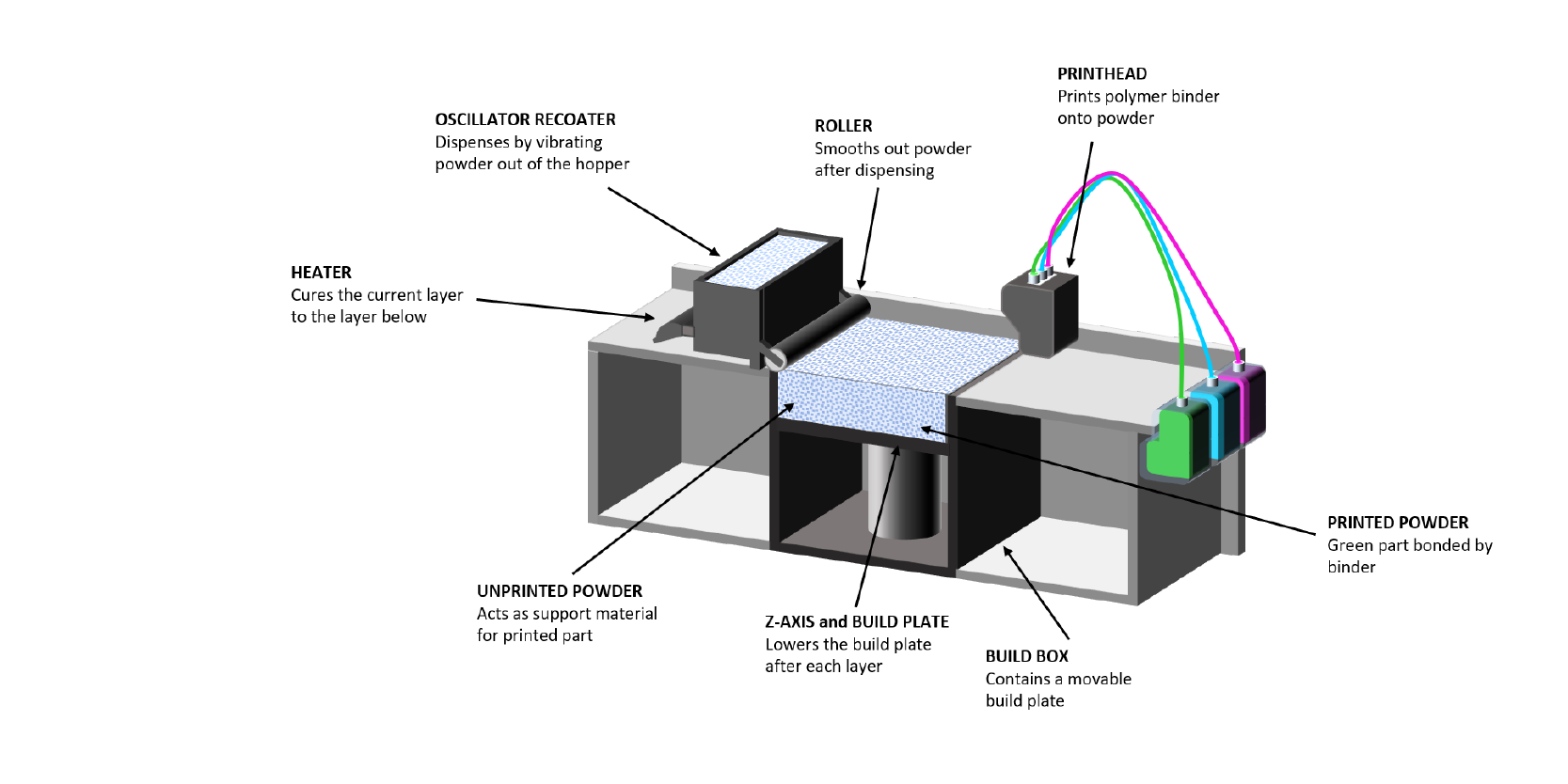

Binder Jetting is utilized across diverse industries for various applications. In this process, a powdered material (such as metals, ceramics, or sand) serves as the base. Layer by layer, a liquid binding agent is selectively deposited onto the powder bed to create the desired part. Each layer is built sequentially until the complete 3D model is created.

Binder Jetting combines elements of Selective Laser Sintering (SLS) and Material Jetting. Notably, it offers versatility, high printing speeds, and doesn’t require support. Once printed, the part cures and gains strength. The unbound powder is removed, resulting in accurate and complex parts. Binder Jetting is opening up possibilities.

Image Source: ExOne

Binder Jetting 3D Printing Process

Binder Jetting is a lesser-known but powerful 3D printing technique. It finds applications primarily in two areas:

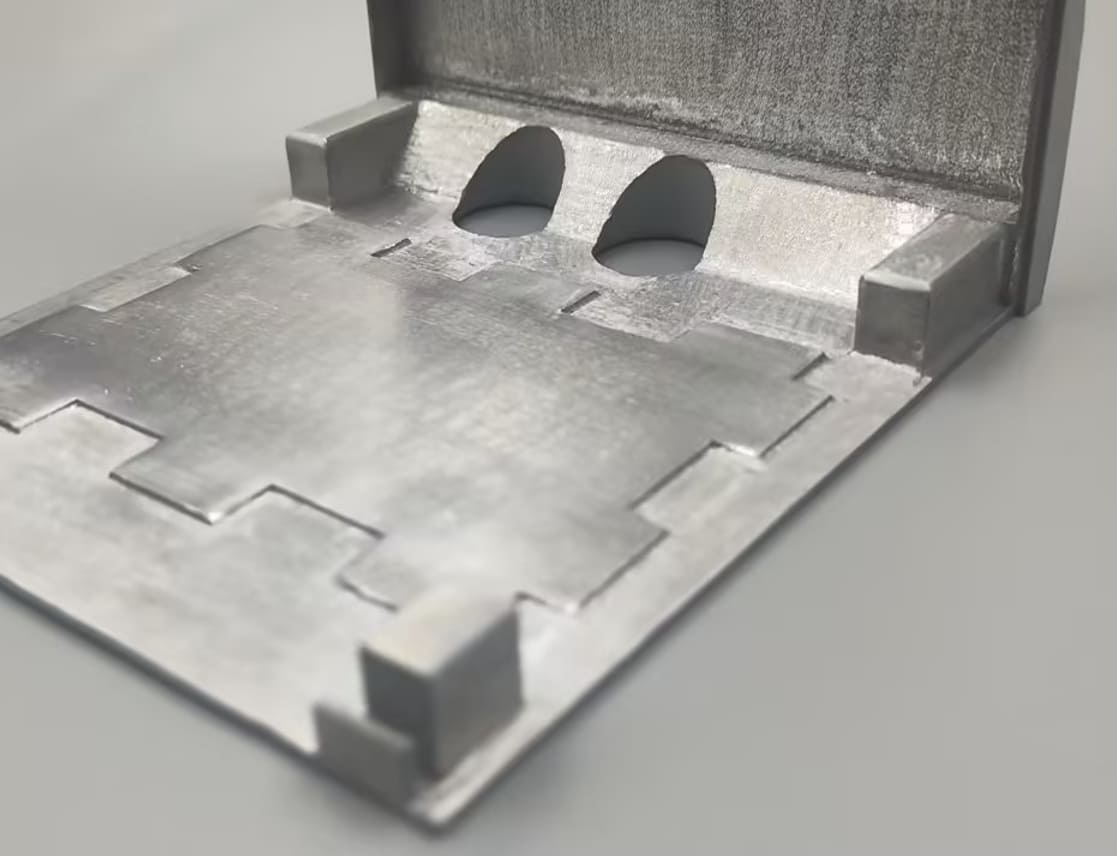

1. Metal 3D Printing

In metal 3D printing, Binder Jetting creates intricate metal parts.

Here’s how the process works:

1. Powder Material: Begin with a powder material (such as metal powder).

2. Binding Agent Deposition: A printhead selectively deposits a binding agent onto the powder bed, layer by layer.

3. Layer-by-Layer Formation: Each layer is built sequentially until the complete part is formed.

4. Hybrid Approach: Binder Jetting combines elements of Selective Laser Sintering (SLS) and Material Jetting. It uses powdered material (similar to SLS) and a binding agent (similar to Material Jetting) to create the 3D model.

5. Accuracy and Finish: The quality of the binder-jetted object depends on factors like layer height, droplet size, and powder size.

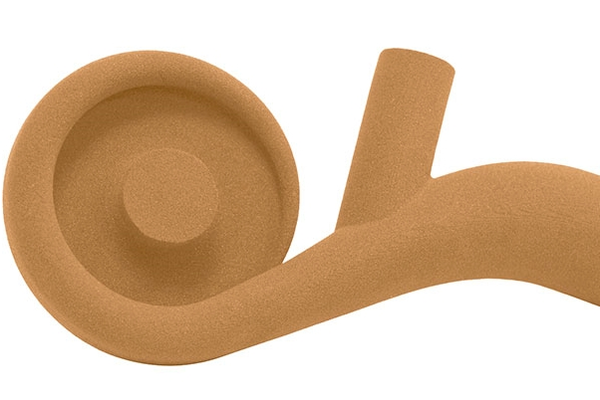

2. Sand Models and Casts

Binder Jetting is also employed in creating sand models and casts.

The process:

1. Use a powder material (such as sand).

2. Apply a liquid binding agent layer by layer.

3. Build up the layers to form the desired shape.

How It Works

1. A printhead moves over the powder surface, depositing tiny binder droplets (approximately 50 microns in diameter).

2. These binder droplets bind the powder particles together, forming each layer of the final 3D model.

3. Once each layer is finished, the powder bed descends, and a fresh layer of powder is uniformly spread over the previously printed one.

4. The accuracy and finish of the binder-jetted object depend on factors like layer height, droplet size, and powder size.

Post-Printing

1. After printing, the parts need to cure and gain strength.

2. The unbound powder is removed using compressed air.

3. Unlike some other 3D printing methods, supports are not required because parts are surrounded by powder, which reduces post-processing time and material consumption.

Image Source: Freeman Technology

Binder Jetting Pros and Cons

Pros

1. Room Temperature Process

● The primary advantage of Binder Jetting is that the process occurs at room temperature.

● Unlike some other 3D printing methods, there are no thermal effects causing part distortion.

● Binder Jetting allows for larger build volumes, making Binder Jetting machines suitable for mass production.

2. Cost-Effective and Energy-Efficient

● Binder Jetting uses a liquid binding agent instead of a laser, which makes it more energy-efficient.

● The process also utilizes affordable materials, resulting in low operating costs per part produced.

● It’s an ideal choice for precise and scalable mass production of small yet accurate objects.

3. No Supports Required

● Unlike Fused Deposition Modeling (FDM) or Stereolithography (SLA), Binder Jetting doesn’t require support.

● Parts are surrounded by powder, reducing post-processing time and material consumption.

Cons

1. Limited Material Options

● Binder Jetting offers a narrow range of materials, restricting its use in diverse applications.

● While it works well for metals, ceramics, and sand, it may be suitable for something other than specialized materials.

2. High Post-Processing Time

● After printing, Binder Jetted parts need curing and strengthening.

● This additional step can result in longer lead times compared to some other 3D printing methods.

Binder Jetting Materials

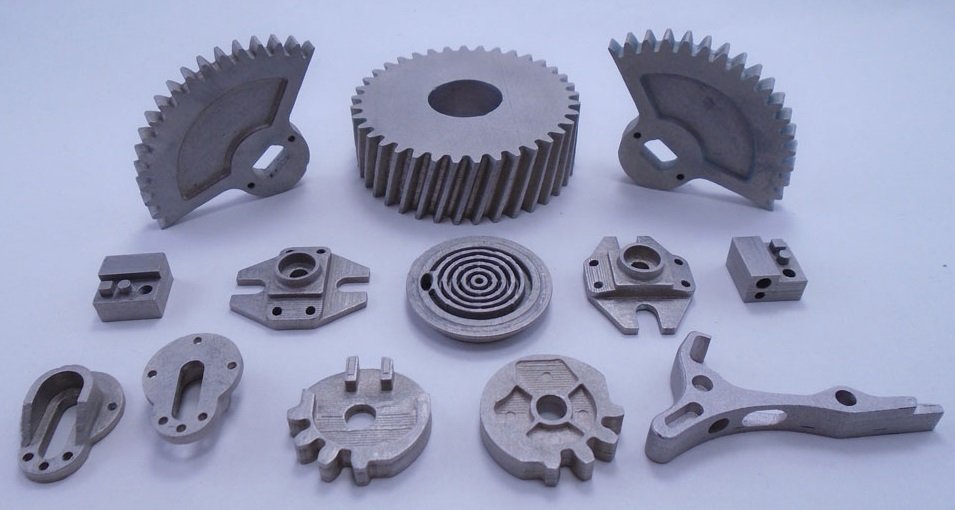

1. Metals

Metal binder jetting can process a variety of metal powders, including:

● Stainless steel

● Inconel

● Copper

● Titanium

● Tungsten carbide

2. Ceramics

Ceramic materials are also compatible with binder jetting. Examples include:

● Alumina

● Zirconia

● Silicon carbide

3. Sand

Sand binder jetting is particularly useful in the foundry industry. It allows for the creation of sand molds and cores for casting processes.

4. Other Materials

Beyond metals and ceramics, binder jetting can also work with other materials like polymers.

Image Source: 3DEO

Binder Jetting vs. Material Jetting

Binder Jetting (BJ)

Process

In binder jetting, powdered materials (such as metal, sand, plaster, or ceramics) are deposited layer by layer.

Printing Mechanism

A liquid binder (usually a polymer binding agent) is selectively printed onto the powder bed. The binder solidifies on contact to bond the powder particles together within a model slice.

Advantages

1. Faster than many other 3D printing methods.

2. Cost-effective for bulk production due to low material costs.

3. No need for extensive support structures.

4. Capable of printing metal parts directly.

Disadvantages

1. Lower resolution compared to some other techniques.

2. Resolution issues due to capillary action bleeding the binder into the surrounding powder.

3. Limited color options.

Applications

Suitable for low-resolution parts across a wide range of materials.

Material Jetting (MJ)

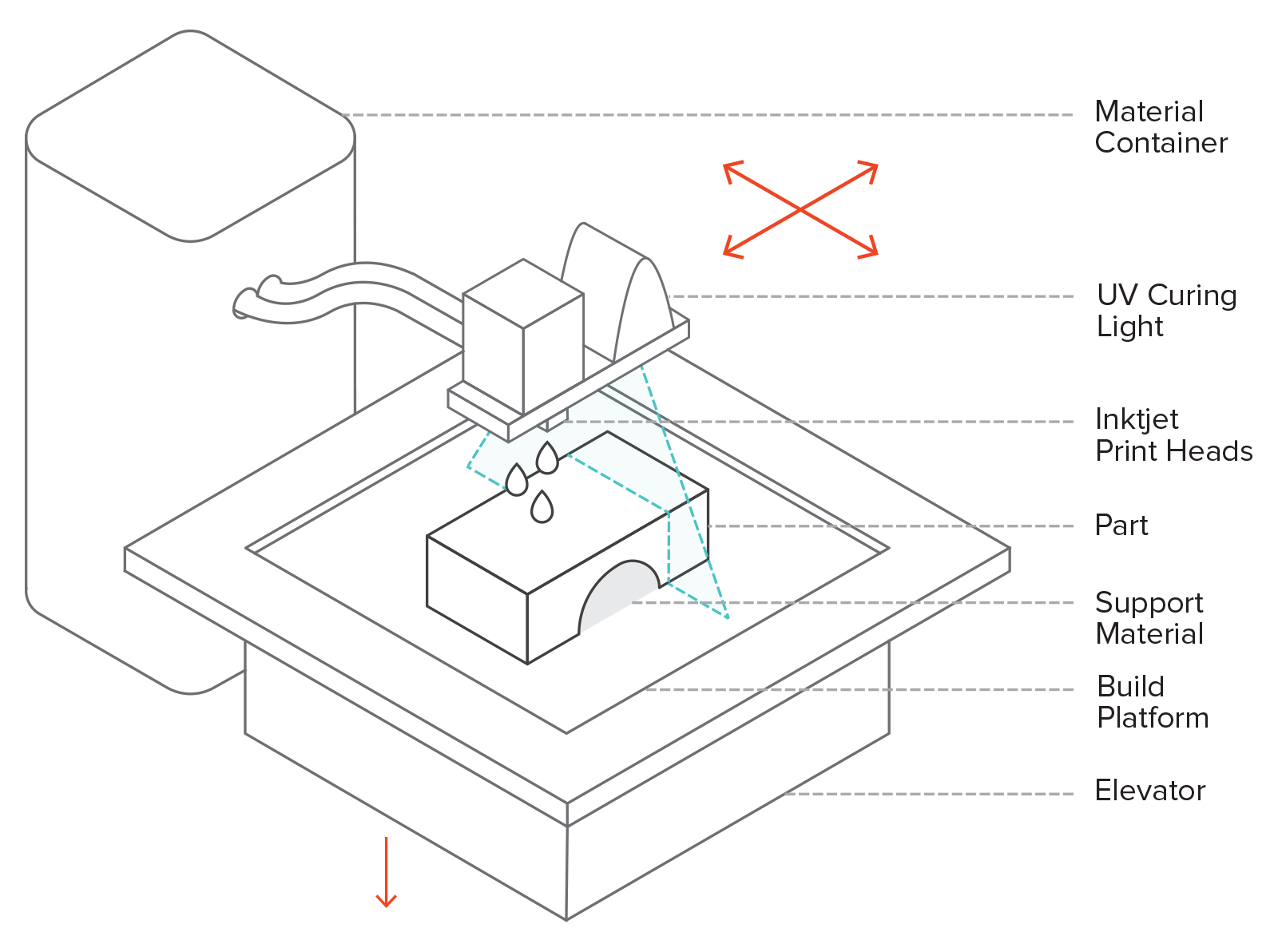

Process

Material jetting is based on the same principle as 2D printing. Multiple printheads deposit droplets of material (usually photosensitive resin or photopolymer) onto a build table. UV light hardens the material.

Printing Mechanism

Material jetting directly prints model slices onto the build table.

Advantages

1. High resolution, suitable for detailed plastic prototypes and models.

2. Can combine multiple photopolymers and colors.

3. Fast printing speed.

Disadvantages

1. It may be costlier due to material properties.

2. Requires support structures (removed after printing).

Applications

Ideal for detailed prototypes, models, and parts requiring high resolution.

In summary, Binder Jetting is cost-effective for bulk production but has lower resolution, while Material Jetting offers higher resolution but may be more expensive. The choice depends on specific project requirements like resolution, materials, and production volume.

Image Source: Protolabs Network by Hubs

Binder Jetting Applications

Binder Jetting offers a wide range of applications, from aerospace to healthcare and from art to construction.

1. Automotive Industry

● Prototypes: Binder Jetting is used to create functional prototypes for testing and validation.

● Tooling Components: It produces tooling components like jigs, fixtures, and molds.

2. Aerospace Sector

● Lightweight Parts: Binder Jetting allows for the manufacturing of lightweight yet durable components for use in aircraft and spacecraft.

● Complex Geometries: It’s ideal for creating intricate components with complex geometries.

3. Healthcare and Medical Devices

● Anatomical Models: Binder Jetting helps create accurate anatomical models for surgical planning and education.

● Dental Restorations: It’s used in dental labs for crowns, bridges, and dentures.

4. Foundry Industry

● Sand Casting Cores and Molds: Binder Jetting produces sand cores and molds for metal casting.

● Cost-Effective Tooling: It offers cost-effective tooling solutions for foundries.

5. Luxury Goods and Art

● Custom Jewelry: Binder Jetting allows jewelry designers to create intricate and personalized pieces.

● Artistic Sculptures: Artists use it to bring their creative visions to life.

6. Architecture and Construction

● Architectural Models: Binder Jetting produces detailed architectural models for visualization and presentations.

● Customized Building Components: It can create custom building elements with unique designs.

COMMENTS

- Be the first to share your thoughts!