What is 17-4 stainless steel?

17-4 stainless steel, also known as Type 630, is a precipitation-hardening martensitic stainless steel. It offers high strength, excellent corrosion resistance and ease of fabrication.

The alloy consists of about 17% chromium and 4% nickel, along with copper, niobium and other trace elements. The unique combination of these elements enables 17-4 stainless steel to achieve excellent mechanical properties through heat treatment.

17-4 stainless steel is widely used in various industries such as aerospace, medical and petrochemical due to its ability to withstand harsh environments and maintain structural integrity under high stresses. The balance of strength, toughness, and corrosion resistance makes 17-4 stainless steel a popular choice for manufacturing components such as gears, valves, and fasteners.

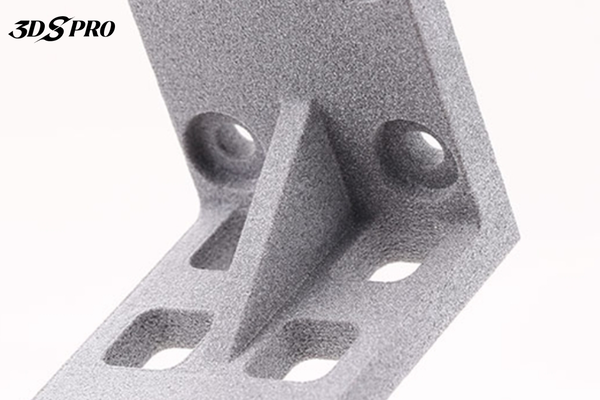

SLM 3D Printed 17-4 Stainless Steel:

17-4 Stainless Steel Properties

Here is a cheat sheet of SLM 3D printed 17-4 stainless steel properties:

|

Hardness |

38 HRC |

|

Relative Density |

96.4% |

|

Tensile Strength |

1230MPa |

|

Tensile Modulus |

170GPa |

|

Elongation at Break |

13% |

|

Yield Strength |

1050MPa |

|

Corrosion |

PASS |

SLM 3D Printing 17-4 Stainless Steel

SLM 3D printing with 17-4 stainless steel is widely used in industries that require high-strength, corrosion-resistant parts, such as aerospace, medical devices, and automotive.

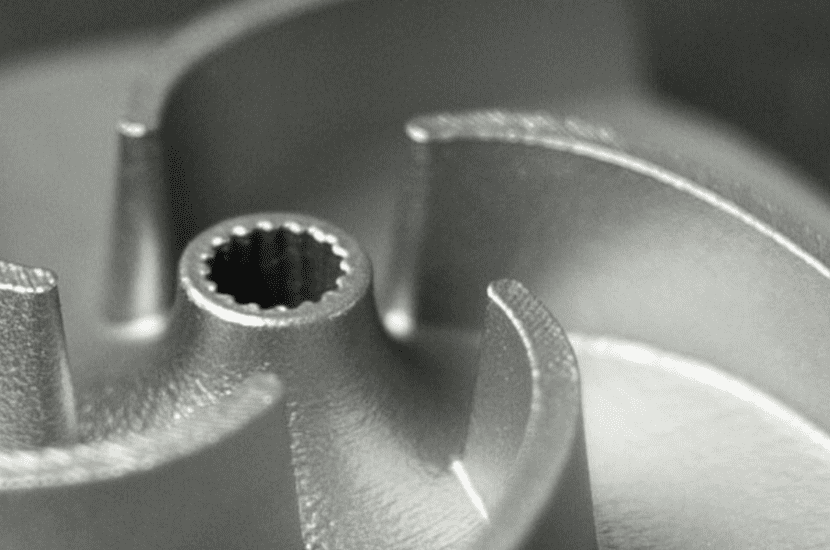

Aerospace

SLM 3D printed 17-4 stainless steel is used to manufacture lightweight, high-strength components such as turbine blades, brackets and fasteners that are critical to aircraft performance and safety.

Medical

In the medical field, this material is used in the production of surgical instruments, implants and prostheses due to its biocompatibility and corrosion resistance.

Automotive

The automotive industry benefits from SLM-printed 17-4 stainless steel for manufacturing durable parts such as gears, valves, and suspension components that can withstand harsh operating conditions.

Energy Sector

SLM-printed 17-4 stainless steel is used in the energy industry to produce parts that can withstand high temperatures and corrosive environments, such as heat exchangers and chemical processing equipment.

Designing Parts with 17-4 Stainless Steel

Optimize Geometries

Optimize geometries for 3D printing using Design for Additive Manufacturing (DfAM) principles, including reducing mass while maintaining strength, incorporating complex internal features that are difficult to achieve with traditional methods, and minimizing support structures.

Support Structures

Consider supports when designing. Identify overhangs, bridges, and angles that may require support structures during printing. Whenever possible, design your part to minimize the need for supports, as they increase post-processing time and material usage.

Wall Thickness

Maintain consistent wall thickness to ensure uniform material properties throughout the part. Avoid walls that are too thin, which can compromise structural integrity, or too thick, which can cause internal stresses and warping.

Tolerance and Fits

Consider the tolerances that are achievable using SLM 3D printing technology. Make sure parts designed to fit together have adequate clearance to accommodate any dimensional variations. Fine-tuning the design based on test prints can help achieve the desired fit and function.

Heat Treatment Considerations

Heat treating should be considered when designing parts, as 17-4 stainless steel can be hardened by a variety of heat treatments. The heat treatment process will affect dimensions and mechanical properties, so plan for any necessary allowances or adjustments in your design.

Stress Relief Features

Include features that reduce residual stresses, such as fillets at sharp corners and gradual transitions between sections. It helps prevent warping and cracking during printing and post-processing.

Post-Processing

Plan post-processing steps such as machining, polishing, and heat treatment. Make sure your design includes allowances for these processes to achieve the final desired dimensions and surface finish.

Recommended Post-processing Options

At 3DSPRO, we offer a range of post-processing options for 17-4 stainless steel parts. Our 3D Plus™ Solutions are designed to achieve the highest levels of durability and reliability for 3D printed parts.

For heat treatments, we have solution annealing and age hardening to enhance mechanical properties.

For surface treatment technology, we use polishing, bead blasting, sandblasting, and tumbling to get a smooth surface.

We also provide stress relief treatments to reduce residual stresses, protective coatings to enhance corrosion resistance, and comprehensive quality inspections to verify that your parts meet the required standards.

In addition, we also have spray painting, electroplating, electrocoating, powder coating, etc., to give your 3D printed 17-4 stainless steel a colorful surface.

COMMENTS

- Be the first to share your thoughts!