Introduction

3D printing, a marvel of modern technology, offers incredible opportunities for innovation across various sectors. As we are entering the brand new 2024, we see many new projects being initiated and planned, and 3D printing is going to be a key way for them to become reality. However, diving into the world of 3D printing requires not just creativity and technical know-how but also careful financial planning. Before embarking on your 3D printing journey, this article aims to guide you through the essentials of budget planning for 3D printing, ensuring that your investment reaps maximum benefits while keeping costs in check.

Assess Your Needs for 3D Printing

As the industry and technology grow, there are many different types of 3D printers now available for innovators to choose! The prices of them are ranging from $100+ to $100,000,000+. and making that purchasing decision can be more challenging than you expected. Ask yourself the following questions would be necessary before you start researching, because a clear objective can help you navigate through the process, and if you are answering NO to some of them or you are not quite sure about your answers, maybe owning a 3D printer is not the best choice for you.

Complexity and Quality Requirements

Will you be printing for simple projects or do you need professional-grade outputs? Will you be creating intricate designs requiring high resolution and precision? If so, investing in a printer with advanced capabilities, such as higher layer resolution and better temperature control, might be necessary.

Frequency

Do you need 3D printing for your project only occasionally or consistently? For a long-lasting project, the cost of buying a great printer may be worth it, while you may need to add more maintenance costs to your budget. If you plan to use 3D printing sporadically, perhaps for personal projects or hobbies, a basic desktop printer is usually sufficient. These printers are more affordable and cater to lower-frequency use without unnecessary features.

Volume

Will you be printing in large scale or you just need a few one? High-volume printing might necessitate a more durable printer with a larger build volume, while small batch 3D printing could be managed with a smaller, more cost-effective model.

Skill Level and Learning Curve

Do you or your teammates have the necessary skill set, time, energy, and patience to set up the machine and learn all the technical details of 3D printing? 3D printer, especially the advanced ones, are not quite easy to use, and there will usually be a learning curuve before you can achieve the best printing result. The cost of time and effort here can be hard to estimate.

If you answered NO or were not sure to those questions, 3DSPRO's 3D printing solutions and 3D Plus solutions can help you enjoy 3D printing in a hassle free way and avoid all the costs we mentioned before. We offer 5 different 3D printing technologies, 30+ materials, and 20+ post processing options to match all kinds of 3D printing demand. Our expert team will also be there assisting you through the whole process. Feel free to get an instant quote or contact us!

Understanding the types of 3D Printing and Estimate the Costs of 3D Printing

If you are thinking about having 3D printing capabilities in house, it’s crucial to understand that there are many different types of 3D printing technologies that you can use, and for each technology, there are different cost elements that need to be considered. In general, we see these 5 elements all technologies share, and they are pretty much always necessary.

Printer Costs: From affordable desktop models that prints rough toys, to high-end industrial machines that prints high detail parts with specialized materials, the price of 3D printers varies widely.

Material Costs

Just like the printers, there are affordable materials and specialized materials. Different printing technology use different materials. For desktop grade printers, it would be filaments like PLA, ABS, but for industrial grade printers, you will see resin, nylon, and even metal powders.

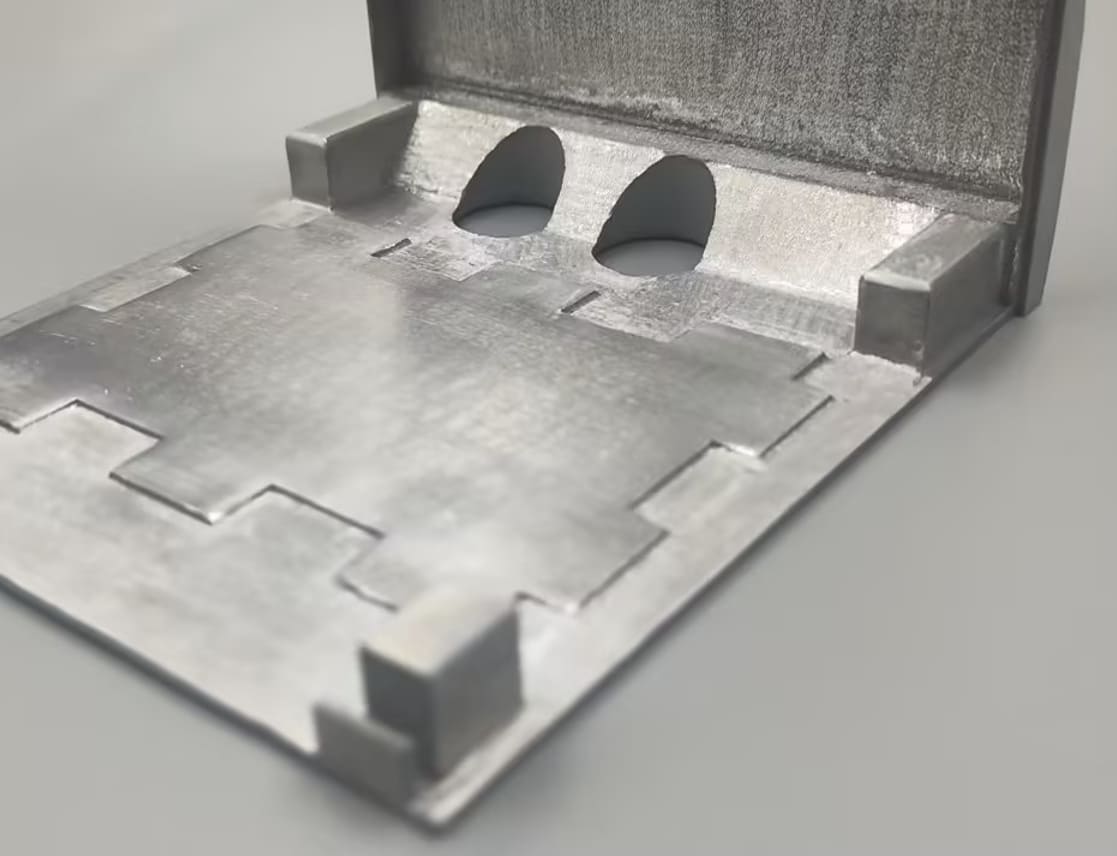

Post Processing Costs

Post processing is unavoidable for 3D printed products, even for the easiest one. Support removal, tapping and threading, polishing, painting, and even electroplating, those processes ensure the quality of your prints, but also bring extra costs to your project.

Maintenance and Upgrades

All 3D printers require regular maintenance and potential upgrades. Maintaining and upgrading a 3D printer is essential to ensure its longevity, reliability, and the quality of the prints it produces. These costs can vary depending on the type of printer, frequency of use, and the complexity of your projects. It would include but not limit to routine maintenance costs, material costs for maintenance, unforeseen repairs, etc.

Software Costs

Softwares can actually strongly affect the results of 3D printing, from designing models to slicing them into layers for the printer. Understanding and budgeting for these software costs is essential for a seamless and efficient 3D printing experience. While some softwares are free, more advanced design and slicing tools might require a subscription or one-time purchase.

Utility Costs

3D printing, while an efficient manufacturing process, does involve significant utility usage, primarily in terms of electricity, especially for prolonged use. Understanding and managing these costs is vital for both hobbyists and professionals. Environmental control costs may be incurred for both the production and post processing processes as well.

Training and Learning

If you and your company are new to 3D printing, there might be costs associated with courses or training materials, such as in-person workshops and seminars, online courses and certifications, books and e-books, membership fees, etc. There will also be labor costs whether if you are spending time and energy to work on 3D printing by yourself, or if you are paying your team to learn it.

Opportunity Costs

You only live once and time is a very constrained resource for everyone. If you are spending time and effort to get into 3D printing, you might be missing the opportunity to do other projects. Although we all love 3D printing and are believing the future of it here at 3DSPRO, it still might not be the best option for your project, and the opportunity cost is something you need to consider, especially when you are comparing it with another manufacturing technology.

Conclusion

Budget planning for 3D printing is a balancing act between cost, quality, and need. By understanding the various expenses and planning accordingly, you can make 3D printing a viable and financially rewarding venture. Whether you're a hobbyist or a professional, smart budgeting is key to unlocking the full potential of this transformative technology.

COMMENTS

- Be the first to share your thoughts!