In recent years, 3D printing has emerged as a revolutionary technology that has transformed various industries, from manufacturing and healthcare to design and education. This article delves into the advantages and disadvantages of 3D printing, highlighting its potential benefits and potential limitations. By understanding the pros and cons of this technology, we can gain valuable insights into its applications and make informed decisions about its implementation.

Advantages of 3D Printing

1. Design Freedom and Customization

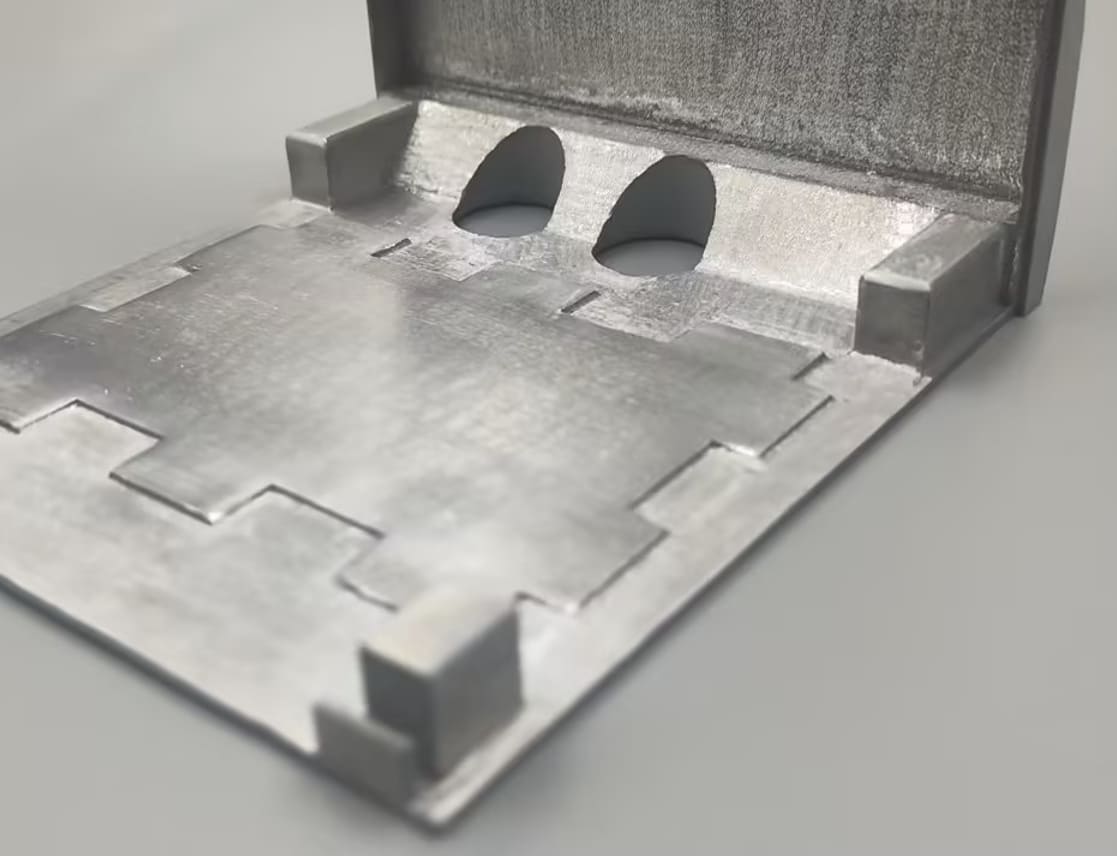

One of the most significant advantages of 3D printing is the ability to create complex and customized designs. Unlike traditional manufacturing methods, which are often limited by molds and tooling, 3D printing allows for intricate geometries and unique structures. This design freedom enables customization, empowering industries like healthcare to produce personalized medical devices, prosthetics, and implants tailored to individual patients' needs.

2. Rapid Prototyping and Iteration

3D printing accelerates the product development process by facilitating rapid prototyping and iteration. Designers and engineers can quickly create physical prototypes, test them, identify design flaws, and make necessary modifications. This iterative approach saves time, reduces costs, and enhances the overall product development cycle.

3. Cost-Effective Manufacturing

For low-volume production runs, 3D printing offers cost advantages over traditional manufacturing methods. It eliminates the need for complex tooling and allows for on-demand production, reducing inventory costs. Additionally, the ability to consolidate multiple parts into a single 3D-printed component can simplify assembly processes and further reduce costs.

Disadvantages of 3D Printing

1. Limited Material Selection

While the range of available materials for 3D printing is continually expanding, it is still limited compared to traditional manufacturing methods. Some materials commonly used in traditional manufacturing, such as certain metals and high-performance alloys, may not be easily compatible with current 3D printing technologies. Additionally, material properties may not always match those achieved through conventional processes, limiting the suitability for specific applications.

2. Production Scale

Although 3D printing is a versatile technology, it typically lags behind traditional manufacturing, such as injection molding, in terms of production speed and therefore production scale. Depending on the complexity and size of the object, the layer-by-layer additive manufacturing process can be time-consuming. Large-scale production therefore may not be or cost-effective with current 3D printing capabilities.

3. Surface Quality and Finishing

3D-printed parts may exhibit visible layer lines and surface imperfections, requiring additional post-processing steps to achieve desired aesthetics and functionality. Sanding, polishing, or coating processes may be necessary, adding time and cost to the overall production process. 3DSPRO provides 3D Plus Solutions to help our innovators to achieve better surface results.

4. Equipment and Operational Costs

Acquiring and maintaining 3D printing equipment can be a significant investment. The cost of high-quality 3D printers, along with the materials and software required, can be prohibitive for some businesses. Furthermore, expertise in operating and troubleshooting 3D printers is essential, which may necessitate additional training or hiring skilled personnel.

As with any technology, 3D printing presents a set of advantages and disadvantages. The ability to create complex designs, facilitate rapid prototyping, and cost-effectively manufacture custom parts are among the remarkable benefits. However, limitations in material selection, production speed, surface quality, and equipment costs are important considerations. While 3D printing continues to evolve and improve, it is crucial to evaluate its suitability for specific applications and weigh the advantages against the potential drawbacks. As the technology progresses, addressing the current limitations will contribute to further adoption and utilization of 3D printing across industries, unlocking its full potential in the realm of additive manufacturing. With the help of 3DSPRO, you can always try 3D Printing in a risk free and hassle free way: give us your CAD files and we will do the rest for you.

COMMENTS

- Be the first to share your thoughts!