TPU 3D Printing: Flexibility & Durability

TPU is a flexible thermoplastic elastomer that combines the best of two worlds: the elasticity of rubber and the strength of plastic. The unique balance makes it ideal for applications where parts need to bend, stretch, or compress without breaking.

Key properties of TPU in 3D printing:

• Flexibility: TPU can bend and stretch repeatedly without losing shape.

• Durability: Resistant to abrasion, impact, and wear, TPU parts last longer under stress.

• Chemical Resistance: TPU withstands oils, greases, and many solvents, making it suitable for industrial environments.

• Temperature Tolerance: TPU maintains performance across a wide range of conditions.

From wearable devices to automotive seals, TPU enables designs that traditional plastics can’t achieve.

Image Copyright © 3DSPRO Limited. All rights reserved.

3DSPRO’s Advantages on TPU 3D Printing Service

While TPU is powerful, it’s also notoriously tricky to print. Its flexibility can cause issues like stringing, warping, or poor dimensional accuracy if not handled correctly. That’s where 3DSPRO’s expertise comes in.

Why choose 3DSPRO for TPU 3D printing?

• Specialized Equipment: Our SLS and MJF printers are optimized for TPU, ensuring consistent results.

• Material Expertise: We offer multiple TPU grades and shore hardness options to match your project’s needs (needs manual quotation, contact success@3dspro.com).

• Quality Assurance: Every part undergoes dimensional checks and surface inspections to guarantee accuracy.

• Scalable Production: From one-off prototypes to large production runs, we deliver with speed and reliability.

• Customer Support: Our team works with you to refine designs, troubleshoot challenges, and ensure your parts perform as intended.

Image Copyright © 3DSPRO Limited. All rights reserved.

TPU Applications We’ve Delivered

At 3DSPRO, we have helped clients across industries leverage TPU’s unique properties. Here are just a few examples:

• Wearable Technology: Flexible wristbands and protective casings that combine comfort with durability.

• Robotics: Soft grippers and vibration dampeners that allow machines to interact safely with delicate objects.

• Automotive: Custom gaskets, seals, and protective covers that withstand heat, oil, and constant stress.

• Consumer Goods: Custom jewelry and accessories, shock-absorbing phone cases, footwear components, and sports gear.

• Healthcare: Custom orthotics and prosthetic components designed for comfort and resilience.

Each of these applications demonstrates TPU’s ability to bridge the gap between prototype and production, offering performance and adaptability.

Image Copyright © 3DSPRO Limited. All rights reserved.

3D Printing Design Tips for TPU Parts

1. Wall Thickness & Strength

• SLS TPU: Minimum wall thickness of 1.5–2.0 mm is recommended for durability. Thin walls may be flexible, but risk tearing along the Z-axis.

• MJF TPU: Similar guidelines apply, but MJF often achieves more consistent strength across axes, allowing slightly thinner features.

2. Anisotropy Awareness

• SLS parts are anisotropic, so expect stronger properties in the XY plane than in Z. For load-bearing designs, orient parts to maximize strength in the direction of applied forces.

• MJF parts are closer to isotropic, but orientation still influences surface finish and fine details.

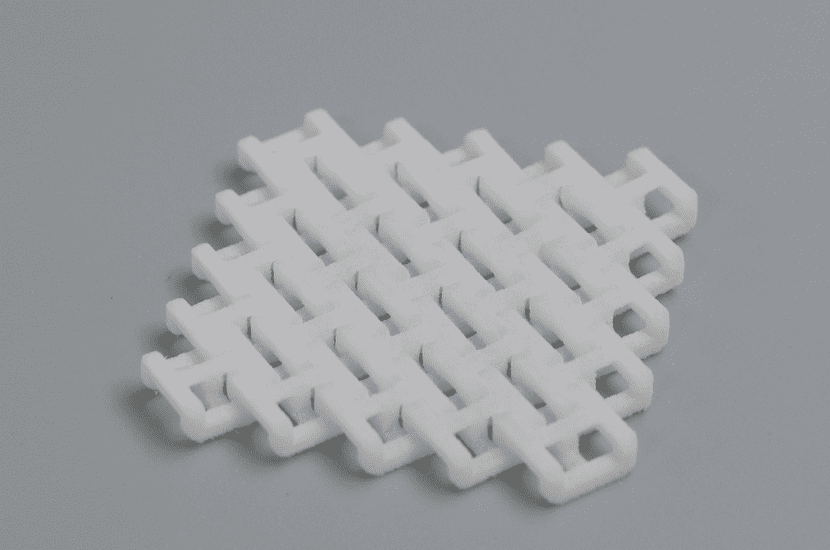

3. Clearances & Moving Parts

• Allow 0.6–0.8 mm clearance for interlocking parts. TPU’s elasticity means tight tolerances can cause binding.

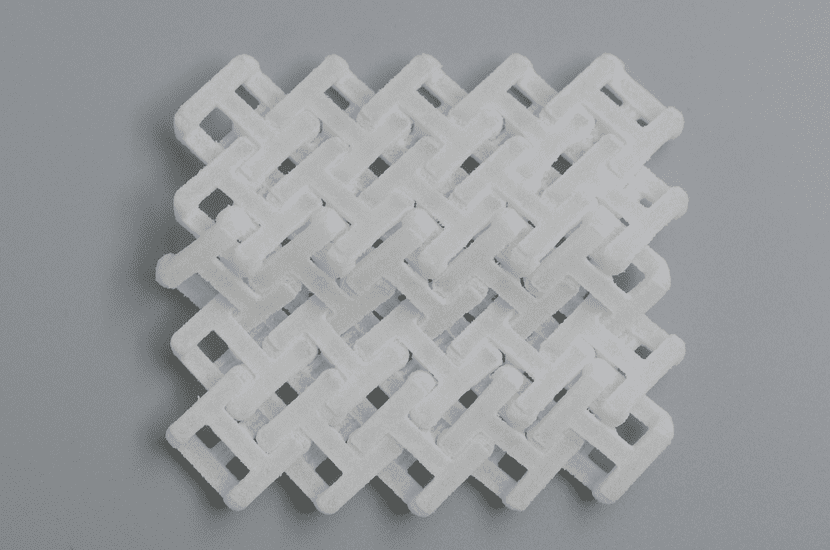

4. Lattice & Lightweight Structures

• Both SLS and MJF excel at lattice geometries. Use them to reduce weight while maintaining flexibility.

• Variable-density lattices can create zones of rigidity and flexibility within the same part.

5. Surface Finish & Post-Processing

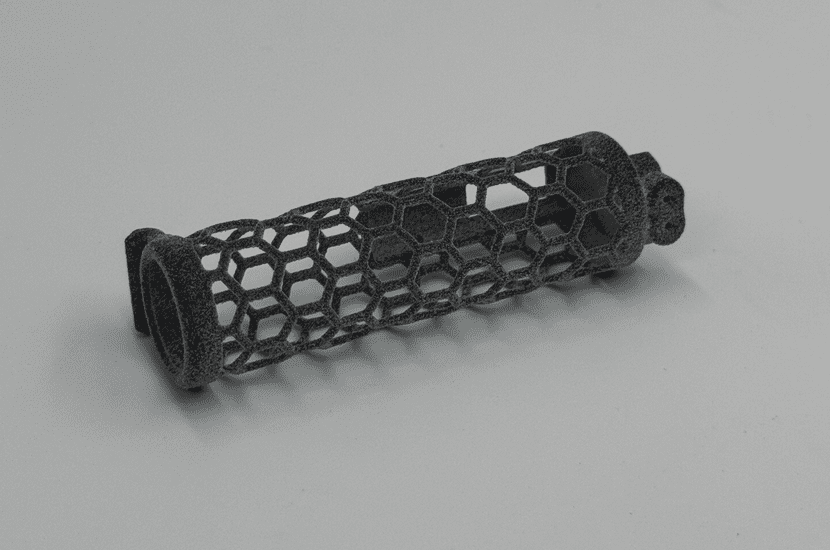

• SLS TPU: Slightly rougher, powdery finish; may require tumbling or coating for smoother surfaces.

• MJF TPU: Naturally darker and smoother, with better detail resolution. Can be dyed or finished for aesthetics.

6. Design for Flexibility

• Use variable wall thickness to engineer flexibility where needed.

• Curved geometries and ergonomic shapes take advantage of TPU’s elasticity.

7. Production Efficiency

• Nest parts efficiently in the build chamber to reduce cost per part.

• Both SLS and MJF are ideal for batch production of TPU parts, not just prototyping.

TPU vs Flexible Resin vs Nylon

|

Property |

TPU (Thermoplastic Polyurethane) |

Flexible Resin (Photopolymer) |

Nylon (Polyamide) |

|

Flexibility |

Excellent, elastic and bendable |

Good, but more brittle over time |

Moderate, semi-flexible |

|

Durability |

High abrasion and impact resistance |

Lower, prone to cracking |

High, especially in rigid applications |

|

Chemical Resistance |

Strong against oils and solvents |

Limited |

Good, but varies by grade |

|

Surface Finish |

Slightly textured, rubber-like |

Smooth, high detail |

Matte, slightly rough |

|

Best Use Cases |

Wearables, seals, dampeners, grippers |

Prototypes, visual models |

Functional parts, gears, housings |

How to Choose:

Choose TPU when you need true flexibility and durability.

Choose Flexible Resin for visual prototypes with smooth finishes.

Choose Nylon for rigid, load-bearing parts with some flexibility.

How to Get Started with TPU Printing at 3DSPRO

Ordering TPU parts with 3DSPRO is simple and streamlined:

1. Upload your design file (Support all common 3D printing file formats on the market, try it now>>).

2. Select TPU material options and surface finish.

3. Receive an instant quote with pricing and lead time.

4. Confirm your order and let our team handle the rest.

5. Receive your parts: prototypes or production-ready components delivered fast.

Our process is designed to save you time while ensuring you get the best possible results.

Image Copyright © 3DSPRO Limited. All rights reserved.

Ready to Print? Let’s Build Something Flexible Together

Whether you’re designing a new wearable, testing a robotic component, or producing industrial-grade seals, TPU 3D printing offers the flexibility, durability, and performance your project demands.

At 3DSPRO, we help you bring ideas to life. With our expertise, advanced equipment, and customer-first approach, you can trust us to deliver TPU parts that meet your exact needs.

Ready to get started? Upload your design today and discover how 3DSPRO’s TPU 3D printing services can make your next project stronger, more flexible, and production-ready.

COMMENTS

- Be the first to share your thoughts!