Common Causes of Poor Bed Adhesion

Bed adhesion issues can derail even the most carefully planned 3D print. Here’s what’s likely going wrong:

Uneven or Unlevel Bed

A tilted or warped bed creates gaps between the nozzle and build plate, preventing proper “squish” on the first layer.

Incorrect Bed Temperature

Too cold, and materials like PLA or ABS won’t stick; too hot, and they might curl or warp.

Dirty Build Surface

Oils from fingerprints, dust, or leftover residue reduce grip.

Wrong Nozzle Height

A nozzle too high won’t press filament into the bed; too low can cause scraping or clogs.

Poor Surface Compatibility

Some materials (e.g., PETG) require specific surfaces (textured PEI, glue stick) to adhere properly.

Environmental Factors

Drafts, humidity, or temperature fluctuations destabilize the printing environment.

Step-by-Step Solutions

1. Level the Bed Properly

Manual Leveling: Use the “paper test” (slide a sheet under the nozzle; slight resistance = correct gap).

Auto-Leveling: Run your printer’s mesh bed leveling and adjust the Z-offset if needed.

2. Optimize Bed Temperature

PLA: 50–60°C

ABS: 90–110°C

PETG: 70–80°C

Preheat the bed for 5–10 minutes before printing.

3. Clean and Prepare the Build Surface

Wipe with 90% isopropyl alcohol to remove oils.

For stubborn residue, wash with warm water and dish soap.

Apply adhesives like glue sticks or hairspray for tricky materials (e.g., PETG on glass).

4. Adjust Nozzle Height

Use your printer’s “Live Z-Offset” setting to fine-tune the first layer. The filament should flatten slightly without being translucent.

5. Block Drafts and Stabilize Humidity

Close windows or use an enclosure to prevent cooling drafts.

Store filament in a dry box to avoid moisture-related warping.

Advanced Troubleshooting

If basic fixes don’t work, try these pro-level strategies:

1. Calibrate Z-Offset with a feeler gauge: replace the paper test with a 0.1mm feeler gauge for precision.

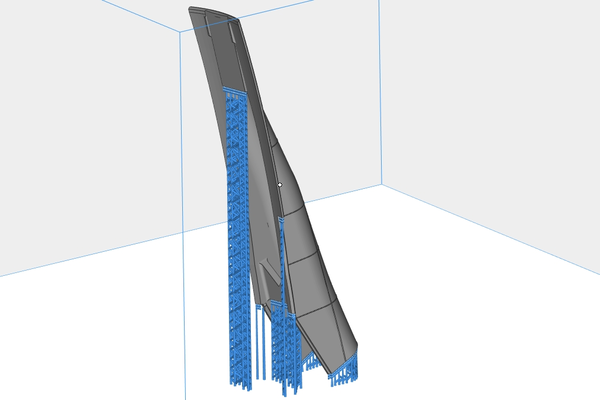

2. Slow down the first layer: reduce the first layer speed to 10–15mm/s (in slicer settings) for better bonding.

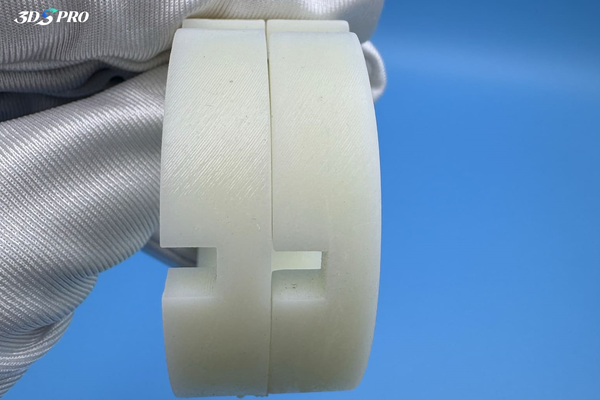

3. Use brims or rafts: add a brim (extends the first layer’s edges) or raft (a disposable base) for warp-prone materials like ABS.

4. Check for a warped bed: use a straightedge ruler to identify dips/bumps. Shim the bed with aluminum foil or upgrade to a glass plate.

5. Dry wet filament: bake moisture-soaked filament in a 45–50°C oven for 4–6 hours (make sure to read manufacturer guidelines carefully).

Tips Cheat Sheet

|

Category |

Action |

|

Bed Prep |

Clean with IPA, apply glue stick for PETG/TPU, heat bed to material spec. |

|

Leveling |

Re-level monthly; use mesh leveling if available. |

|

First Layer |

Slow speed (15mm/s), 105% extrusion width, 0.2mm height. |

|

Environmental |

Use enclosures for ABS, avoid printing in drafty areas. |

|

Filament Care |

Store in sealed bags with desiccant; dry before use. |