What is PETG filament?

PETG filament is a 3D printing material known for its clarity, strength, and flexibility. It stands for Polyethylene Terephthalate Glycol-modified, which is a variation of the standard PET material (commonly used in water bottles). This modification process involves the addition of glycol, which alters the material's molecular structure, resulting in different mechanical properties such as increased flexibility and reduced brittleness.

Image Source: newegg

Mechanical Properties of PETG Filament

● Strength and Durability: PETG has a higher tensile strength than PLA, which means it can withstand more pulling force before breaking. It’s less brittle and more durable, which is why it’s often used for functional parts that require toughness.

● Flexibility: While not as flexible as TPU or other rubber-like materials, PETG does offer a degree of flexibility, which makes it resistant to impact and less likely to shatter upon being dropped.

● Temperature Resistance: PETG has a higher thermal resistance than PLA. It can withstand temperatures up to about 70°C —80°C without deforming, making it suitable for objects that might experience higher temperatures during use.

● Layer Adhesion: One reason PETG is easy to print with is its excellent layer adhesion. This property reduces the likelihood of warping and makes the prints more stable and structurally sound.

● Chemical Resistance: PETG is resistant to many chemicals, including acids and alkalis, which makes it a good choice for containers and parts that may be exposed to harsh substances.

● Low Shrinkage: PETG experiences very low levels of shrinkage when cooling, which contributes to its excellent dimensional stability and makes it easier to print large objects.

● Hardness: PETG is harder than PLA, which means it’s more scratch-resistant and can handle more wear and tear.

PETG Filament Variants

● Standard PETG: This is the most common form of PETG used in 3D printing. It offers a good balance between strength, durability, and ease of printing.

● Translucent and Clear PETG: These variants are designed to maximize the natural translucency of PETG. They are ideal for creating objects that require a glass-like appearance.

● Color PETG: PETG is available in a wide range of colors, including solid, transparent, and fluorescent options, which allows for more creative and aesthetically pleasing prints.

● Composite PETG: Some PETG filaments are mixed with other materials like carbon fiber or glass fiber to enhance certain properties. For example, carbon fiber-reinforced PETG offers increased stiffness and strength, making it suitable for structural components.

● FDA-Approved PETG: This variant of PETG is certified for food contact applications. It’s made with food-safe dyes and additives, ensuring that the filament can be used for kitchenware, containers, and other items that come into contact with food.

● UV-Resistant PETG: Some PETG filaments are treated to be more resistant to UV light, preventing the material from degrading in sunlight, which makes it suitable for outdoor applications.

● Recycled PETG: Some manufacturers offer PETG made from recycled materials in an effort to be more environmentally friendly. This filament has a lower environmental impact while still providing the benefits of standard PETG.

Printer Setting for PETG Filament

Here’s a guide to help you configure your printer for PETG:

Extruder Temperature: PETG prints best at an extruder temperature range of 230°C to 250°C. Start at the lower end and increase if needed for better layer adhesion.

Bed Temperature: A heated bed is crucial for PETG. Set the bed temperature between 70°C and 90°C to ensure the first layers stick well without warping.

Print Speed: PETG should be printed at a moderate speed, typically between 40mm/s to 60mm/s. Slower speeds may be necessary for intricate details or sharp corners.

Cooling Fan: Use the cooling fan sparingly with PETG. Start with it off for the first few layers to promote adhesion, then set it to 50% - 60% after the foundation is established.

Retraction Settings: PETG is prone to stringing, so retraction settings are important. A retraction distance of 1mm to 3mm and a retraction speed of 40mm/s to 60mm/s are good starting points.

Layer Height: A layer height of 0.1mm to 0.3mm works well with PETG, providing a balance between surface finish and print time.

Nozzle Distance: The first layer is key to a successful print. Ensure the nozzle is close enough to the bed to squish the filament slightly but not so close that it drags or blocks extrusion.

Nozzle Diameter: Standard 0.4mm nozzles work well with PETG, but larger diameters can be used for faster prints or smaller diameters for finer details.

Image Source: RECREUS

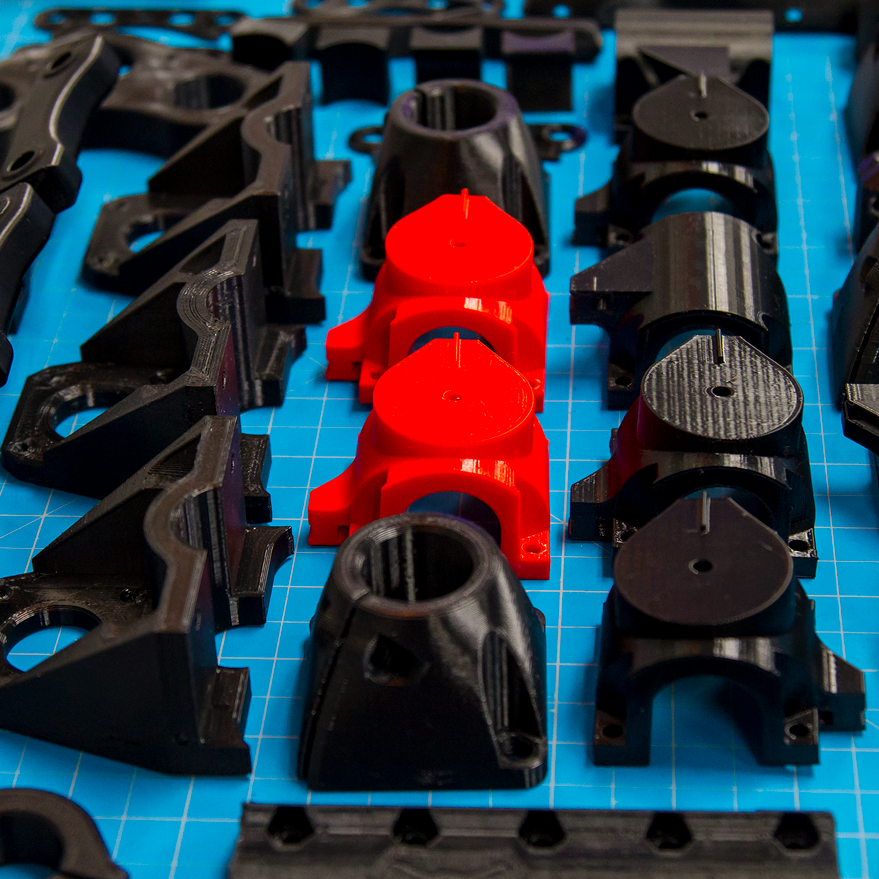

PETG Filament Applications

1. Medical Devices: PETG's strength and FDA-approved variants make it ideal for creating medical devices and prosthetics that are durable, sterilizable, and safe for human contact.

2. Protective Components: Its impact resistance makes it perfect for manufacturing protective gear such as face shields, safety goggles, and helmet components.

3. Automotive Parts: The filament's temperature and chemical resistance allow for the production of parts that can withstand the demanding conditions of automotive use.

4. Food Containers: Food-safe PETG can be used to print items like water bottles, food storage containers, and other kitchenware.

5. Functional Prototypes: Engineers and designers often use PETG to create functional prototypes that can endure rigorous testing.

6. Outdoor Applications: UV-resistant PETG is used for outdoor fixtures and signage that require durability against the elements.

Image Source: MatterHackers

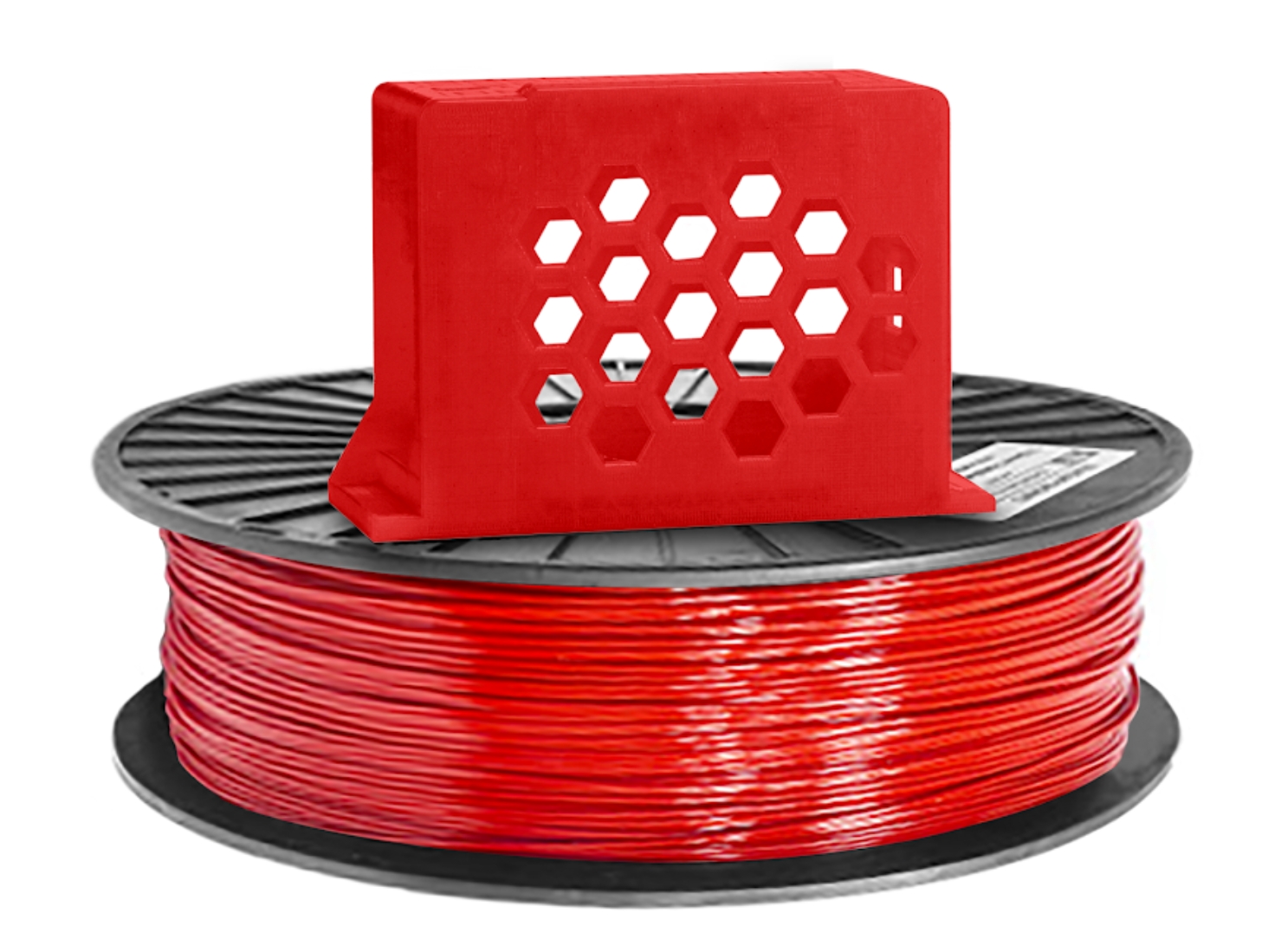

Best PETG Filaments

1. MH Build Series PETG Filament

MH Build Series PETG Filament is a top-selling product from MatterHackers designed for 3D printing enthusiasts looking for an affordable yet strong filament option. This 1.75mm PETG filament is perfect for creating durable and quality parts, and it’s priced competitively to fit every user’s budget. With bulk pricing available, the more you buy, the more you save per spool. It’s compatible with a wide range of 3D printers.

Image Source: MatterHackers

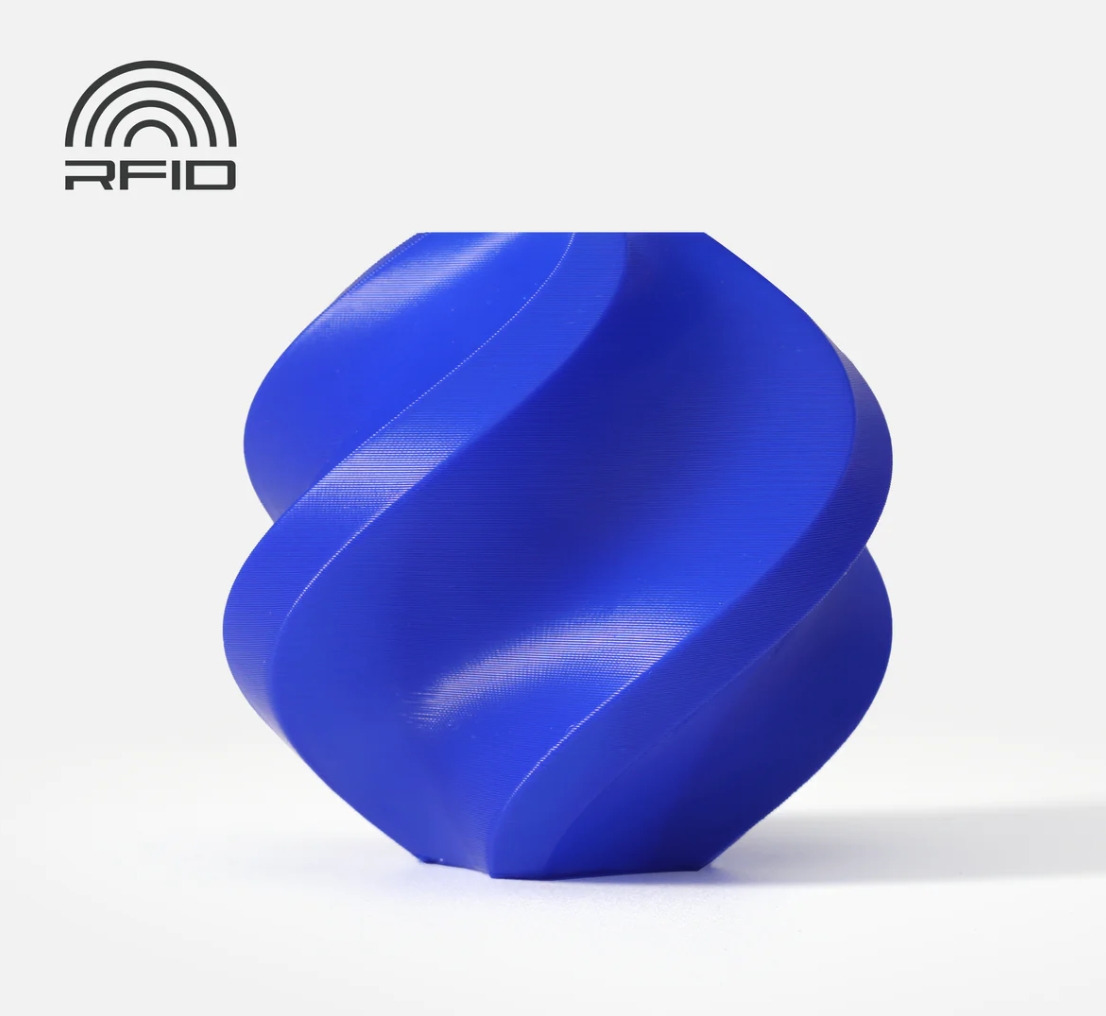

2. MH PRO Series PETG Filament

MH PRO Series PETG Filament is a premium 3D printing material that stands out for its exceptional toughness and minimal shrinkage. This 1.75mm filament is ideal for projects requiring parts that are both impact-resistant and flexible. Engineered to enhance PETG’s natural properties, such as durability, heat, and chemical resistance, the MH PRO Series PETG ensures your prints are not only high-quality but also consistent in performance.

Image Source: MatterHackers

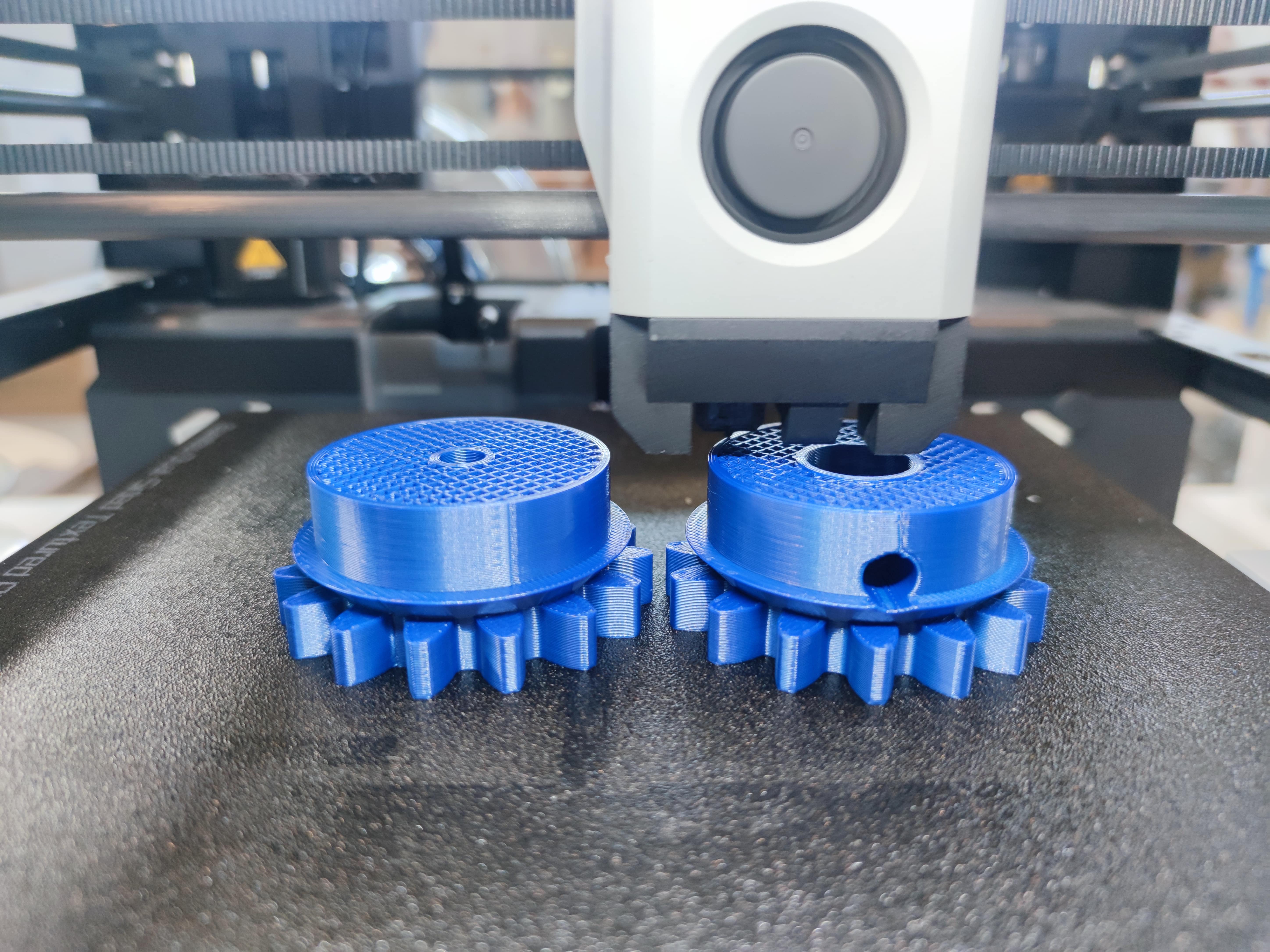

3. Bambu Lab PETG Basic

Bambu Lab’s PETG Basic Filament is a versatile and durable material designed for a wide range of applications. This filament is known for its impact and water resistance, high flexibility, and strong layer adhesion. It is an ideal choice for printing tools, toys, water containers, and outdoor items that require long-term durability and resilience.

Image Source: Bambu Lab

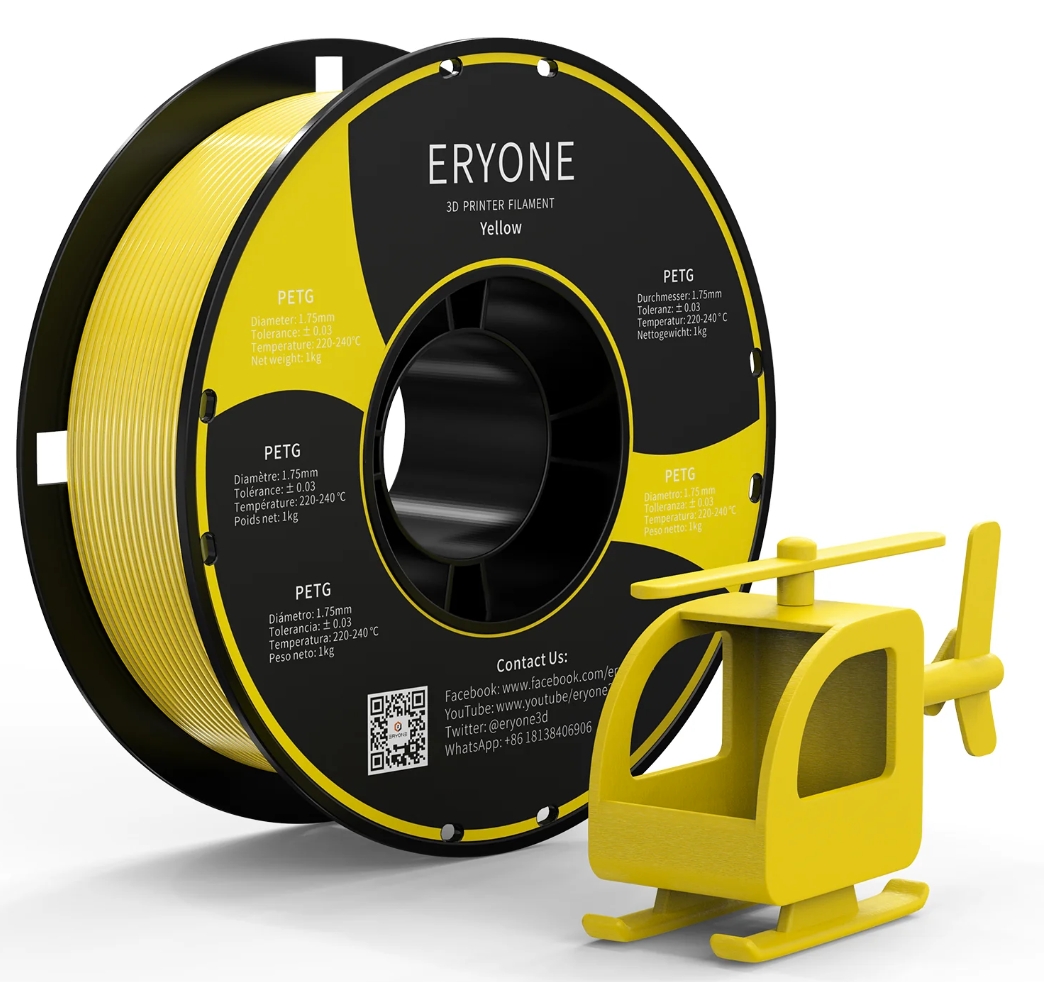

4. ERYONE PETG Filament

Eryone PETG Filament is a versatile 3D printing material that combines the ease of PLA printing with the strength and flexibility of ABS. With a higher toughness than PLA and an impact strength of more than 30 times that of standard PLA, Eryone PETG is perfect for creating durable, high-quality prints.

Image Source: ERYONE

5. FlashForge PETG Filament

FlashForge’s PETG Filament is a versatile and reliable material that promises high-quality prints every time. This 1.75mm PETG filament is designed to work seamlessly with a variety of FlashForge models, ensuring smooth feeding and extrusion. With a printing temperature range of 230-250°C and a speed of 60-90mm/s, it’s optimized for both speed and precision.

Image Source: FlashForge

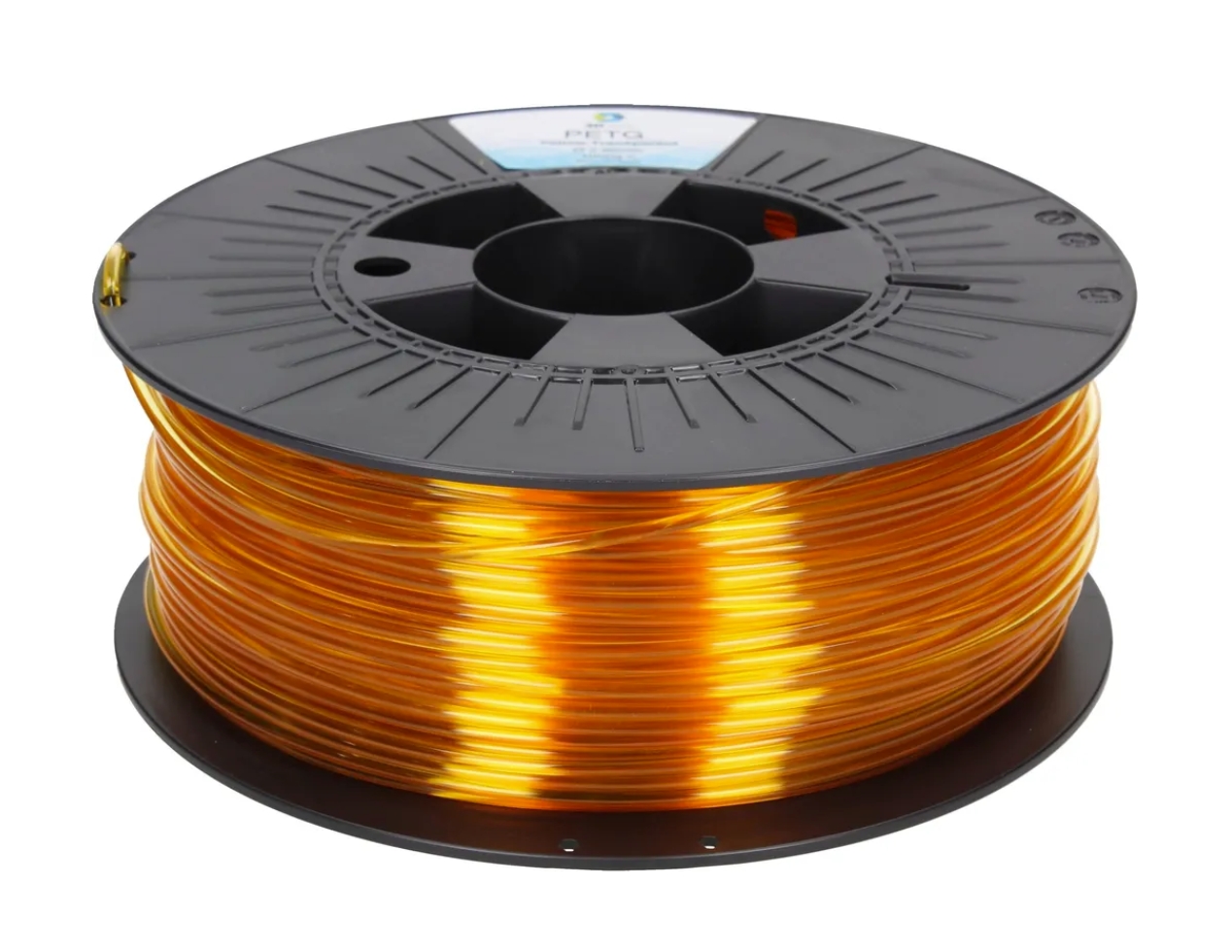

6. 3DJAKE PETG Filament

3DJAKE’s PETG Yellow Transparent Filament is specially modified to offer excellent mechanical and visual properties. The transparent yellow color adds a unique, eye-catching quality to your prints, while the filament’s water-repellent nature and strong layer adhesion ensure durable and reliable results. With recommended processing temperatures of 230 - 250°C, it’s easy to print and perfect for those seeking to combine aesthetic appeal with functional strength.

Image Source: 3DJAKE

7. HATCHBOX Silver PETG Filament

HATCHBOX Silver PETG Filament boasts easy adhesion to a variety of surfaces. The recommended print temperature range is 230°C - 260°C. The filament’s environmental safety and odorless nature make it a conscientious choice for all your printing needs.

Image Source: HATCHBOX 3D

8. Prusament PETG Filament

Prusament PETG Neon Green Transparent Filament, a high-quality filament from Prusa Research, is known for its low thermal expansion and toughness. It is ideal for printing large objects that require precision and durability. The neon green transparency adds a striking visual effect to your prints, while the filament’s flexibility ensures parts can withstand pressure without breaking. It’s a great choice for both functional and aesthetic applications.

Image Source: Prusament

COMMENTS

- Be the first to share your thoughts!

Check out Our Special Offers

Featuring Process

- Coming Soon

Featuring Materials

- Coming Soon