SLS 3D Printing Materials

Selective Laser Sintering (SLS) is a powerful 3D printing technology that uses a laser to sinter powdered material selectively, binding it together to create a solid structure. It’s used for both prototyping and small-batch production of functional plastic parts with complex geometries.

The choice of material significantly influences the mechanical properties and the final appearance of the printed part. Therefore, understanding the various SLS 3D printing materials is crucial for achieving the best results. Let’s explore the most commonly used materials in SLS 3D printing.

Nylon

Nylon for 3D printing, specifically Nylon PA 11 and PA 12 is one of the most popular materials used in SLS 3D printing. It’s known for its excellent mechanical properties, including strength, flexibility, and durability. Nylon is suitable for a wide range of applications, from functional prototypes to end-use parts. The surface of 3D-printed Nylon parts is slightly grainy, but it can be polished or painted for a smoother finish.

Nylon PA 11

Nylon PA 11 is derived from renewable resources and has superior impact resistance and elongation at break. It’s ideal for applications that require ductility and impact resistance, such as hinges or snap-fit assemblies.

Nylon PA 12

Nylon PA 12, on the other hand, offers excellent resistance to chemicals, heat, and UV light. It has high fatigue resistance, making it suitable for parts that need to withstand repetitive stresses, like gears or living hinges.

3DSPRO SLS Printed Nylon PA 12 Black Part

Glass-Filled Nylon

Glass-filled nylon is a composite material that combines nylon's versatility with the added strength and stiffness of embedded glass fibers. The unique combination results in a material that exhibits enhanced thermal and dimensional stability, making it an excellent choice for demanding applications in SLS 3D printing. However, it's important to note that the glass fibers also make the material more brittle, reducing its impact resistance and flexibility.

Glass-filled nylon is often used in applications that require parts to withstand high mechanical loads or harsh environmental conditions, including automotive components, industrial equipment, and high-performance consumer goods.

3DSPRO SLS Printed Nylon PA12 Glass-filled Part

Carbon-fiber Nylon

Carbon-fiber nylon is a composite material that blends nylon with microscopic carbon fibers. This results in a material that maintains the beneficial properties of nylon while also gaining the strength and rigidity of carbon fiber.

Carbon-fiber nylon has a high strength-to-weight ratio, excellent stiffness, and dimensional stability. The carbon fibers within the nylon matrix provide reinforcement, making the material stronger and more rigid than standard nylon. However, similar to Glass-filled nylon, the addition of carbon fibers can make the material more brittle and less resistant to impact.

Carbon-fiber nylon is suitable for applications that require high strength and rigidity, such as aerospace, automotive, and industrial parts. It’s also used in the production of drones, robotics, and other high-performance parts where weight and strength are critical.

Mineral-Filled Nylon

Mineral-filled nylon is a type of composite material used in SLS 3D printing. It combines the beneficial properties of nylon with the added strength and stiffness provided by mineral fillers. Mineral-filled nylon has enhanced thermal properties and dimensional stability. The mineral fillers within the nylon matrix provide reinforcement, increasing the material’s rigidity and heat deflection temperature.

However, it’s important to note that the addition of mineral fillers can reduce the material’s impact resistance and flexibility. The surface of 3D-printed Mineral-Filled Nylon parts is typically rougher than that of unfilled nylon, but it can be smoothed through post-processing techniques.

Mineral-filled nylon is often used in applications that require parts to withstand high temperatures or mechanical loads.

Aluminum-Filled Nylon

Aluminum-filled nylon is a composite material that combines nylon's beneficial properties with the added strength and thermal conductivity provided by aluminum fillers.

Aluminum-filled nylon has high thermal conductivity and improved mechanical properties. Compared to standard nylon, aluminum fillers are more resistant to deformation under mechanical stress and high temperatures. However, similar to other filled nylons, the addition of aluminum fillers can reduce the material's impact resistance and flexibility.

Due to its enhanced thermal properties and dimensional stability, Aluminum-Filled Nylon is often used in applications that require parts with high thermal conductivity and the ability to withstand high temperatures or mechanical loads.

PP

PP (Polypropylene) is a thermoplastic polymer widely used in many applications, including SLS 3D printing. It’s known for its excellent chemical resistance, elasticity, and toughness.

In 3D printing, PP plastic is valued for its durability and flexibility. Its low density makes it able to produce lightweight parts. Additionally, it has good resistance to fatigue, making it an excellent choice for creating living hinges and other flexible parts.

PP has excellent chemical resistance, making it suitable for containers that need to withstand corrosive chemicals. It also has good electrical insulation properties, which makes it useful in electronic components.

Furthermore, PP has a high melting point compared to many other plastics, making it ideal for applications that require heat resistance. However, it’s worth noting that while PP is tough and flexible, it’s not as strong or rigid as some other 3D printing materials.

PEEK

Polyetheretherketone, commonly known as PEEK, is a top-grade thermoplastic recognized for its excellent mechanical properties and chemical resistance. It's one of the most robust materials available for SLS 3D printing.

PEEK has excellent mechanical strength and stiffness, even at high temperatures. It also has excellent chemical resistance and can withstand a wide range of solvents and corrosive chemicals.

Furthermore, PEEK has excellent wear resistance, which makes it suitable for parts subject to friction or wear. It also has good electrical insulation properties, which make it useful in electronic components.

In the aerospace and automotive industries, PEEK is used for parts that need to withstand high temperatures and mechanical stress. Its biocompatibility and sterilization capabilities also make it the first choice in the medical industry for manufacturing surgical tools and implants.

PEKK

PEKK, short for Polyetherketoneketone, is gaining more popularity in the field of SLS 3D printing. It shares many properties with PEEK but offers additional benefits that make it stand out.

PEKK has excellent mechanical strength and stiffness, similar to PEEK. However, it has a higher glass transition temperature and melting point, which makes it more suitable for applications that require superior thermal resistance. In addition, PEKK offers excellent chemical resistance and commendable wear resistance, making it ideal for components subject to friction or wear.

TPU

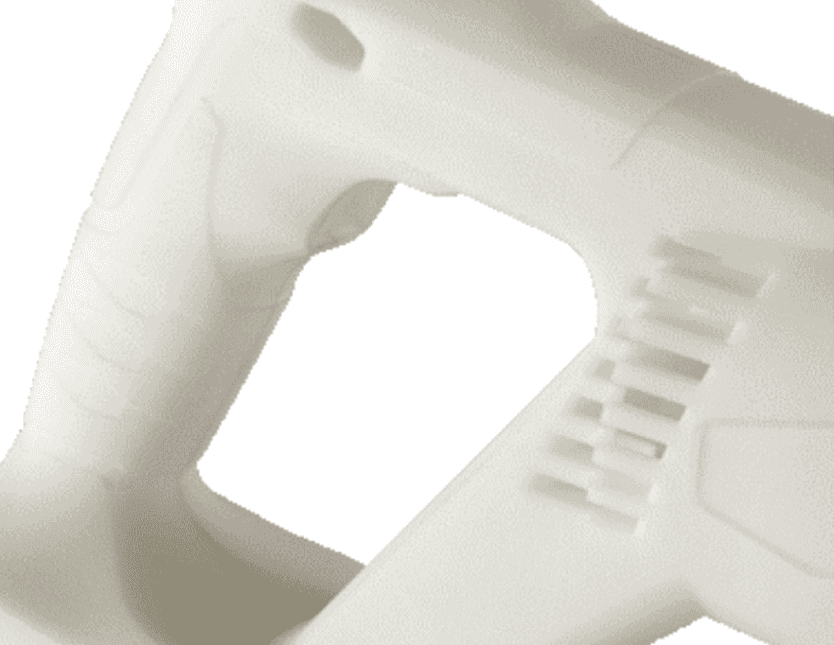

Thermoplastic Polyurethane, or TPU, is a type of flexible plastic widely used in SLS 3D printing. The elasticity and resistance to wear and tear of TPU make it a widely preferred material for numerous applications.

TPU combines the best properties of rubber and plastic. It’s highly elastic and flexible, yet it also offers excellent toughness and durability. TPU is resistant to oils, greases, and various solvents, which is ideal for parts that come into contact with such substances. In addition, TPU has excellent wear resistance, which makes it an ideal choice for parts that are prone to wear. It also has good low-temperature performance, retaining its flexibility even in cold conditions.

TPU is used in a wide range of applications. In the automotive industry, it’s used for parts like tubes, seals, and dampers. In the consumer goods industry, it’s used for items like shoe soles, watch bands, and phone cases. In the medical field, it’s used for devices like catheters and airway tubes.

TPE

TPE (Thermoplastic Elastomers) combines the beneficial properties of rubber with the processing advantages of thermoplastics. Due to their flexibility and durability, they are widely used in SLS 3D printing.

TPE materials are recognized for their elastic properties and their capacity to extend to moderate lengths and revert to their almost initial form, resulting in a longer lifespan and superior physical capabilities compared to other materials. Additionally, TPEs have excellent low-temperature performance, retaining their flexibility even in cold conditions. They also have good resistance to abrasion and good UV and ozone resistance, which makes them suitable for outdoor applications.

TPE is used in a wide range of applications. In the automotive industry, it’s used for parts like seals, gaskets, and plugs. In the consumer goods industry, it’s used for items like grips, handles, and over-molds. In the medical field, it’s used for devices like tubes, masks, and gloves.

Biomedical Materials

Biomedical materials used in SLS 3D printing are specially designed to meet the stringent requirements of the medical and healthcare industry.

Biomedical materials for SLS printing are used to manufacture custom implants, surgical guides, and medical devices. Some biomedical materials are bioresorbable, meaning they can be broken down and absorbed by the body over time. They are particularly useful for temporary implants that support tissue healing.

Besides, biomedical materials must have excellent mechanical properties to withstand the physiological stresses within the human body. They should also be sterilizable to ensure they do not carry any harmful bacteria or viruses.

Find More Selective Laser Sintering Materials at 3DSPRO

COMMENTS

- Be the first to share your thoughts!