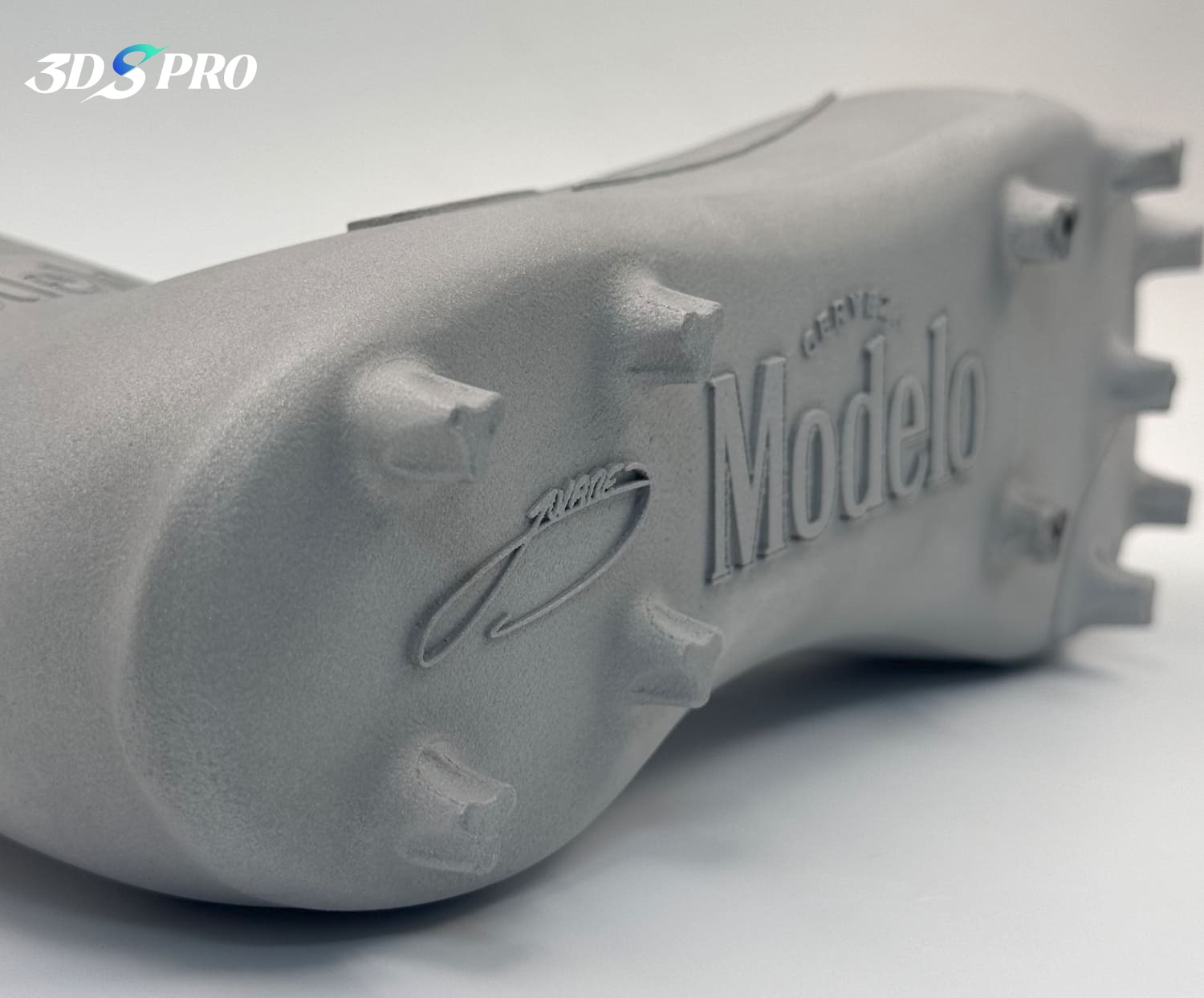

Aluminum 6061 is Used to Create a Life-size Boot

We teamed up with Bennett Awards to bring an exciting new product to life: life-size 3D printed metal boots! This is something the market hasn’t seen before. Bennett Awards is a family-owned business with over 50 years of experience in awards and fine art. For this project, they needed the speed and precision that only metal 3D printing could offer. They came to us with a vision to create twenty life-size boots using Aluminum 6061, and we were thrilled to take on the challenge!

Our Selective Laser Melting Capabilities

We offer high-precision SLM 3D printing services, capable of creating complex geometries using high-powered lasers to selectively melt and fuse metal powders. Our SLM printing supports a wide range of metals, including aluminum, stainless steel, titanium, and superalloys, making it suitable for aerospace, medical, automotive, and industrial applications. Besides, SLM provides a fast turnaround, ideal for projects with tight deadlines, and can process parts up to 420mm x 420mm x 450mm. The resulting 3D printed metal parts have excellent mechanical properties, including high strength, good thermal performance and outstanding dimensional accuracy, ensuring they have outstanding performance and quality.

|

Process |

Price |

Lead Time |

Maximum Printing Size |

Available Materials |

Available Post-processing |

|

Selective Laser Melting |

$$$ |

5 Days/7 Days |

420mm x 420mm x 450mm |

6 Types |

More than 10 types |

What is aluminum 6061 in metal 3D printing?

Aluminum 6061 is a popular material in metal 3D printing due to its excellent mechanical properties and versatility. It is an alloy that combines aluminum with magnesium and silicon, providing a good balance of strength, corrosion resistance and machinability. In metal 3D printing, especially using techniques such as selective laser melting (SLM) and binder jetting, 6061 aluminum can be used to produce lightweight, high-strength parts with complex geometries that are difficult to achieve using traditional manufacturing methods. Metal 3D printed 6061 aluminum parts are used in aerospace, automotive, and industrial applications where performance and weight are critical factors.

In our case, we used 6061 aluminum to create life-sized boots as a special prize for consumers who purchased Modelo beer.

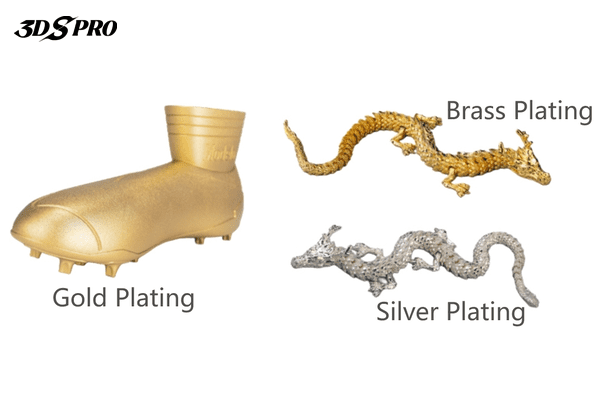

3D Printed Aluminum 6061 Boot After 24K Electroplated in Modelo Beer Campaign:

Mechanical Properties of Aluminum 6061

General Mechanical Properties of 3D Printing Aluminum 6061:

● Strength: Aluminum 6061 has good strength and is suitable for structural applications.

● Corrosion Resistance: Resists corrosion well, ideal for outdoor and marine environments.

● Weldability: Can be easily welded, allowing for further fabrication.

● Machinability: Easy to machine, which simplifies the manufacturing process.

● Thermal Conductivity: Has good thermal conductivity, useful for heat dissipation in various applications.

Our SLM 3D Printing Aluminum 6061 Mechanical Properties

|

Properties |

Data |

|

Hardness |

95HB |

|

Density |

2.8 g/cm³ |

|

Tensile Strength |

290MPa |

|

Elongation at Break |

10% |

|

Yield Strength |

240MPa |

*More information coming soon!

The Surface Finish of 3D Printed Aluminum 6061

1. Smoothness: The printed surface finish of 6061 aluminum is fairly smooth after sand blasting but may require more post-processing to achieve a highly polished appearance.

2. Layer Lines: As with most 3D printed metals, you may notice visible layer lines, which can be minimized with proper printing parameters and post-processing.

3. Surface Roughness: The surface roughness can vary depending on the orientation and parameters used during the printing process. In general, the roughness is better than that of another commonly used aluminum alloy, AlSi10Mg.

4. Post-Processing: Techniques such as sanding, bead blasting, or chemical polishing can significantly improve the surface finish, making it suitable for both functional and aesthetic applications.

5. Consistency: The surface finish is generally consistent across the entire part, which is critical for applications where consistency is required.

Applications of 3D Printing Aluminum 6061

● Aerospace: Lightweight structural parts, brackets, and housings that require high strength and corrosion resistance.

● Automotive: Components such as gearboxes, brackets, and heat sinks that benefit from Aluminum 6061's strength and thermal conductivity.

● Medical: Custom implants and surgical tools that need to be both strong and biocompatible.

● Electronics: Heat sinks and enclosures that require good thermal management and electrical conductivity.

● Industrial: Jigs, fixtures, and molds that benefit from Aluminum 6061's machinability and durability.

What are the main differences between Aluminum 6061 and AlSi10Mg?

|

Comparison Items |

Aluminum 6061 |

Aluminum AlSi10Mg |

|

Composition |

Aluminum, magnesium, and silicon. |

Aluminum with about 10% silicon and 1% magnesium. |

|

Strength |

Better balance of strength and ductility. |

Higher strength. |

|

Hardness |

Lower hardness but relatively easy to machine. |

Higher hardness. |

|

Corrosion Resistance |

Good corrosion resistance. |

Higher corrosion resistance. |

|

Thermal Conductivity |

Better thermal conductivity. |

Good thermal conductivity. |

|

Applications |

Structural applications, aerospace, and automotive industries due to its good mechanical properties and machinability. |

Applications where high strength-to-weight ratio and detailed features are required. |

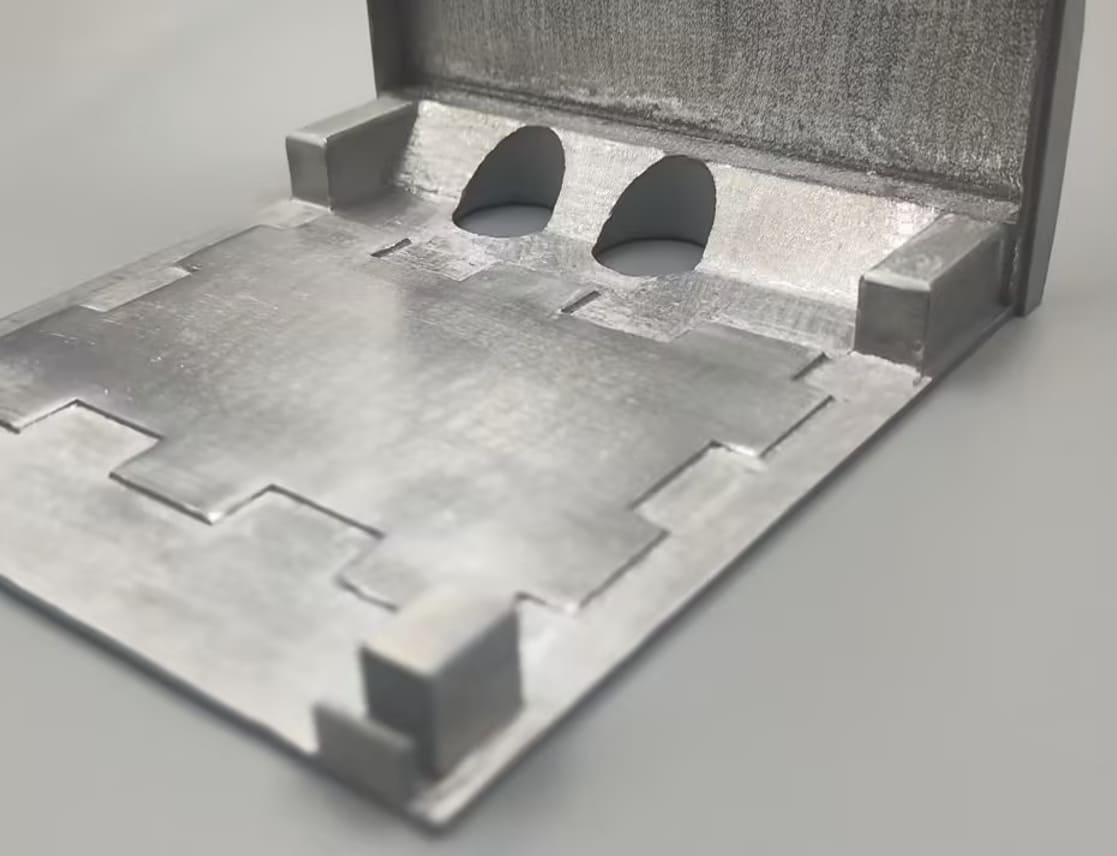

SLM 3D Printed AlSi10Mg Manifold:

Find out the Costs of Your 3D Printing Project and Try Our Aluminum 3D Printing Service

6061 3d printing