What is SLS 3D printing?

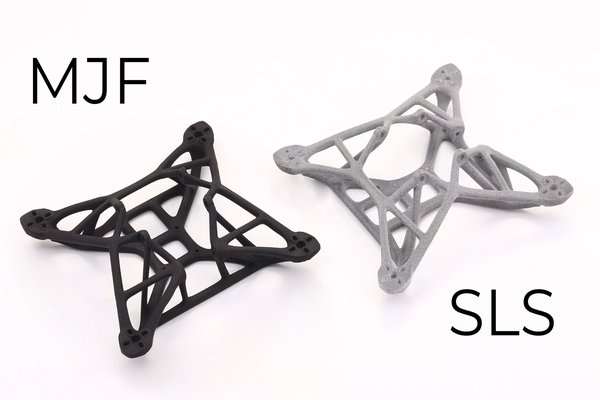

Selective Laser Sintering (SLS) 3D printing constructs objects by fusing powdered material layer by layer with a laser. The term "selective" refers to the precision with which the laser targets and sinters the powder, transforming it into solid structures based on a digital blueprint.

How SLS Works

1. Preparation: A thin layer of thermoplastic polymer powder is spread across the build platform.

2. Sintering: A high-powered CO2 laser selectively fuses the powder particles, tracing the cross-section of the object.

3. Layering: After each layer is sintered, the build platform lowers, and a new powder layer is applied.

4. Repetition: The process repeats until the object is fully formed.

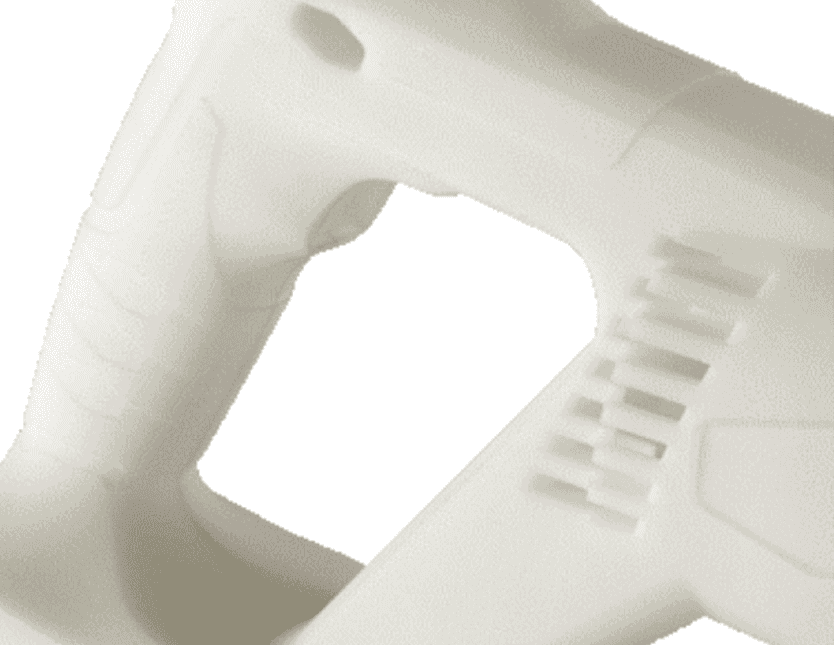

SLS 3D printing stands out for its ability to produce parts with complex geometries and internal features that would be challenging or impossible to achieve with traditional manufacturing methods. It's particularly valued for its design freedom, strength, and durability of the printed parts.

In the upcoming sections, we'll delve into the advantages and disadvantages, the materials used, the performance and applications of parts, and the online SLS 3D printing service.

SLS 3D Printing Pros and Cons

Selective Laser Sintering (SLS) 3D printing is a game-changer in additive manufacturing, offering a unique set of advantages and challenges.

Pros

Complex Designs Without Support: One of the most significant advantages of SLS is its ability to create complex geometries without the need for support structures. The powder bed itself supports the part during printing, allowing for intricate designs with overhangs and internal features.

Strong, Functional Parts: Parts produced by SLS are known for their strength and functionality. The laser sintering process results in excellent mechanical properties and isotropic strength, making SLS-printed parts suitable for functional prototypes and end-use applications.

Efficient Material Use: SLS is efficient in its use of materials. The unsintered powder acts as a support and can be reused for future prints, reducing waste and cost.

Post-Processing Flexibility: Post-processing options for SLS parts are abundant. From sandblasting to sealing and painting, these processes can enhance the aesthetic and functional properties of the printed parts.

Cons

Surface Finish: While SLS parts are strong, they typically have a slightly rough surface finish due to the nature of powder sintering. Achieving a smooth surface requires additional post-processing, such as sanding or tumbling.

Residual Powder Removal: After printing, parts must be cleaned to remove excess powder. This process can be time-consuming and may require specialized equipment.

Limited Material Options: Although SLS technology has expanded its material repertoire, it still offers fewer options compared to other 3D printing methods. This limitation can impact the selection process for specific applications.

Post-Processing Time: The need for post-processing, such as removing residual powder and improving surface finishes, adds time to the overall production process.

In summary, SLS 3D printing can produce complex, durable parts without support structures. However, considerations around surface finish, post-processing, and material limitations are essential when choosing SLS for a project.

SLS Printing Materials

Nylon Variants

PA 12: The workhorse of SLS materials, PA 12 is known for its excellent mechanical properties, high detail resolution, and good chemical resistance. It’s suitable for a wide range of applications, from complex hinges to high-endurance parts.

PA 11: Sourced from renewable resources, PA 11 offers similar qualities to PA 12 but with enhanced flexibility and impact resistance, making it ideal for parts requiring flexibility and strength.

PA 6: This material is chosen for its higher thermal resistance and strength, suitable for under-the-hood automotive applications or parts exposed to higher temperatures.

Filled Nylons

Glass-Filled Nylon: By adding glass beads or fibers to nylon powder, the material’s stiffness and thermal properties are significantly improved, which is crucial for functional parts that must endure stress and heat.

Aluminum-Filled Nylon: Integrating aluminum powder enhances the material’s thermal conductivity and stiffness, making it suitable for heat sinks and other thermally conductive parts.

Polystyrene (PS)

Often used for creating detailed models and prototypes, PS can be easily sanded and painted, making it a favorite for aesthetic models and investment casting patterns.

Thermoplastic Elastomers (TPE)

TPEs in SLS printing allow for the creation of flexible and rubber-like parts, expanding the range of possible applications to include gaskets, seals, and soft-touch components.

High-Performance Polymers

Polyetherketone (PEK) and Polyaryletherketone (PAEK): These high-performance polymers are known for their exceptional thermal and chemical resistance, suited for demanding environments like the aerospace and automotive industries.

Polycarbonate (PC)

PC is valued for its high strength and transparency, making it suitable for functional parts that need to be both durable and visually clear.

Specialty Materials

Flame Retardant: Certain SLS materials are designed to be flame retardant, meeting specific industry standards for safety.

Conductive: There are also conductive materials available, opening up possibilities for creating parts with integrated electrical functionality.

Each of these materials brings a unique set of properties to the table, allowing engineers and designers to choose the perfect match for their specific needs.

Part Performances and Applications

Selective Laser Sintering can produce parts with excellent mechanical properties, making it a preferred choice for a wide range of applications across various industries.

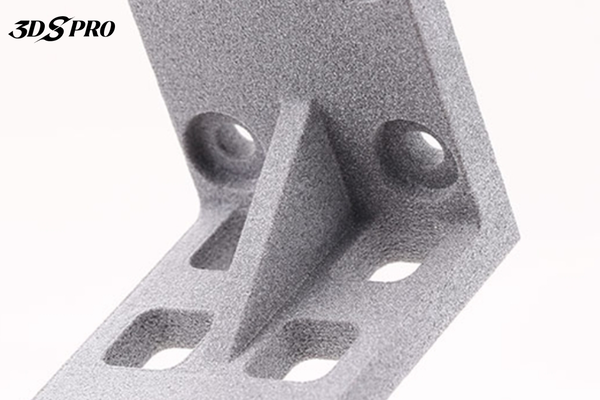

SLS parts are characterized by their good, isotropic mechanical properties, which means they have uniform strength in all directions. It is due to the layer-by-layer sintering process that fuses the powder particles into a solid, cohesive structure. The materials used, such as nylon and its composites, contribute to the parts’ durability, making them suitable for functional prototypes and end-use components.

The robustness of SLS parts makes the technology ideal for a variety of applications. It is commonly used for functional proof of concept models, design evaluation models (form and fit), engineering design verification, and product performance and testing. SLS is also perfect for rapid prototyping, as it can produce parts with complex geometries and intricate details that are difficult to achieve with traditional manufacturing methods.

SLS prototypes and end parts are utilized across multiple sectors, including aerospace and defense for manufacturing lightweight and complex parts for spacecraft, satellites, and military equipment. The automotive industry uses SLS to produce customized parts and prototypes for vehicles. In the medical field, SLS is employed to create bespoke prosthetics, dental implants, and other healthcare devices.

SLS Printing Service

When it comes to bringing your designs to life, Selective Laser Sintering (SLS) printing services are a cornerstone of rapid prototyping and production. 3DSPRO offers comprehensive online SLS 3D printing services.

The journey from design to physical part is streamlined with 3DSPRO’s online platform. You can upload your 3D model files and receive an instant quote, making the process efficient and transparent.

Beyond printing, 3DSPRO’s 3D Plus™ solutions are designed to enhance the quality and functionality of your parts. Such as:

Vapor Smoothing: Vapor smoothing is a post-processing technique that creates a sealed and aesthetically pleasing exterior for parts that require a smoother finish. It is particularly beneficial for parts intended for consumer use or customized medical devices.

Dyeing: 3DSPRO offers dyeing services to add vibrant colors to your parts. The dye penetrates the porous surface of the SLS-printed parts, providing a uniform color that enhances their visual appeal without compromising mechanical properties.

Threading and Tapping: To ensure your parts are ready for assembly, 33DSPRO 3D+ Solutions offers threading and tapping for your parts. It allows for the integration of screw threads, making the parts compatible with standard hardware components.

We are dedicated to delivering a full spectrum of services that cater to the needs of innovators and creators, ensuring that every aspect of the 3D printing process is covered with precision and care. Whether you’re looking to prototype a new idea or produce parts at scale, 3DSPRO’s SLS service is equipped to support your project from start to finish.

COMMENTS

- Be the first to share your thoughts!