Core Advantages of MJF for Design

1. No Support Structures Required

The surrounding powder fully supports overhangs and complex geometries, eliminating support scars, reducing post-processing, and unlocking enclosed channels, internal lattices, and nested assemblies. Plan powder escape paths for closed volumes to keep parts lightweight and clean.

2. High Dimensional Accuracy

• Typical tolerances: ±0.3% (minimum ±0.3 mm)

• Consistent accuracy across the build volume, making it suitable for functional prototypes and end-use parts.

3. Fine Feature Resolution

• Layer thickness of 80 μm allows for crisp details, small text, and intricate geometries.

• Excellent for parts with small holes, embossed/engraved features, and complex surface textures.

4. Isotropic Mechanical Properties

• Uniform strength in all directions due to the powder bed fusion process.

• Ideal for load-bearing applications and mechanical assemblies.

5. Fast Production Speeds

• Entire layers are fused simultaneously, enabling faster turnaround than point-by-point laser systems.

• Well-suited for low-to-mid volume production.

6. Material Versatility

• Common options: PA12, PA11, PA12 Glass Bead (GB), TPU.

• Each material offers distinct mechanical and thermal properties, enabling a wide range of applications.

Copyright © 3DSPRO. All rights reserved.

General Design Considerations for MJF

1. Wall Thickness

• Supported walls: ≥ 0.5 mm

• Unsupported walls: ≥ 1.0 mm

• Thicker walls improve strength but increase weight and cost.

2. Holes & Channels

• Minimum hole diameter: 1.0 mm for through-holes.

• For enclosed channels, add escape holes (≥ 2 mm) for powder removal.

3. Text & Details

• Embossed/engraved text: ≥ 0.5 mm depth/height for legibility.

• Use sans-serif fonts for better readability.

4. Part Orientation

• Orient parts to minimize visible layer lines on critical surfaces.

• Consider load direction for mechanical performance.

5. Shrinkage & Warping

• MJF parts typically shrink ~0.4% during cooling.

• Avoid large flat surfaces without reinforcement to reduce warping.

Copyright © 3DSPRO. All rights reserved.

Assembly & Multi-Part Printing

1. Printing Assemblies in One Build

• Possible to print moving parts fully assembled.

• Maintain 0.5 mm clearance between moving surfaces to prevent fusion.

2. Tolerances for Fits

• Press-fit: 0.1–0.2 mm interference.

• Slip-fit: 0.2–0.5 mm clearance.

• Test with prototypes before committing to production.

3. Modular Design

• Split large parts into smaller modules for easier printing and post-processing.

• Use interlocking features or mechanical fasteners for assembly.

4. Powder Removal in Assemblies

• Ensure adequate escape holes for enclosed spaces.

• Design internal channels with smooth curves to aid powder flow.

Lightweighting & Internal Structures

1. Hollowing Strategies

• Hollow thick sections to save material and reduce cost.

• Maintain ≥ 2 mm wall thickness for structural integrity.

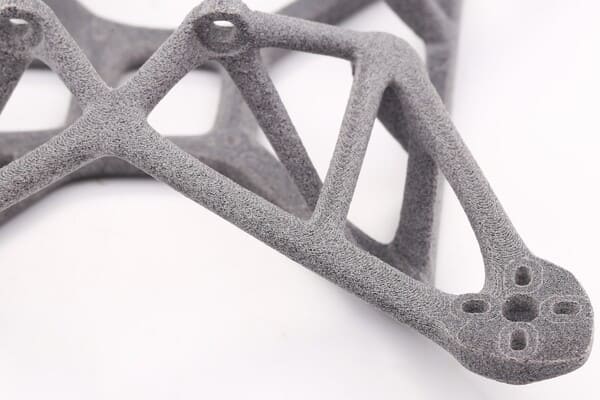

2. Lattice Structures

• Use lattice infills to maintain stiffness while reducing mass.

• Consider gyroid or diamond lattices for balanced strength and powder removal.

3. Topology Optimization

• Use simulation tools to remove non-critical material.

• Combine with MJF’s ability to print complex geometries for maximum efficiency.

4. Powder Removal Considerations

• For hollow or lattice-filled parts, include multiple escape holes (≥ 2 mm).

• Position holes in non-critical areas for aesthetics.

Common Design Mistakes to Avoid

1. Ignoring Minimum Feature Sizes

• Features below the recommended limits may fuse, break, or fail to print.

2. Overlooking Powder Escape

• Enclosed powder can add weight, affect balance, and trap heat during post-processing.

3. Unsupported Thin Walls

• Thin, tall walls without bracing can warp or break during depowdering.

4. Overly Tight Tolerances

• Designing with injection molding tolerances can lead to assembly issues.

• Always account for MJF’s ±0.3% dimensional variation.

5. Neglecting Post-Processing Allowances

• Dyeing, vapor smoothing, or coating can add thickness; plan for it in CAD.

Cost Optimization Strategies

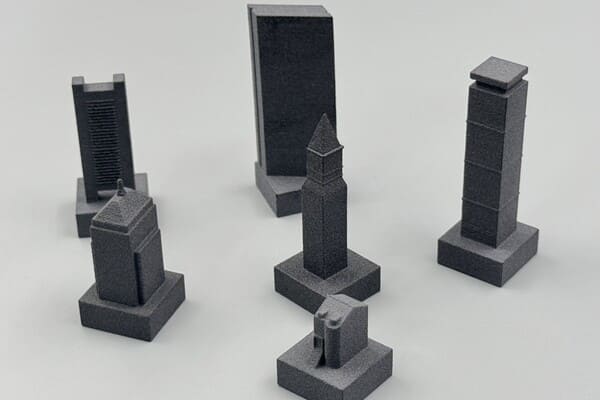

1. Nesting & Build Volume Utilization

• Arrange parts efficiently in the build chamber to maximize throughput.

• Stack parts vertically when possible, leaving enough clearance for powder removal.

2. Material Selection

• Choose the right material for the application: PA12 for general use, PA12 GB for stiffness, PA11 for impact resistance, and TPU for flexibility.

• Avoid over-specifying materials that increase cost unnecessarily.

3. Reduce Part Volume

• Hollowing and lattice structures not only reduce weight but also lower material usage.

• Minimize solid mass in non-critical areas.

4. Combine Parts

• Consolidate multiple components into a single printed part to reduce assembly labor and fasteners.

5. Optimize Wall Thickness

• Thicker walls increase cost; use the minimum thickness that meets performance requirements.

6. Batch Production

• Printing multiple parts in one build reduces per-part cost.

• Group similar parts to streamline post-processing.

Copyright © 3DSPRO. All rights reserved.

COMMENTS

- Be the first to share your thoughts!