Quick Comparison Cheat Sheet

|

Material |

Waterproof Level |

Best Printing Tech |

Post-Processing Needed? |

Ideal Use Cases |

|

★★★★☆ |

SLS / MJF |

No |

Food containers, chemical storage |

|

|

Nylon PA 12 |

★★★☆☆ |

SLS / FDM |

Yes (epoxy) |

Outdoor mechanical parts |

|

ABS |

★★★★☆ |

FDM |

Optional (vapor smooth) |

Plumbing prototypes |

|

Polycarbonate (PC) |

★★★★☆ |

FDM |

No |

Protective covers, bottles |

|

★★★★★ |

SLA / DLP |

Minimal |

Sealed housings |

|

|

PETG |

★★★★☆ |

FDM |

No |

Outdoor signage, beverage containers |

Best Waterproof & Water-Resistant 3D Printing Materials

Not all 3D printing materials are created equal when it comes to water resistance. Some are naturally hydrophobic, while others require sealing to prevent leaks.

1. Polypropylene (PP)

• Properties: Naturally hydrophobic, excellent chemical resistance, low density.

• Pros: Doesn’t absorb water, flexible yet durable, ideal for containers and fluid-handling parts.

• Cons: Warping can be an issue; requires specific print settings.

• Best for: Food containers, outdoor equipment, and chemical storage.

2. Nylon PA12

• Properties: Strong, abrasion-resistant, low moisture absorption compared to other nylons.

• Pros: Excellent mechanical strength, good for functional parts.

• Cons: Still slightly porous; benefits from sealing for long-term water exposure.

• Best for: Outdoor mechanical parts, sports equipment, and marine components.

3. ABS (Acrylonitrile Butadiene Styrene)

• Properties: Tough, impact-resistant, moderate water resistance.

• Pros: Can be vapor-smoothed to seal gaps; widely available.

• Cons: Without smoothing, micro-gaps can allow seepage.

• Best for: Plumbing prototypes, enclosures, automotive parts.

4. Polycarbonate (PC)

• Properties: Extremely strong, transparent, and low water absorption.

• Pros: High impact resistance, maintains clarity, suitable for pressure-bearing parts.

• Cons: Requires high printing temperatures; prone to warping without enclosure.

• Best for: Protective covers, water containers, safety equipment.

5. SLA/DLP Resins

• Properties: Photopolymer resins are inherently watertight when fully cured.

• Pros: Smooth surface finish, high detail, minimal porosity.

• Cons: Some resins can become brittle over time; choose engineering-grade for durability.

• Best for: Sealed housings, fluidic devices, decorative water-contact parts.

6. PETG (Polyethylene Terephthalate Glycol)

• Properties: Good chemical resistance, low moisture absorption, and easier to print than ABS.

• Pros: Strong layer adhesion, minimal warping, food-safe variants available.

• Cons: Slightly less impact-resistant than PC.

• Best for: Outdoor signage, beverage containers, weatherproof enclosures.

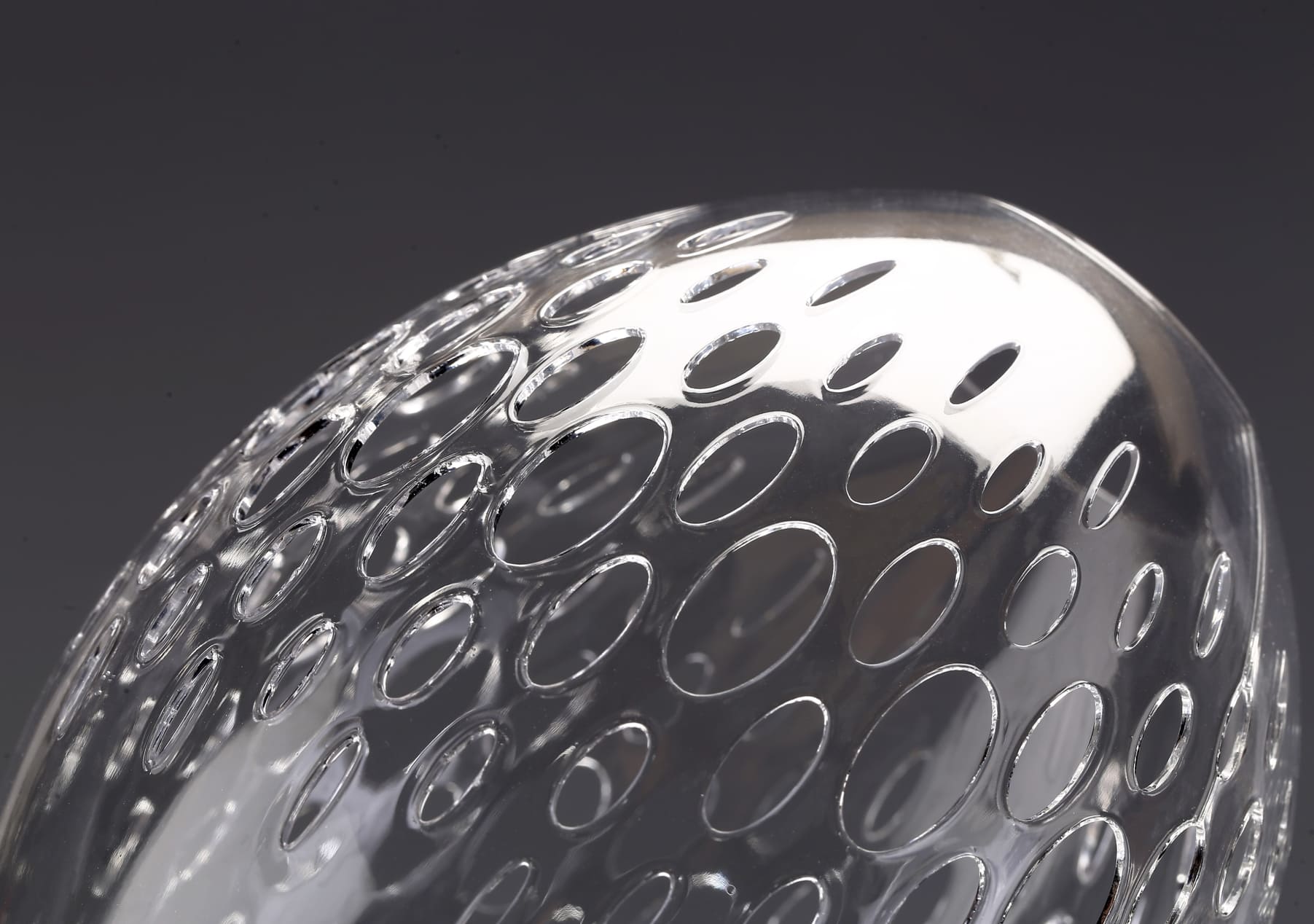

Image Copyright © 3DSPRO. All rights reserved.

Factors That Affect Water Resistance in 3D Prints

Even the most water-resistant material can fail if other factors aren’t optimized.

1. Material Porosity

Some plastics absorb water at the molecular level (e.g., standard nylon), while others repel it.

2. Printing Technology

SLA and DLP produce inherently watertight parts; FDM prints have microscopic gaps between layers.

3. Layer Adhesion

Poor bonding creates leak paths.

4. Wall Thickness

Thin walls are more prone to seepage.

5. Infill Density

Higher infill reduces internal voids where water can accumulate.

6. Surface Finish

Rough surfaces can trap water and accelerate degradation.

Design Tips for Maximum Water Resistance

1. Increase Wall Thickness: Aim for at least 2–3 mm for functional waterproof parts.

2. Use 100% Infill for Critical Areas: Eliminates internal cavities that can leak.

3. Optimize Layer Height: Smaller layer heights improve bonding and reduce gaps.

4. Avoid Complex Internal Channels: Hard-to-seal areas can trap water.

5. Print Orientation: Position parts to minimize seam lines in water-contact areas.

6. Add Overlaps in Perimeters: Slightly over-extruding perimeters can improve sealing.

Post-Processing to Achieve True Waterproofing

Epoxy Resin Coating

Epoxy resin coating is one of the most reliable ways to make a 3D printed part truly waterproof, because it creates a continuous, non-porous barrier over the surface of the print. It works by filling in microscopic gaps between layers and sealing any tiny pores that could let water seep through.

Vapor Smoothing

Vapor smoothing is a post-processing technique used to improve the surface finish and water resistance of certain 3D printed parts — especially those made from acetone-soluble thermoplastics like ABS and ASA.

Image Copyright © 3DSPRO. All rights reserved.

It works by exposing the print to solvent vapors that soften and partially melt the outermost layer, causing the material to flow slightly and fuse together. This seals microscopic gaps between layers, creating a smooth, glossy, and more watertight surface.

Heat Treatment

Heat treatment, often called annealing in 3D printing, is a post‑processing method where a printed part is exposed to controlled heat to improve its strength, dimensional stability, and, in some cases, water resistance.

It works by allowing the polymer chains inside the material to rearrange and bond more tightly, reducing internal stresses and closing microscopic gaps that can let water seep through.

Sealants & Paints

Sealants & paints are surface-applied coatings used to protect 3D printed parts from water ingress, UV damage, and environmental wear. They work by forming a continuous, impermeable layer over the print, blocking moisture from penetrating through the layer lines or porous areas.

UV Curing (Resin Prints)

UV curing is the essential final step for most resin 3D prints (SLA, DLP, LCD/MSLA) that ensures the part reaches its full strength, durability, and water resistance.

When a resin print comes off the build plate, it’s only partially cured; the photopolymerization process has solidified the shape, but the material still contains uncured resin molecules. UV curing completes this process, locking in the part’s mechanical and chemical properties.

Waterproof vs. Watertight

Waterproof = what the material is.

Watertight = what the finished object does.

A watertight print can be made from a non-waterproof material if the design and sealing are done correctly.

|

Feature |

Waterproof |

Watertight |

|

Definition |

Material blocks water at molecular level |

Object prevents water ingress via design |

|

Depends On |

Material composition |

Geometry, print quality, sealing |

|

Example Material |

Polypropylene, SLA resin |

PLA with epoxy coating |

|

Durability |

Long-term without extra sealing |

May degrade if seal is damaged |

|

3D Printing Impact |

Less post-processing needed |

Requires sealing or special print settings |

COMMENTS

- Be the first to share your thoughts!