A footwear startup, Syntilay, is making strides in the shoe industry by utilizing artificial intelligence (AI) and 3D printing technology to create high-quality, custom-made shoes.

Syntilay, founded by Ben Weiss and supported by Joe Foster of Reebok, employs AI technology from companies like MidJourney and Vizcom to generate intricate shoe designs and shapes.

The process starts with AI creating initial concepts, which are then developed by human designers and translated into 3D models by AI. With the help of these models, the shoes are FDM 3D printed using durable materials such as thermoplastic polyurethane (TPU) to ensure comfort and sustainability.

With their ability to create custom-made shoes and futuristic designs, Syntilay is paving the way for the future of fashion.

AI-Driven Design Process

Syntilay leverages the potential of artificial intelligence to transform shoe design and production, allowing for greater creativity, accuracy, and efficiency.

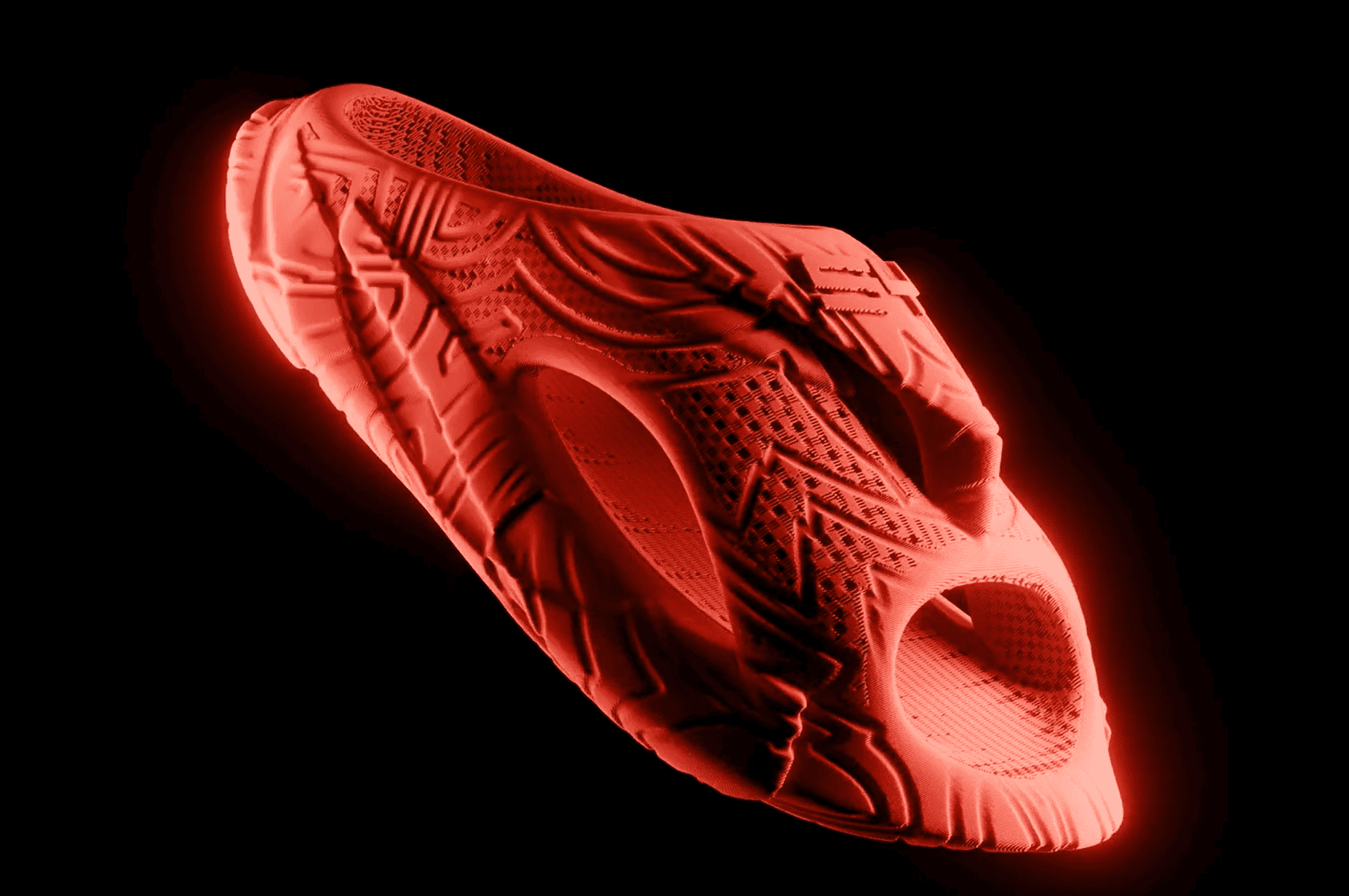

As part of their recent innovations, Syntilay utilized MidJourney to design footwear concepts that human designers could polish and supplement to meet their intended purpose. Later, once the shoes were built, they employed Vizcom AI to aid them in developing 3D models of the shoes. Generative AI is additionally used in constructing patterns, which, after view adjustment, display a perfect look. After creating multiple prototypes, a final 3D model is developed using robust materials such as thermoplastic polyurethane (TPU). While developing 3D models, patterns and textures are used, and many alteration phases are performed to ensure a flawless design and authenticity.

Syntilay can meet customers' growing needs, allowing them to ensure a perfect fit for the shoe by simply letting the customer take a foot scan using their device.

Image Source: Syntilay

3D Printing

Syntilay joins forces with Zellerfeld, a Germany-based factory specializing in 3D printing shoes, in an attempt to actualize the concept of AI-designed footwear. In contrast to the other brands, Zellerfeld features fused deposition modeling FDM printers, which have proven to be highly versatile, durable, and able to produce high-quality goods.

Syntilay and Zellerfeld combine to deliver the design shoes they offer. The shoes are custom-made out of thermoplastic polyurethane (TPU) material using an FDM 3D printer. TPU is flexible, comfortable, and durable. Syntilay x Zellerfeld delivers intricately designed shoes that seamlessly blend innovation with a functional purpose.

AI Design x 3D Printing

Combining AI and 3D printing has opened up new frontiers and possibilities across different fields. Perhaps the most important trend these days is making design accessible to everyone, as AI tools now facilitate the creation of products by individuals and even small corporations without the technical skills. AI x 3D printing urges different and nonstandard things to be made.

Material enhancements are equally important as they make it possible to construct extremely robust and functional products, which would include, yet not be limited to, custom shoes and intricate surgical tools. AI x 3D printing also encourages environmentally responsible operations because it reduces the amount of unused material. More sophisticated AI computer models help to correct variations in graphics in advance, during the printing process, and afterward.

AI x 3D Printing is used in the fashion, health, car, and aviation sectors to improve efficiency, reduce costs, and enhance the productivity of the supply industry.

In addition, new consumer-oriented remedies have appeared as AI x 3D printing responds to society's evolving patterns by enabling the market to create tailored and highly individualized products that meet consumers' needs. AI and 3D printing are set to change the way people design, manufacture, and buy goods in the future, and this shift will enhance innovation and ensure sustainability in all industries.

COMMENTS

- Be the first to share your thoughts!