What is metal 3D printing?

Metal 3D printing, also known as metal additive manufacturing, creates metal parts or objects by depositing layers of metal material on top of each other. Unlike traditional manufacturing methods that rely on cutting, drilling, or molding, metal 3D printing builds the part from scratch, layer by layer, using a digital model as a guide, which allows for greater design freedom, complexity, customization, and reduced material waste and production time.

Metal 3D printing can create various metal parts, such as aerospace components, medical implants, automotive parts, jewelry, and more. Metal 3D printing can also repair or enhance existing metal parts, such as adding features, filling gaps, or restoring worn surfaces. Metal 3D printing can produce stronger, lighter, or more durable parts than conventional metal parts, depending on the material and process used.

Types of Metal 3D Printing

Metal 3D printing is a broad term that encompasses various methods of creating metal parts using additive manufacturing. Here are some of the most common types of metal 3D printing and their characteristics:

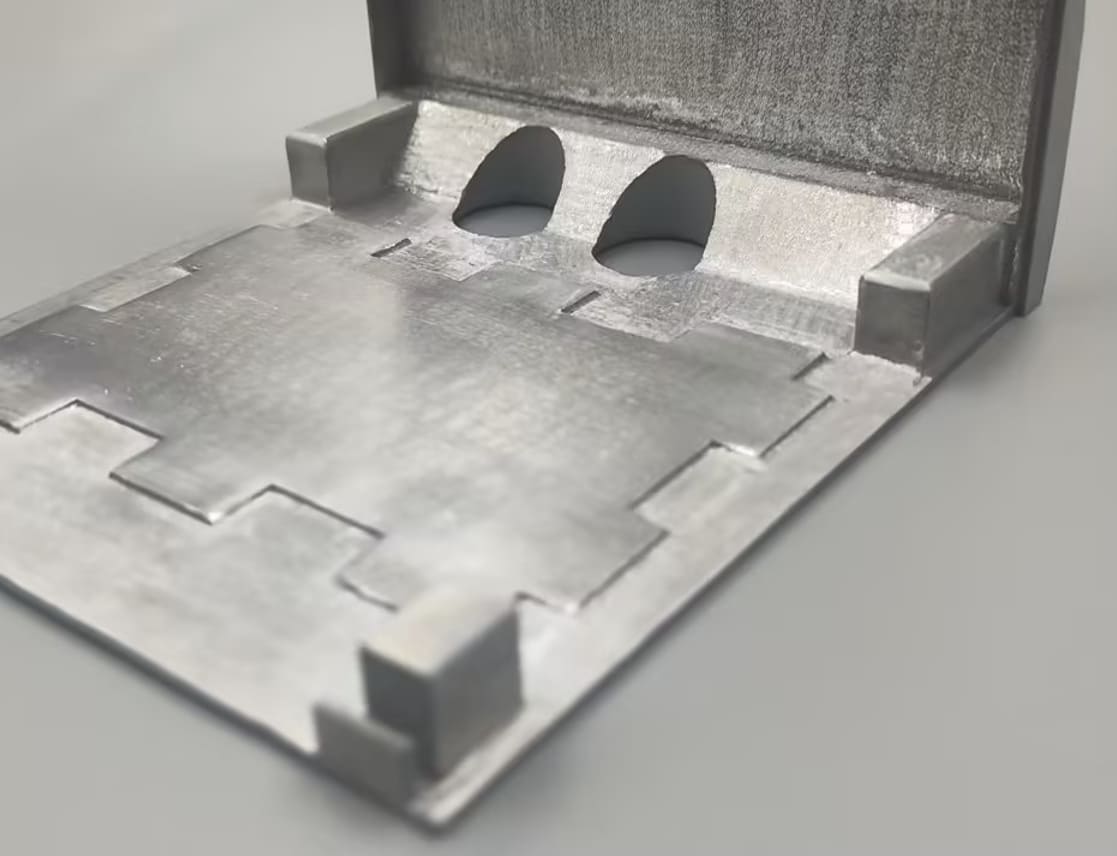

Metal Binder Jetting

Metal Binder Jetting uses a print head to deposit a liquid binder onto a bed of metal powder, layer by layer, to form the part. The binder acts as a glue that holds the powder together. After printing, the part is cured in an oven and sintered in a furnace to remove the binder and fuse the metal particles. Metal binder jetting can produce parts with high resolution and complex geometries, but they may have lower strength and density than other methods.

Image Source: AMFG

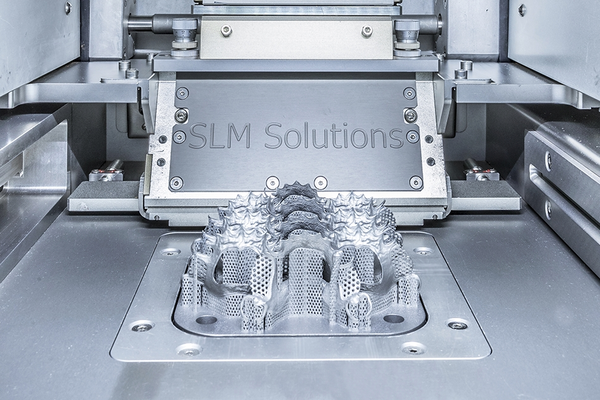

SLM (Selective Laser Melting) and DMLS (Direct Metal Laser Sintering)

SLM and DMLS use a laser to selectively melt and fuse metal powder on a build platform, layer by layer, to form the part. The difference between SLM and DMLS is that SLM fully melts the metal, while DMLS only partially melts it. Both processes can produce parts with high density and strength, but they may have high residual stresses and require post-processing.

EBM (Electron Beam Melting)

EBM uses an electron beam to selectively melt and fuse metal powder on a build platform, layer by layer, to form the part. The process occurs in a vacuum chamber and at high temperatures, reducing the risk of oxidation and distortion. EBM can produce high density and strength parts but may have a rough surface finish and require post-processing.

Image Source: 3Dnatives

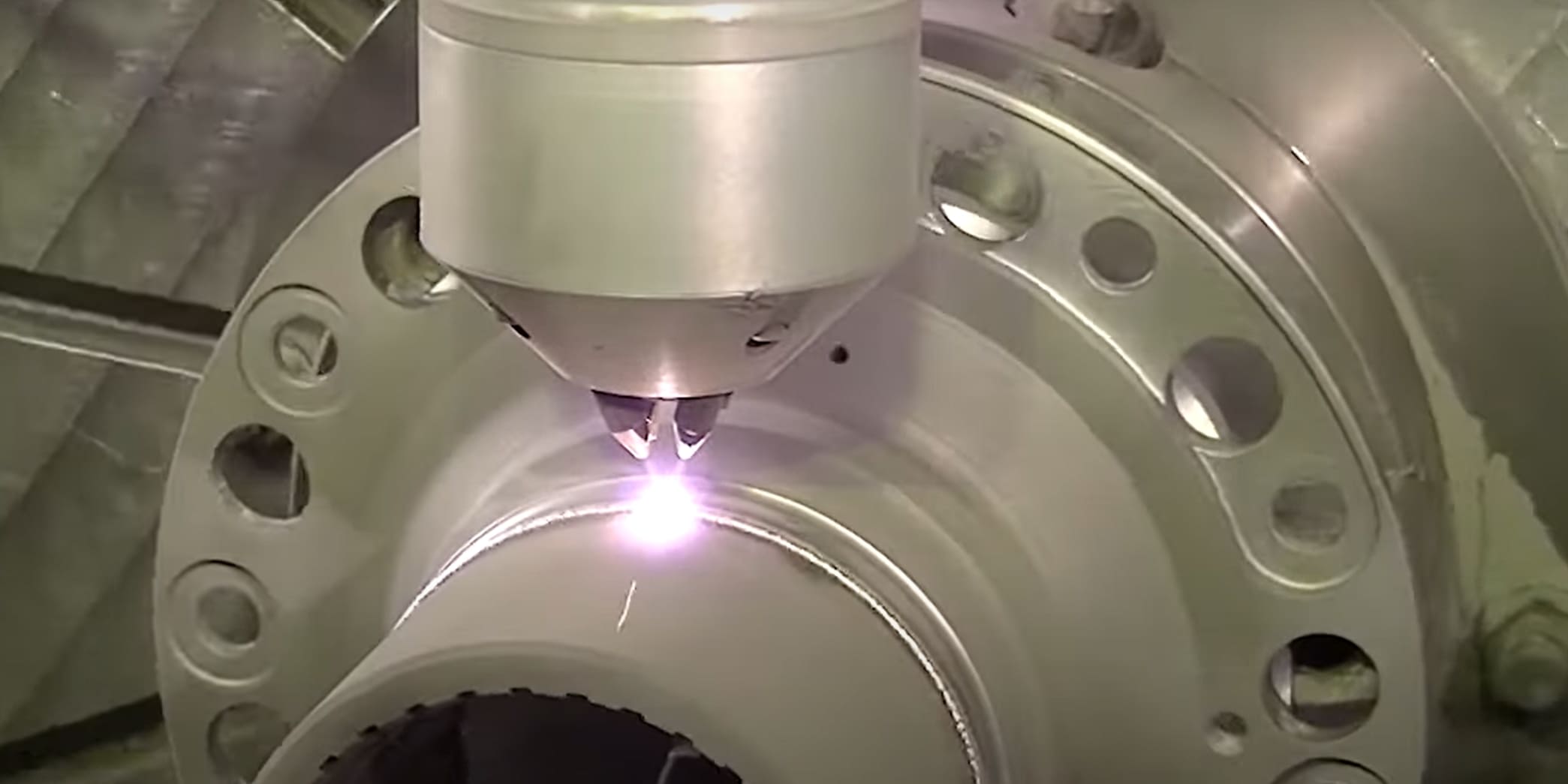

DED (Directed Energy Deposition)

DED uses a nozzle to deposit metal powder or wire into a focused energy source, such as a laser or an electron beam, which melts and fuses the material as it is deposited. The nozzle can move in multiple directions, allowing for freeform and repair applications. DED can produce parts with high deposition rates and large sizes, but they may have low resolution and require post-processing.

Image Source: 3Dnatives

LENS (Laser Engineered Net Shaping)

LENS uses a laser to melt and fuse metal powder or wire, layer by layer, to form the part. The nozzle that delivers the material can move in multiple directions, allowing for freeform and repair applications. LENS can produce highly-resolution parts and complex geometries but may have lower strength and density than other methods.

Image Source: OPTOMEC

LOM (Laminated Object Manufacturing)

LOM uses a laser to cut and bond thin sheets of metal foil, layer by layer, to form the part. The process is similar to paper-based 3D printing but with metal foils instead of paper. LOM can produce parts with low cost and high speed, but they may have low strength and require post-processing.

UAM (Ultrasonic Additive Manufacturing)

UAM uses ultrasonic vibrations to bond metal foils or wires, layer by layer, to form the part. The process does not require high temperatures or melting, which reduces the risk of distortion and oxidation. UAM can produce parts with low cost and high speed, but they may have low strength and require post-processing.

How does metal 3D printing work?

Metal 3D printing is a term that covers several additive manufacturing processes that create metal parts from metal powder or wire. The main difference between these processes is the source of energy that melts or fuses the metal material, such as a laser, an electron beam, or an ultrasonic vibration.

The basic steps of metal 3D printing are:

1. A digital 3D model of the part is sliced into thin layers by a software program (slicer).

2. A metal 3D printer deposits a layer of metal powder or wire on a build platform or a substrate.

3. A high-power laser, an electron beam, or an ultrasonic vibration selectively melts or fuses the metal material according to the cross-section of the layer.

4. The build platform or the substrate is lowered, and a new layer of metal material is deposited on top of the previous layer.

5. The process is repeated until the part is completed.

6. The part is removed from the printer and undergoes post-processing, such as heat treatment, machining, or polishing.

Based on the type of metal 3D printing process and metal materials, the part may have different characteristics, such as density, strength, surface finish, accuracy, and complexity.

Materials for Metal 3D Printing

Metal 3D printing creates metal objects by depositing layers of molten or powdered metal. Metal 3D printing materials are the metals that can be used for this process. The choice of metal 3D printing material depends on factors such as part complexity, mechanical properties, surface finish, cost, and availability. Some of the most common and popular materials for metal 3D printing are:

Aluminum: Aluminum is a lightweight, strong metal with high corrosion resistance, biocompatibility, and thermal stability. Aluminum is widely used for metal 3D printing, especially for aerospace, automotive, and medical applications. Aluminum powder for 3D printing comes in various grades and alloys, such as AlSi7Mg, AlSi10Mg, AlSi12, and AlSi9Cu3. Aluminum can be printed with various metal 3D printing processes, such as powder bed fusion, binder jetting, metal extrusion, and wire arc additive manufacturing. Aluminum can produce parts with low weight, high strength, and good conductivity, but it may also have lower accuracy, rougher surface finish, and higher material cost than other metals.

Stainless steel: Stainless steel is a family of iron-based alloys that contain chromium, nickel, and other elements that enhance their corrosion resistance, strength, and aesthetic appearance. Stainless steel is widely used for metal 3D printing, especially for parts that require high resolution, complex geometries, and good surface finish. Stainless steel powder for 3D printing comes in various grades and alloys, such as 316L, 304L, 17-4 PH, and 15-5 PH.

Tool steels: Tool steels are a family of iron-based alloys with high levels of carbon and other elements that form hard carbides, such as tungsten, chromium, vanadium, and molybdenum. Tool steels offer excellent hardness, wear resistance, and high-temperature strength, making them ideal for metal 3D printing of molds, stamps, and cutting tools. Tool steel powder for 3D printing comes in various grades and alloys, such as D2, M2, H13, H11, MS1, and 1.2709.

Titanium: Titanium is a lightweight, strong metal with high corrosion resistance, biocompatibility, and thermal stability. Titanium is the most-used metal in additive manufacturing, especially for aerospace, medical, and automotive applications. Titanium powder for 3D printing comes in various grades and alloys, such as Ti6Al4V, Ti6Al4V ELI, Ti64, and CP Ti.

Inconel: Inconel is a family of nickel-based alloys that contain chromium, iron, and other elements that enhance their high-temperature performance, oxidation resistance, and creep resistance. Inconel is widely used for metal 3D printing of parts that operate in harsh environments, such as jet engines, gas turbines, and chemical plants. Inconel powder for 3D printing comes in various grades and alloys, such as Inconel 625, Inconel 718, and Inconel 939.

Metal 3D Printing Post-processing

Metal 3D printing post-processing is the process of improving the quality and functionality of metal 3D printed parts after they are removed from the printer. Post-processing methods include the removal of support structures, which are often necessary during printing to uphold complex geometries, and surface finishing techniques, such as tumbling or polishing, to achieve the desired surface smoothness. Post-processing can also enhance the mechanical properties and performance of metal 3D-printed parts by applying heat treatments, coatings, or welding methods.

Support Removal

Support removal removes the support structures attached to the part during printing. Support removal can be done manually with hand tools, such as pliers or cutters, or automatically with machines, such as wire EDM or band saw. Support removal can reduce the weight and improve the appearance of the part, but it may also cause damage or deformation if not done carefully.

Tumbling

Tumbling is placing the part in a rotating barrel filled with abrasive media, such as ceramic or steel balls, and applying vibration or centrifugal force. Tumbling can smooth the surface and remove sharp edges or burrs from the part, but it may also reduce the accuracy or detail of the part.

Spray Painting

Spray painting involves applying a layer of paint or lacquer to the part's surface using a spray gun or an aerosol can, which improves the aesthetic and corrosion resistance of the part. Still, it may also affect its dimensional accuracy or mechanical properties.

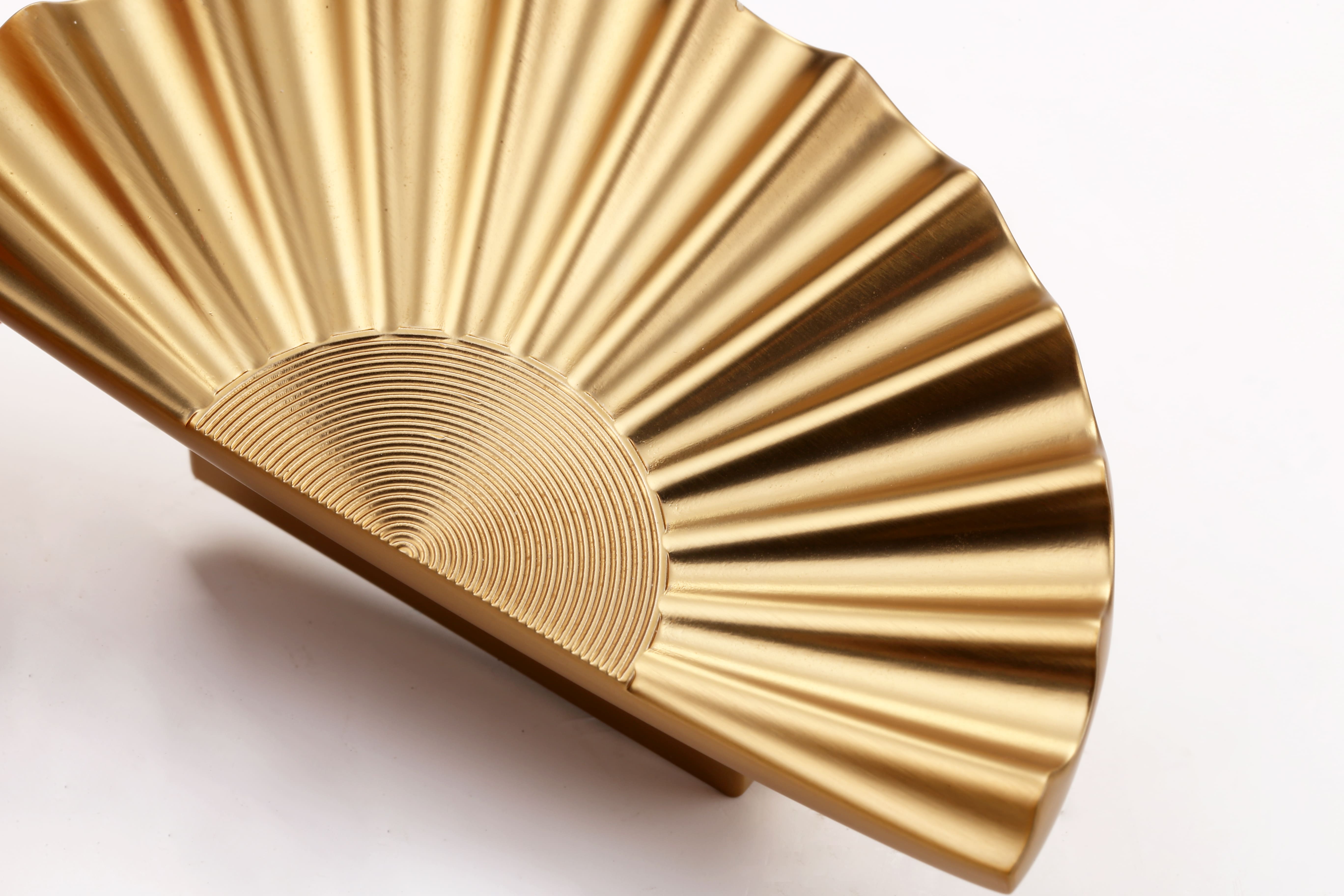

Electroplating

Electroplating immerses the part in an electrolytic solution and applies an electric current to deposit a thin layer of metal, such as gold or silver, onto the part's surface. Electroplating enhances the part's appearance, conductivity, and wear resistance but may introduce defects or stresses.

Here are the common post-processing processes of metal 3D printing, with their pros and cons.

Annealing

Annealing is to heat the part to a high temperature and then cool it slowly to reduce the residual stresses and improve the ductility and toughness of the part. Annealing improves the microstructure and homogeneity of the part, but it may cause distortion or oxidation.

Anodizing

Anodizing immerses the part in an acidic solution and applies an electric current to form a thin layer of oxide, such as aluminum oxide, on the part's surface. Anodizing can increase the hardness, corrosion resistance, and color of the part, but it may reduce its conductivity or fatigue strength.

Stress Relieving Treatment

It involves heating the part to a moderate temperature and then cooling it rapidly to relieve the residual stresses and prevent cracking or warping of the part. Stress-relieving treatment improves the dimensional stability and performance of the part, but it may affect the hardness or microstructure of the part.

Hardening

Hardening heats the part to a high temperature and then cools it rapidly to increase the hardness and strength of the part. Hardening can also improve the part's wear resistance and fatigue life, but it may reduce the ductility or toughness of the part.

Electropolishing

Electropolishing immerses the part in an electrolytic solution and applies an electric current to remove a thin layer of metal from the part's surface. Electropolishing smoothes the surface and removes impurities or defects from the part, but it may alter the dimensions or shape of the part.

Cold welding

Cold welding joins two metal parts by applying pressure and plastic deformation without using heat or filler material. Cold welding creates strong and seamless bonds between metal parts but may require high force or special equipment.

Metal 3D Printing VS CNC Machining

Metal 3D printing and CNC machining are two manufacturing technologies that produce metal parts with various characteristics and applications. Both methods have advantages and disadvantages, depending on part complexity, quantity, material, accuracy, surface finish, cost, and turnaround time. Here are some main differences and similarities between metal 3D printing and CNC machining.

Process

Metal 3D printing is an additive process that builds parts layer by layer from metal powder or wire, using a laser, an electron beam, or an ultrasonic vibration to melt or fuse the material. CNC machining is a subtractive process that removes material from a solid block, using rotating tools and cutters to shape the part.

Design Freedom

Metal 3D printing offers more design freedom and flexibility than CNC machining, as it can create complex geometries, internal features, and organic shapes that are difficult or impossible to achieve with CNC machining. However, metal 3D printing may also require support structures to uphold overhanging or hollow features, which must be removed and post-processed after printing.

Material Selection

Metal 3D printing is limited by the availability and compatibility of metal powders or wires, which are more expensive and less common than metal blocks. However, metal 3D printing can also create custom alloys or gradient materials that are impossible with CNC machining. CNC machining offers a wider range of material selection than metal 3D printing, as it can work with almost any type of metal, such as aluminum, steel, titanium, brass, copper, and more.

Accuracy and Surface Finish

CNC machining offers better accuracy and surface finish than metal 3D printing, as it can achieve tight tolerances and smooth surfaces without additional processing. Metal 3D printing may have lower resolution and rougher surface finish due to the layer-by-layer deposition and the heat-induced distortion or warping. Metal 3D printed parts often require post-processing, such as sandblasting, polishing, or heat treatment, to improve their quality and performance.

Cost and Turnaround Time

The cost and turnaround time of metal 3D printing and CNC machining depend on factors such as part size, complexity, quantity, material, and post-processing. In general, metal 3D printing has lower setup costs and faster turnaround time than CNC machining for small batches of complex parts, as it does not require part-specific tools or fixtures. However, metal 3D printing has higher material costs and slower production rates than CNC machining for large batches of simple parts, as printing each layer consumes more energy and time.

Where can I find custom metal 3D printing?

If you are looking for a reliable and affordable metal 3D printing service, you can trust 3DSPRO. Whether you need a single prototype or a large batch of production parts, you can find 3DSPRO's metal 3D printing service that suits your needs and budget.

3DSPRO is a platform that integrates 3D printing services and 3D+ solutions. We offer online metal 3D printing services with the lowest general cost, high quality, and fast turnaround. We also offer customized services based on your model, such as surface finishes, heat treatments, coatings, or welding. You can upload your 3D model for a free instant quote and manufacturability suggestions. We can help you accelerate your innovation with comprehensive 3D printing solutions.

COMMENTS

- Be the first to share your thoughts!