We Used 316L Stainless Steel to Manufacture Food Storage for Dates

Over the past few months, we have been working closely with NUA and Lazy Snail on a food storage project (read the full case study here), specifically dates packaging. We manufactured the metal components of three types of dates packaging, all made from 316L stainless steel, a perfectly food-safe material.

Throughout the project, from prototype to mass production, 316L was the material used, and even the manufacturing process was adjusted several times. We successfully created the Dunes and the Stem.

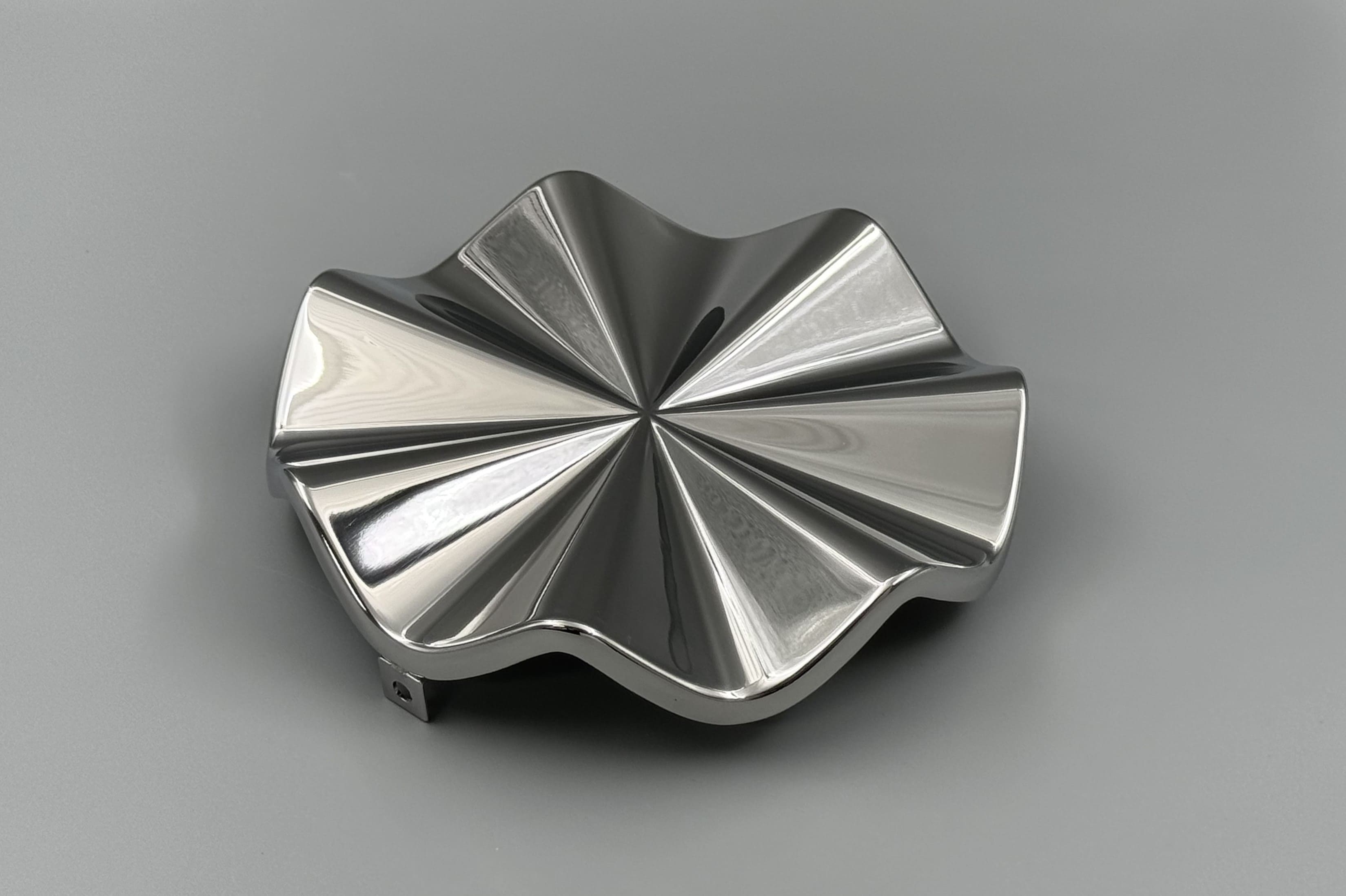

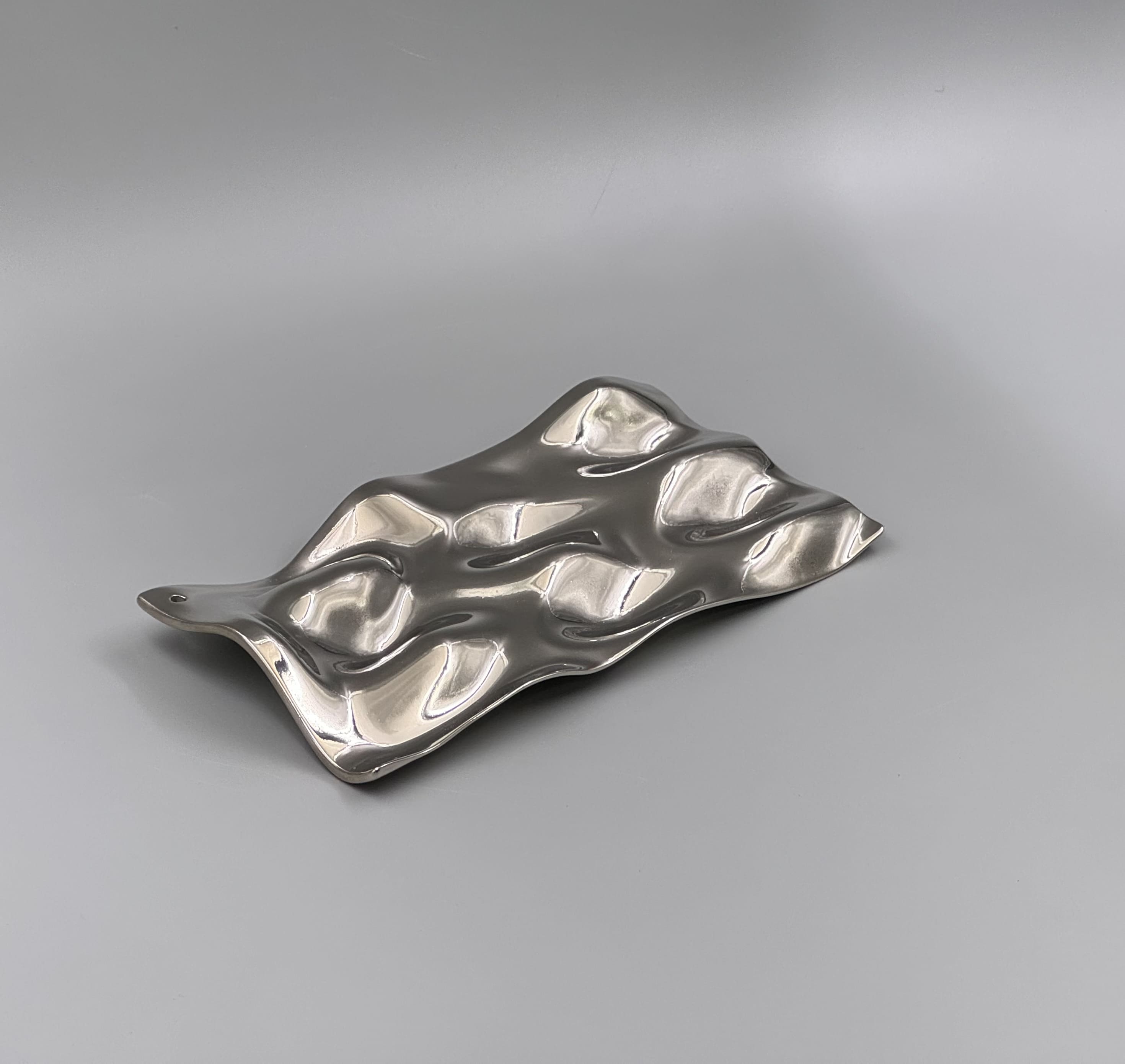

3D printing 316L stainless steel was full of challenges, primarily due to the complex geometry of the design. The Dunes have a flat large surface with irregular ripples; the Stem have multiple sharp angles. So, we started prototyping to see if metal 3D printing and post-polishing were feasible to create an amazing package. Unfortunately, even though we successfully made and polished the 316L part, there were still many imperfections in the surface finish, mainly due to the high density of the 3D printed 316L metal. Check out the 3D printed 316L Dunes prototype:

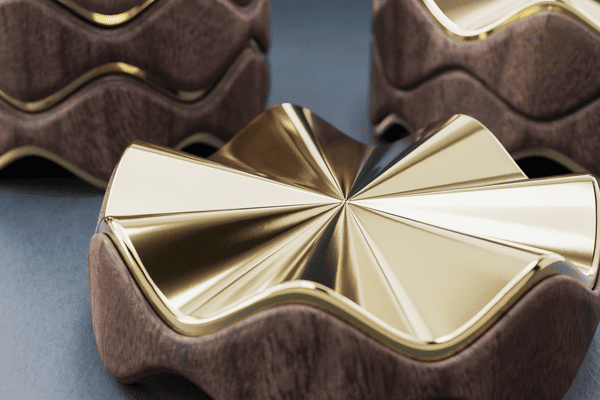

Metal 3D printing 316L was not perfect enough for us, so we turned to conventional manufacturing, including stamping and CNC machining. This time, we also upgraded the 316L to 8K 316L sheet! Furthermore, the packaging surface is coated with a gold-colored titanium by using PVD coating. We made a total of 150 pieces for this first small batch:

So, why are we so obsessed with 316L for this project? We have to say, 316L stainless steel is the best choice for food storage!

What is 316L stainless steel?

316L stainless steel is a high-grade, corrosion-resistant alloy known for its exceptional durability and versatility. It is mainly composed of iron, chromium and nickel, and also contains molybdenum.

316L stands out for its exceptional resistance to chlorides and acidic environments. The “L” indicates its lower carbon content, which enhances its resistance to sensitization and pitting corrosion. Therefore, 316L is an ideal choice for food storage and processing applications.

316L stainless steel maintains its structural integrity and sanitary standards even under the most demanding conditions.

Why can 316L stainless steel be used for food storage?

1. Corrosion Resistance

316L stainless steel has exceptional resistance to corrosion, helping to prevent rust and contamination and ensuring that the food remains safe for consumption over time.

2. Durability and Longevity

316L stainless steel withstands the wear and tear of everyday use. Its high tensile strength and toughness ensure that containers and storage units are durable.

3. Hygienic Properties

316L stainless steel has a non-porous surface, which makes it easy to clean and sanitize. This is essential for food storage as it prevents the accumulation of bacteria, mold and other pathogens, ensuring the storage environment remains sanitary and food is kept safe.

4. Resistance to Temperature

316L stainless steel can withstand a wide range of temperatures, from freezing conditions to hot environments, making it ideal for a variety of food storage applications.

5. Chemical Compatibility

316L has good resistance to a wide range of chemicals and acids present in food. This is essential to maintaining the purity and safety of the food being stored.

6. Structural Integrity

316L stainless steel maintains its structural integrity under pressure and load, making it suitable for storing large amounts of food without risk of deformation or cracking.

7. Aesthetic Appeal

In addition to its functional benefits, 316L stainless steel also offers a polished, sleek appearance. This makes it an attractive choice for commercial and home food storage solutions.

8. Environmental Sustainability

316L stainless steel is fully recyclable. Its long life and recyclability make it an environmentally friendly choice.

More Applications of 316L in Food Storage

1. Food Processing Equipment

316L stainless steel is commonly used in the manufacture of food processing equipment such as mixers, blenders, and conveyors. Its corrosion resistance and non-reactive nature ensure that the food remains uncontaminated during processing.

2. Storage Tanks and Silos

Large tanks and silos used to store liquids and bulk foods are often made from 316L stainless steel. This is due to the material's durability and ability to withstand harsh conditions, including exposure to acids and cleaning agents.

3. Refrigeration Units

Commercial and industrial refrigeration equipment, including cold rooms and freezers, frequently uses 316L stainless steel. Its excellent resistance to temperature fluctuations and corrosion ensures that refrigeration equipment operates efficiently and maintains the hygiene standards required for food storage.

4. Kitchen and Culinary Tools

Professional kitchen and culinary tools, such as knives, utensils, and preparation surfaces, are made from 316L stainless steel because of the material's strength, hygienic properties, and resistance to staining and corrosion.

5. Beverage Storage and Dispensing

316L stainless steel is used in beverage storage containers, such as kegs and brewing vessels, as well as in dispensing systems. Its non-reactive nature ensures that beverages retain their original flavor and quality, free from any contamination.

Properties Cheat Sheet of 3D Printing 316L Stainless Steel

Here are the properties of 3D printed 316L stainless steel at 3DSPRO:

| Tensile Strength | Elongation at Break | Yield Strength | Elastic Modulus | Hardness | Roughness Ra |

| 530MPa | 50% | 340MPa | 180GPa | 200 HV | 15µm |

COMMENTS

- Be the first to share your thoughts!