Aluminum has long been a key material of modern engineering, prized for its lightweight strength, corrosion resistance, and versatility. With the rise of additive manufacturing, aluminum alloys have become even more valuable, enabling engineers and designers to create complex geometries that were once impossible with traditional machining or casting.

But not all aluminum alloys are created equal. When it comes to 3D printing, two alloys dominate the conversation: A6061 and AlSi10Mg. Each offers unique benefits and trade-offs, making the choice between them critical for achieving the right balance of performance, cost, and manufacturability.

The Advantages of 3D Printing Aluminum

Aluminum is one of the most widely used metals in additive manufacturing, and for good reason. Its properties align perfectly with the demands of industries like aerospace, automotive, robotics, and consumer electronics.

Key advantages include:

1. Lightweight Strength: Aluminum alloys deliver high strength-to-weight ratios, making them ideal for structural parts where weight reduction is critical.

2. Thermal Conductivity: Excellent heat dissipation makes aluminum suitable for heat exchangers, housings, and electronic components.

3. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, extending the lifespan of parts in harsh environments.

4. Design Freedom: 3D printing allows engineers to create lattice structures, internal channels, and complex geometries that maximize aluminum’s potential.

5. Cost Efficiency: Compared to titanium or nickel alloys, aluminum is more affordable and widely available.

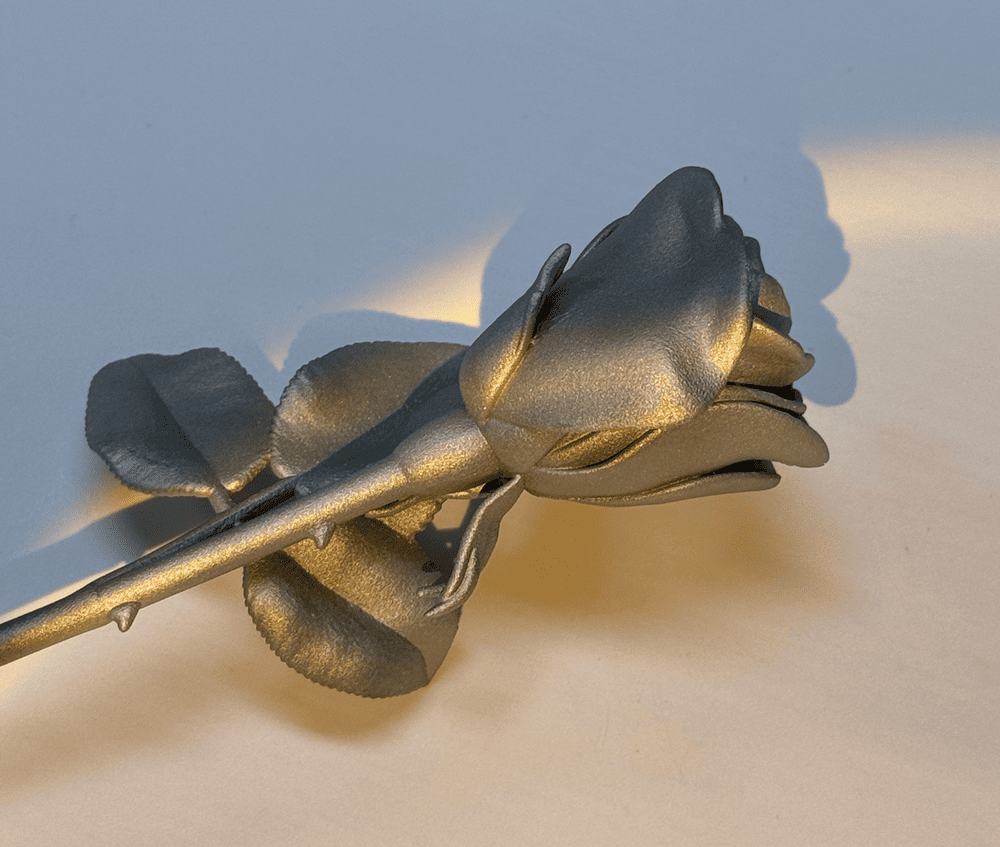

3D Printed Rose in Aluminum AlSi10Mg:

Image Copyright © 3DSPRO Limited. All rights reserved.

3D Printed Aluminum 6061: Strength & Versatility

A6061 is one of the most popular wrought aluminum alloys in traditional manufacturing, widely used in aerospace, automotive, and industrial applications. Its composition—primarily aluminum, magnesium, and silicon—gives it excellent mechanical properties and machinability.

Advantages of 3D Printed A6061:

1. High Strength and Toughness: Suitable for load-bearing and structural applications.

2. Excellent Machinability: Easy to post-process, drill, or mill after printing.

3. Familiarity in Industry: Engineers already trust A6061 in conventional manufacturing, making it a natural choice for additive.

Applications:

Aerospace brackets, automotive suspension components, tooling, and parts requiring both strength and machinability.

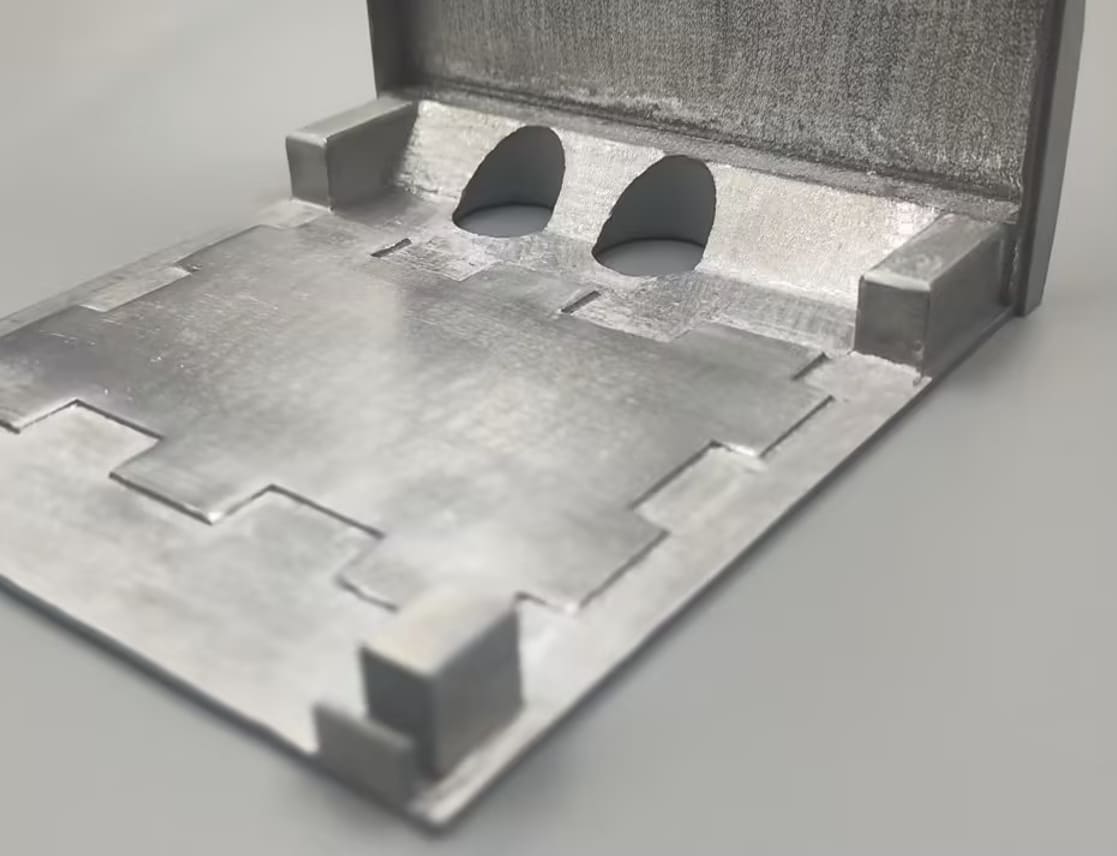

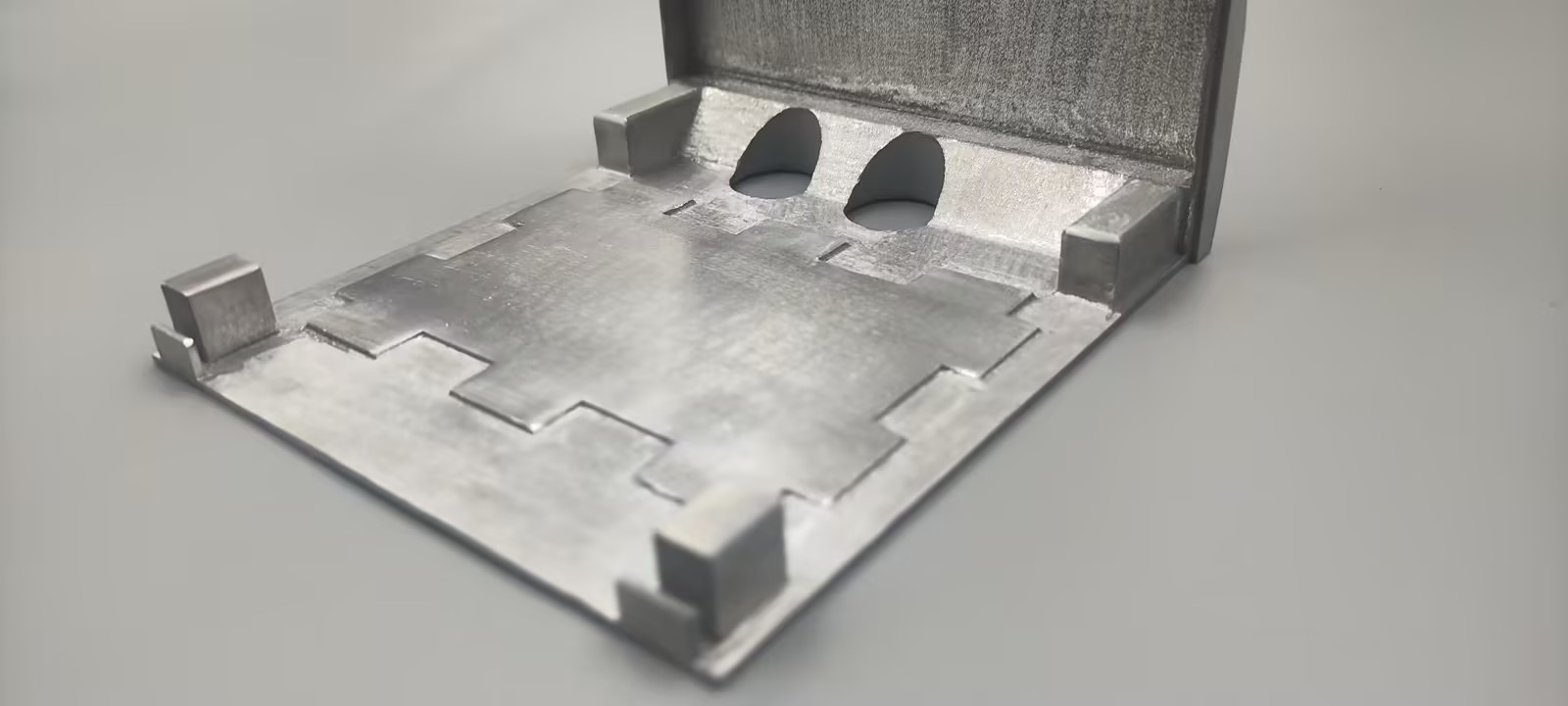

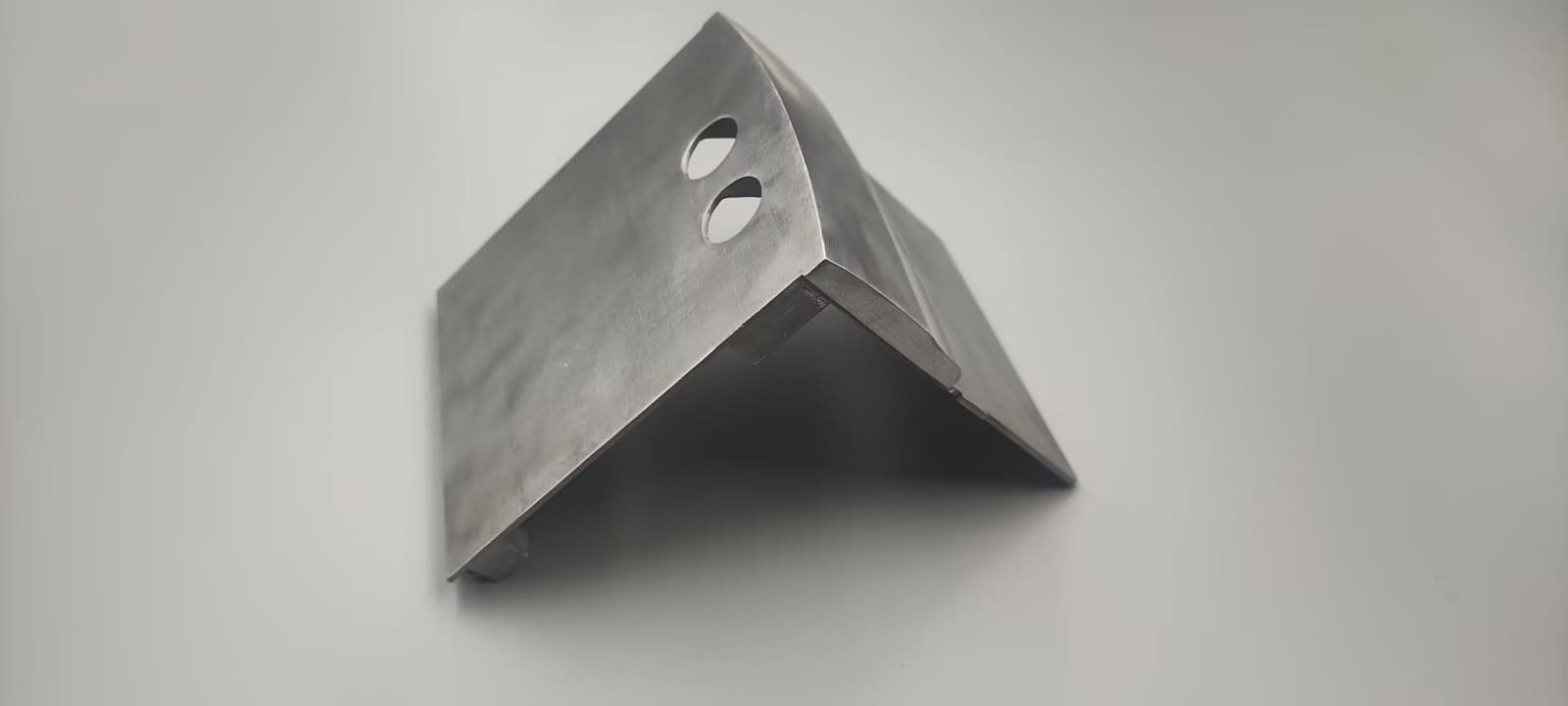

3D Printed Boost in Aluminum 6061:

Image Copyright © 3DSPRO Limited. All rights reserved.

3D Printed AlSi10Mg: Optimized Alloy

AlSi10Mg is an aluminum-silicon alloy specifically optimized for casting and additive manufacturing. Its composition includes about 10% silicon and small amounts of magnesium, which improve strength and corrosion resistance.

Advantages of 3D Printed AlSi10Mg:

1. Excellent Printability: Designed for additive manufacturing, it offers high dimensional accuracy and low risk of cracking.

2. Good Corrosion Resistance: Performs well in marine and outdoor environments.

3. Cost-Effective: More affordable than A6061 for most applications.

4. Fine Surface Finish: Produces smoother parts with less post-processing.

Applications:

Prototypes, housings, heat exchangers, consumer products, and lightweight structural parts where extreme strength is not the top priority.

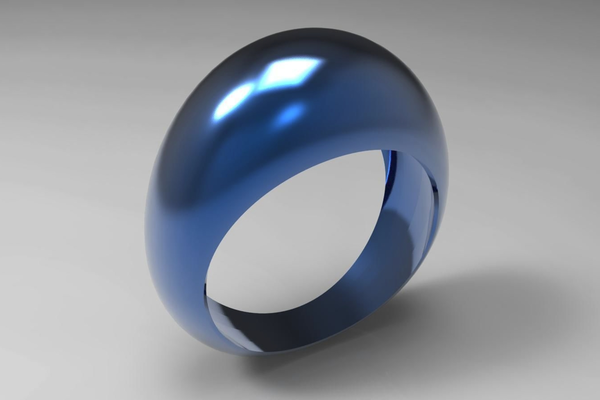

3D Printed & Polished AlSi10Mg Part:

Image Copyright © 3DSPRO Limited. All rights reserved.

A6061 vs. AlSi10Mg: Key Differences You Need to Know

|

Feature |

A6061 Aluminum |

AlSi10Mg Aluminum |

|

Strength |

Higher tensile strength |

Moderate but reliable |

|

Printability |

More difficult, prone to cracking |

Excellent, optimized for AM |

|

Corrosion Resistance |

Good |

Very good |

|

Machinability |

Excellent |

Moderate |

|

Cost |

Higher |

More affordable |

|

Surface Finish |

Requires more post-processing |

Naturally smoother |

|

Best Applications |

Aerospace, automotive, tooling |

Prototypes, housings, general parts |

Properties of 3D Printed A6061 at 3DSPRO:

|

Hardness |

ISO 6597-1:03-2006 |

95 HB |

|

Density |

WGE-Prod-067EN |

2.8 g/cm3 |

|

Relative Density |

WGE-Prod-067EN |

99.0% |

|

Tensile strength |

DIN EN ISO 6892-1:2009 |

290MPa |

|

Elongation at Break |

DIN EN ISO 6892-1:2009 |

10% |

|

Yield Strength |

DIN EN ISO 6892-1:2009 |

240MPa |

|

Elastic modulus |

DIN EN ISO 6892-1:2009 |

70GPa |

|

Roughness Ra |

ISO 4287 / AITM 1-00070 |

16 µm |

|

Roughness Rz |

ISO 4287 / AITM 1-00070 |

70 µm |

Image Copyright © 3DSPRO Limited. All rights reserved.

Properties of 3D Printed AlSi10Mg at 3DSPRO:

|

Hardness |

ISO 6597-1:03-2006 |

100 HV |

|

Density |

WGE-Prod-067EN |

2.65 g/cm3 |

|

Relative Density |

WGE-Prod-067EN |

99.0% |

|

Tensile strength |

DIN EN ISO 6892-1:2009 |

300MPa |

|

Elongation at Break |

DIN EN ISO 6892-1:2009 |

2.00% |

|

Yield Strength |

DIN EN ISO 6892-1:2009 |

190MPa |

|

Elastic modulus |

DIN EN ISO 6892-1:2009 |

70GPa |

|

Roughness Ra |

ISO 4287 / AITM 1-00070 |

16 µm |

|

Roughness Rz |

ISO 4287 / AITM 1-00070 |

70 µm |

Image Copyright © 3DSPRO Limited. All rights reserved.

Tips to Choose:

• Choose A6061: if you need maximum strength, machinability, and are willing to invest in advanced printing techniques.

• Choose AlSi10Mg: if you want reliable, cost-effective, and highly printable aluminum parts.

Choosing the Best Aluminum Alloy for Your 3D Printing Needs

The right alloy depends on your project’s priorities. Consider the following factors:

1. Mechanical Requirements: If your part must withstand high loads, A6061 is the better choice. For general-purpose parts, AlSi10Mg is sufficient.

2. Budget: AlSi10Mg is more cost-effective, especially for prototypes or small-batch production.

3. Post-processing: If you plan to machine or modify the part after printing, A6061 offers better machinability.

4. Industry Standards: Aerospace and defense industries often prefer A6061 due to its established track record.

5. Production Speed: AlSi10Mg prints more easily, reducing lead times.

Making the Right Choice at 3DSPRO

At 3DSPRO, we understand that material selection is one of the most critical decisions in any 3D printing project. That’s why our aluminum 3D printing service offers both A6061 and AlSi10Mg, supported by expert consultation to help you choose the right alloy.

Why choose 3DSPRO?

1. Technical Expertise: Our engineers are experienced in handling the challenges of printing A6061 and optimizing AlSi10Mg for precision results.

2. End-to-End Service: From design consultation to post-processing, we ensure your parts meet the highest standards.

3. Customer Focus: Whether you’re prototyping or scaling to production, we tailor our services to your needs.

4. Dedicated Surface Finishing Solutions: With more than 20 types of surface finishes for 3D prints, you will get custom and ready-to-use parts.

5. Price Match: With our price match service, you will get the best value for your investment by matching any lower price you find from other reputable providers.

By partnering with 3DSPRO, you gain more than just a printing service! You gain a trusted advisor who helps you unlock the full potential of aluminum additive manufacturing.

FAQs

Q: Which alloy is stronger, A6061 or AlSi10Mg?

A: A6061 generally offers higher tensile strength, making it better for load-bearing applications.

Q: Is AlSi10Mg cheaper than A6061?

A: Yes. AlSi10Mg is typically more affordable due to its easier printability and lower post-processing requirements.

Q: Can both alloys be used in aerospace applications?

A: Yes. However, A6061 is more common in aerospace due to its higher strength and established certification pathways.

Q: Do both alloys require heat treatment after printing?

A: Both can benefit from heat treatment, but A6061 often requires it to achieve optimal mechanical properties.

Q: Which alloy is better for prototypes?

A: AlSi10Mg is usually the better choice for prototypes thanks to its cost-effectiveness and ease of printing.

COMMENTS

- Be the first to share your thoughts!