Binder Jetting Meaning and Process

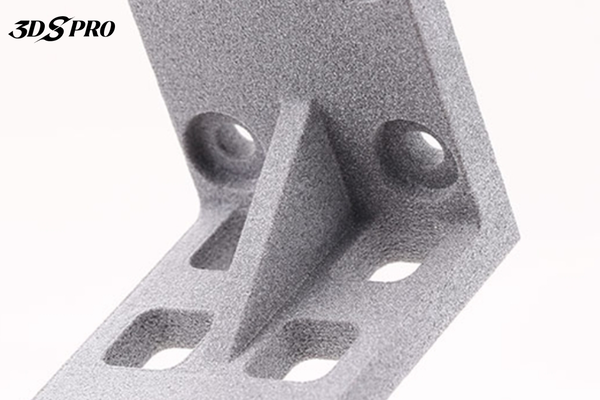

Binder Jetting creates objects layer by layer using a powder base material and a liquid binding agent. Binder Jetting does not rely on heat to fuse materials, so it can use a wide range of materials.

Binder Jetting Process

A thin layer of powder material is spread across the build platform. A print head then selectively deposits the liquid binder onto the powder layer, adhering the particles together to form a cross-section of the object. After each layer is printed, the build platform lowers slightly, and a new layer of powder is applied. This process repeats until the entire object is formed.

Image Source: ExOne

Binder Jetting Materials and Applications [1]

1. Stainless Steels

Binder jetting of stainless steels, particularly 316L, offers unique mechanical properties that are influenced by various process parameters and post-processing treatments.

Binder-jetted 316L stainless steel parts offer good tensile strength, compressive yield strength, and corrosion resistance, despite having larger grain size and higher porosity compared to Laser Powder Bed Fusion produced parts. They are suitable for a variety of applications including biomedical implants, automotive components, chemical processing equipment, aerospace components, custom tooling, heat exchangers and architectural elements.

2. Titanium Alloys

Binder jetting of titanium alloys, particularly Ti-6Al-4V (Ti64), offers unique mechanical properties that are influenced by various process parameters and post-processing treatments.

Binder-jetted Ti64 parts have excellent mechanical properties, including high strength, hardness, and wear resistance. Due to the light weight, biocompatibility, corrosion resistance and ability to produce complex geometries, binder-jetted Ti62 parts are suitable for a variety of applications ranging from aerospace components and biomedical implants to automotive parts, marine applications, chemical processing equipment, custom tools and heat exchangers.

3. Cobalt Alloys

Binder jetting of cobalt alloys, such as WC-Co (tungsten carbide-cobalt), offers unique mechanical properties that are influenced by the powder characteristics, binder type, and post-processing treatment.

By adjusting the cobalt content and optimizing the sintering conditions, the density, hardness, wear resistance, and fracture toughness of binder jetted WC-Co parts were improved. They are ideal for many applications, such as cutting tools, aerospace components, medical devices, wear-resistant coatings, energy sector parts, and custom tooling and molds due to their high strength, wear resistance, and ability to produce complex geometries.

4. Nickel-based Superalloys

Binder jetting of nickel-based superalloys offers unique mechanical properties that are influenced by the alloy composition, processing parameters, and post-processing treatments.

Binder-jetted nickel-based parts have high-temperature strength, excellent creep and corrosion resistance, high fatigue strength, and significant hardness. They can be used in aerospace components, gas turbines, chemical processing equipment, nuclear reactors, the oil and gas industry, heat exchangers, rocket propulsion and medical implants.ers, rocket propulsion, and medical implants.

5. Magnetic Shape Memory Alloys

Magnetic Shape Memory Alloys (MSMAs), particularly those based on Ni-Mn-Ga, exhibit unique mechanical properties when processed through binder jetting. The mechanical properties of binder-jetted MSMAs are influenced by several factors, including powder morphology, sintering conditions, and post-processing treatments.

The binder-jetted parts offers unique properties such as high strength, wear resistance, and the ability to undergo reversible shape changes in response to magnetic fields. They are suitable for applications such as actuators, sensors, medical devices and energy-efficient cooling systems.

6. Magnetic Materials

Binder jetting of magnetic materials, such as NdFeB and Fe-Si alloys, offers unique mechanical properties that are influenced by the powder characteristics, binder type, and post-processing treatments.

Binder jet magnetic parts feature high mechanical strength, intrinsic magnetic properties, and an isotropic microstructure. They are ideal for the manufacture of permanent magnets, soft magnetic components, medical devices, automotive parts and aerospace technology.

7. Copper

Binder jetting of copper offers unique mechanical properties that are influenced by various process parameters and post-processing treatments.

The mechanical properties of binder jetted copper parts, such as density and tensile strength, are highly dependent on their sintered density, with porosity and microstructure also playing a crucial role. Due to copper’s high thermal and electrical conductivity, the ability to achieve complex geometries, and improved overall performance through proper sintering and nanoparticle additives, these parts are ideal for applications such as thermal management systems, electrical components, filters, structural electronics, jewelry and decorative items, industrial parts, and rapid prototyping.

8. Ceramics

Binder jetting of ceramics offers unique mechanical properties that are influenced by various process parameters and post-processing treatments.

Binder jetted ceramic parts offer excellent mechanical properties such as high hardness, thermal conductivity, and resistance to wear, chemicals, and corrosion. These properties, combined with the ability to control porosity and microstructure through sintering, make binder jetted ceramics suitable for aerospace parts, biomedical implants, electronic components, filters and catalysts, tooling and wear parts, energy sector applications, optical components and artistic design.

9. Alumina

Binder jetting of alumina offers unique mechanical properties that are influenced by various process parameters and post-processing treatments.

Binder jetted alumina parts offer high density, excellent hardness, compressive strength, flexural strength, and superior thermal stability and wear resistance, making them ideal for a variety of high-performance applications, including biomedical implants, electrical insulators, wear-resistant components, thermal management systems, filters, catalyst supports, aerospace components, and customized tooling.

10. Porcelain

Binder jetting of porcelain offers unique mechanical properties that are influenced by various process parameters and post-processing treatments.

Binder jetted ceramic parts feature high hardness, excellent thermal stability and strong mechanical properties, with their density and microstructure significantly enhanced through post-processing steps such as sintering. They are suitable for various applications, including tableware and decorative items, architectural components, dental prosthetics, art and sculpture, industrial components, and filters and catalysts.

11. Metal Matrix Composites

Binder jetting of metal matrix composites offers unique mechanical properties that are influenced by the matrix material, reinforcement type, and processing parameters.

Due to the addition of ceramic reinforcements and an optimized sintering process, binder jetted metal matrix parts have increased density, hardness, strength, wear resistance, thermal properties, and stiffness compared to unreinforced metal. They are ideal for aerospace components, automotive parts, cutting tools, thermal management systems, armor applications, electronic packaging, sporting equipment and industrial wear parts where performance and durability are critical.

Resource:

[1] Amir Mostafaei, Amy M. Elliott, John E. Barnes, Fangzhou Li, Wenda Tan, Corson L. Cramer, Peeyush Nandwana, Markus Chmielus. " Binder jet 3D printing—Process parameters, materials, properties, modeling, and challenges" Available online 15 June 2020, Version of Record 29 April 2021, https://www.sciencedirect.com/science/article/pii/S0079642520300712#s0230.

COMMENTS

- Be the first to share your thoughts!