The Rise of 3D Printed Custom Tech

For decades, consumer electronics had a one-size-fits-all model. Today, 3D printing is shattering that model, entering an age where gadgets are as individual as their owners. What started as a niche tool for rapid prototyping has become a manufacturing powerhouse, allowing brands — and even consumers — to create bespoke, high-performance tech.

During the early 2000s, 3D printing technology was restricted to labs and engineering teams, valued primarily for its speed in producing prototypes. Zoom ahead to 2025, and it’s transforming entire product lifecycles. Now, companies like Nike and Sonova use 3D scanning and 3D printing to manufacture sneakers and tailored hearing aids, respectively. In addition, brands such as Fairphone also use 3D printed elements to allow the customer to simply swap or upgrade parts of the phone.

Now, 3D printing can be the backbone of a tech revolution where customization and performance stand hand in hand.

Image Source: OPPO

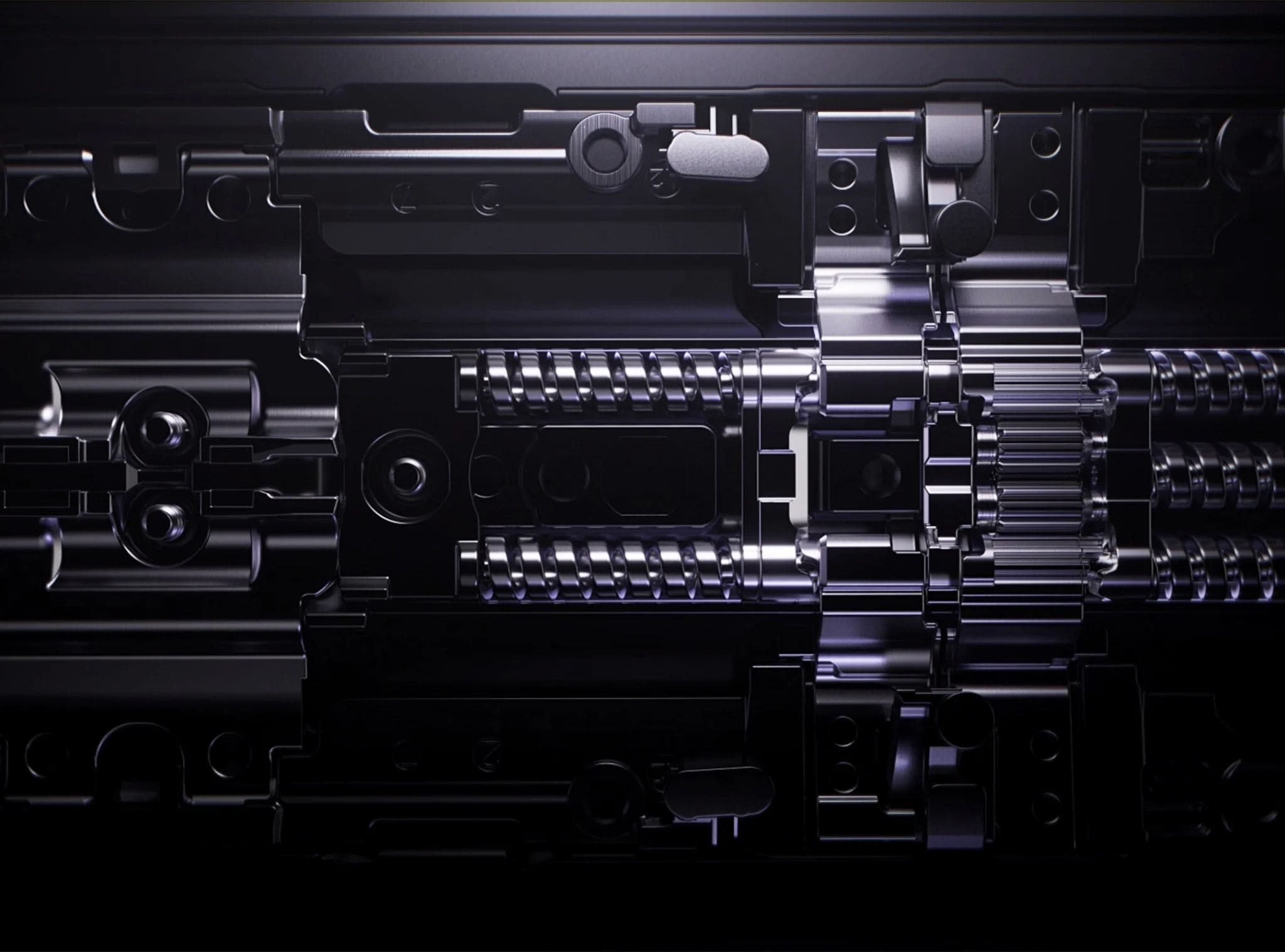

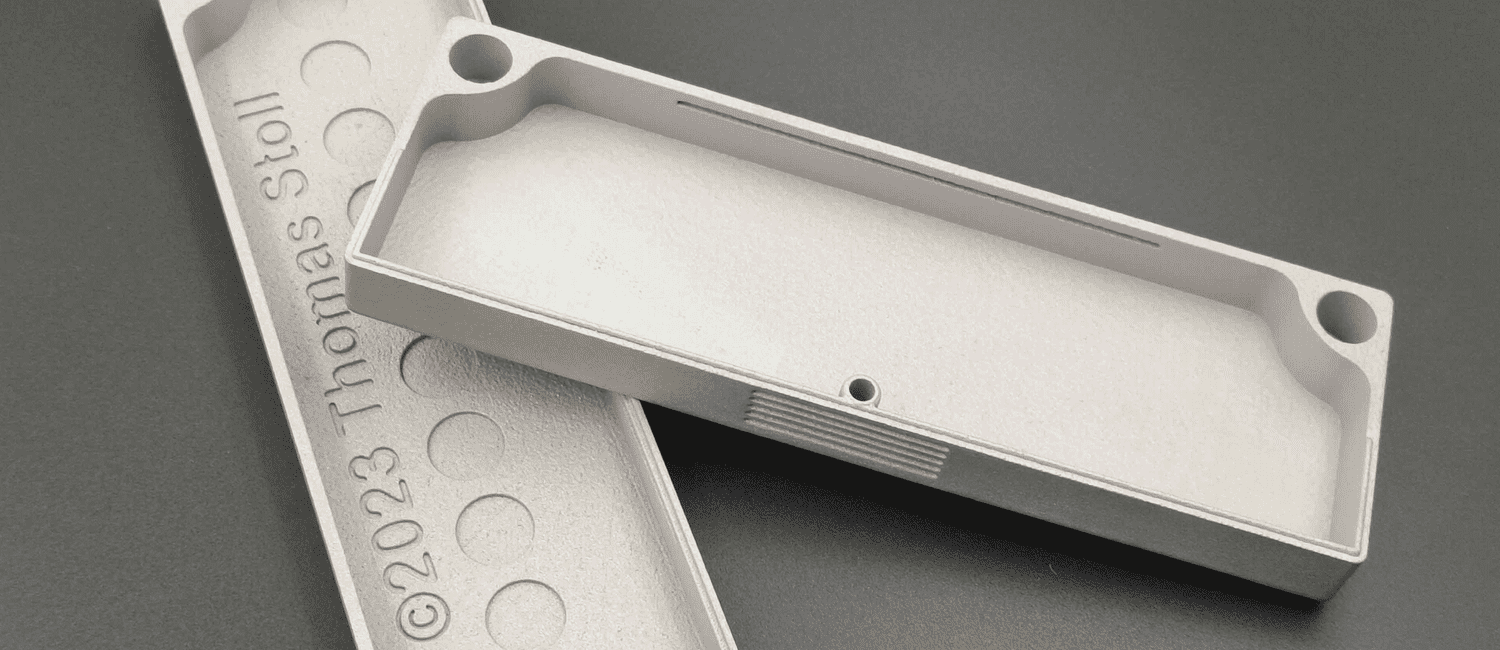

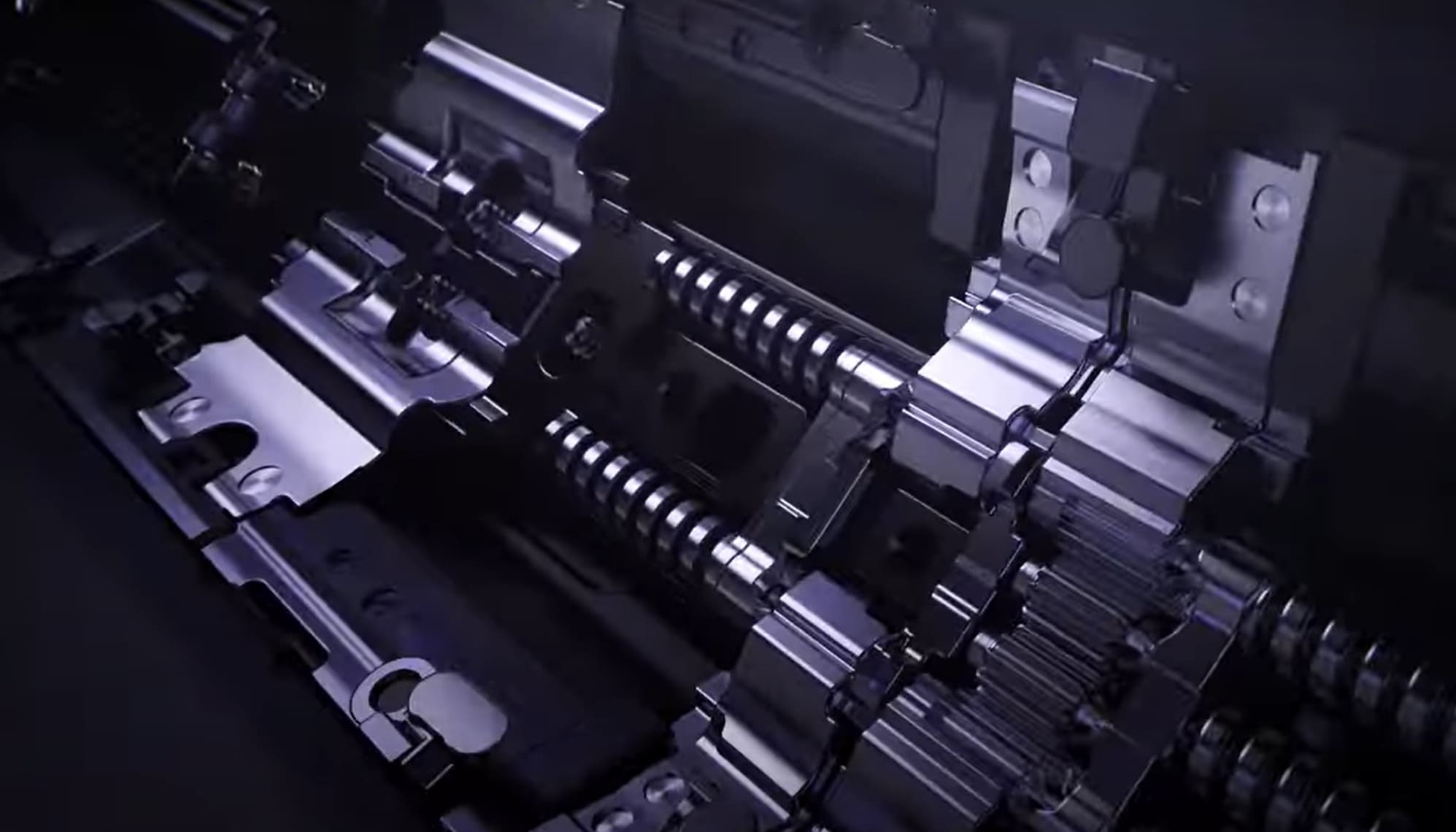

OPPO Find N5’s 3D Printed Titanium Hinge

OPPO has launched its latest foldable phone, the Find N5. And, today we are going to take a closer look at the OPPO Find N5’s Titanium Flexion Hinge, which is 3D printed from aerospace-grade Grade 5 titanium alloy—the same material used in Boeing 787 aircraft and Mars rovers—to achieve a perfect balance of lightness and durability.

The 3D printed titanium hinge achieved:

• 36% Higher Rigidity: Compared to its predecessor, the hinge’s structure was optimized using 3D printing to reduce thickness from 0.3mm to 0.15mm while enhancing strength.

• 26% Smaller Footprint: Despite its compact size, the hinge supports 100,000+ folds under extreme temperatures (-20°C to 50°C), earning TÜV Rheinland certification for reliability.

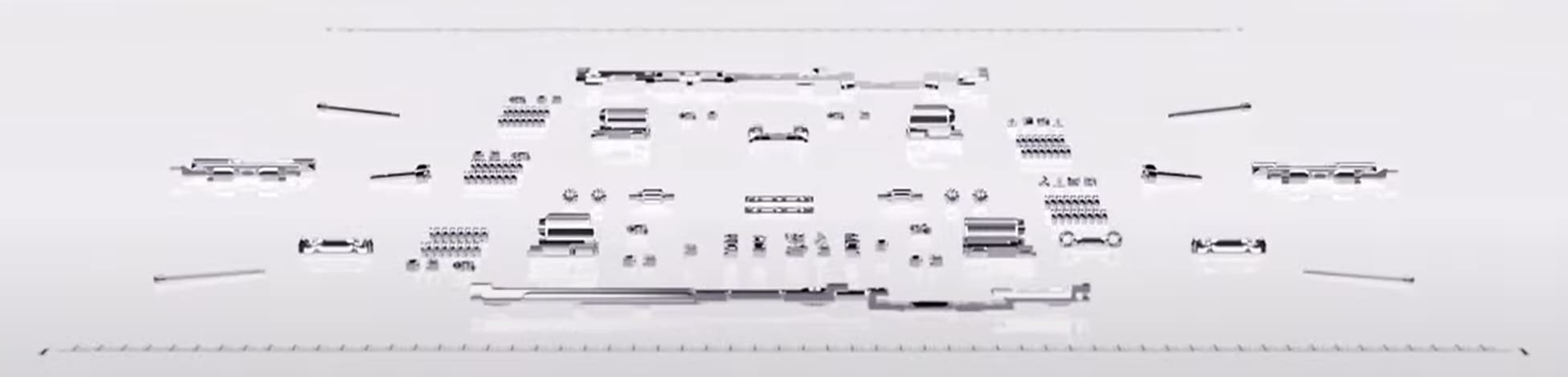

• Simplified Assembly: Traditional hinges require ~92 parts, but OPPO’s 3D printed design slashes this to just four components, reducing complexity and failure points.

OPPO produced the hinge using laser powder bed fusion (LPBF) technology. The 3D printed titanium hinge’s hollow, lattice-like structure cuts weight by 26% and resists deformation and corrosion. By leveraging 3D printing’s precision and material efficiency, OPPO has redefined what’s possible in foldable design.

Image Source: OPPO

Laser Powder Bed Fusion and Metal 3D Printed Titanium

LPBF is a metal 3D printing process that uses a high-power laser to selectively fuse fine metal powder into solid layers, building objects layer by layer. LPBF technology is capable of achieving resolutions as fine as 20–50 microns and working with metals like titanium, aluminum, and stainless steel to create intricate internal channels, lattices, and hollow structures unachievable with machining.

Selective laser melting is a specific LPBF technique where the laser fully melts metal powder to form dense, near-100% solid parts. It is ideal for high-performance applications in consumer electronics, aerospace, and medical devices.

3D Printed Titanium General Properties:

|

Property |

Detailed Information |

|

Strength-to-Weight Ratio |

Exceptionally high – Offers superior strength while remaining very lightweight. |

|

Corrosion Resistance |

Excellent – Naturally forms a protective oxide layer, making it highly resistant to corrosion. |

|

Biocompatibility |

Outstanding – Ideal for medical implants and applications where tissue compatibility is critical. |

|

Fatigue Resistance |

High – Capable of withstanding repeated cyclic stresses without significant degradation. |

|

Thermal Stability |

High – Retains strength and structural integrity over a broad temperature range. |

|

Processability |

Moderate – Well-suited to additive manufacturing but may require specific post‑processing for optimal surface quality. |

3D Printing’s Impact on Consumer Tech

3D printing is now a powerhouse redefining how consumer electronics are designed, produced, and experienced. By enabling flexibility, efficiency, and customization, the technology has a significant impact on consumer tech:

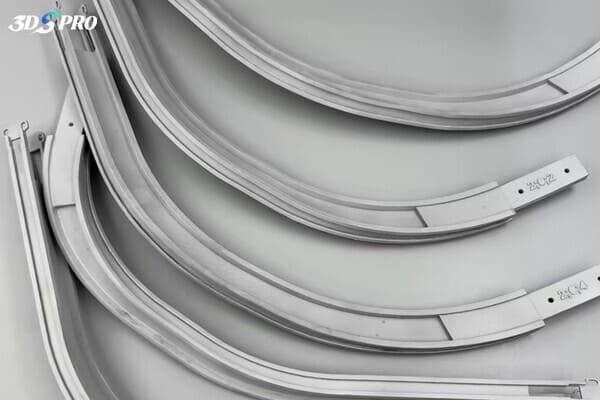

1. Design Freedom and Innovation

3D printing unlocks geometric possibilities, such as complex, lightweight structures (lattice), integrated functionality (cooling channels, and miniaturization (sensors).

2. Sustainability and Waste Reduction

Additive manufacturing aligns with the push for greener tech, as it enables material efficiency, localized production and a circular economy.

3. Democratizing Customization

3D printing empowers both brands and consumers to personalize tech, such as Adidas’ 4DFWD midsoles tailored to individual athletes’ biomechanics.

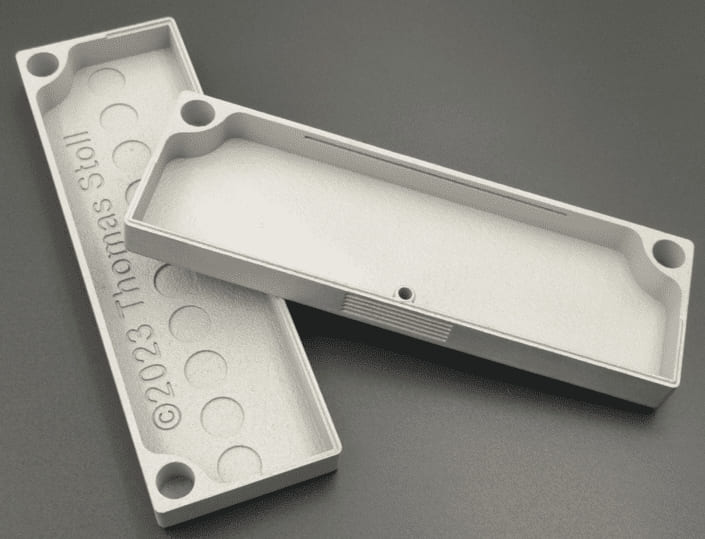

4. Accelerating Product Development

Rapid prototyping, small-batch production, and supply chain resilience are great advantages of 3D printing in consumer tech. For example, GoPro uses 3D printing to test camera housings in days, not months.

Image Source: OPPO

The Future of 3D Printing in Consumer Electronics

Advanced materials and multi-material printing will become standard. Next-gen materials such as:

• Self-Healing Polymers: Gadgets that repair minor cracks or scratches autonomously (e.g., smartphone casings).

• Conductive Inks and Flexible Circuits: Fully 3D-printed electronics, like foldable displays with embedded sensors (Samsung is rumored to be exploring this).

• Biodegradable Hybrids: Compostable materials blended with recycled metals for eco-friendly wearables.

Besides, multi-material machines like Stratasys J55 will create devices in a single run—combining rigid frames, soft-touch grips, and transparent components (think about seamless AR glasses).

Moreover, AI-driven design and generative engineering will thrive with 3D printing. AI will revolutionize how products are conceived. Tools like nTopology will auto-generate lightweight, ultra-efficient structures. AI algorithms will use biometric data to design custom-fit earbuds or smartwatch bands tailored to individual users.

The future of 3D printing in consumer electronics is about redefining creativity, sustainability, and ownership. The question isn’t if 3D printing will transform tech—it’s how soon we’ll embrace its limitless potential.

COMMENTS

- Be the first to share your thoughts!