3D Printing Specialty Resins

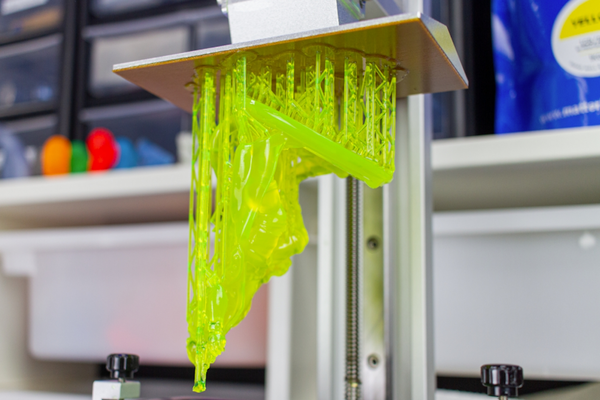

In resin-based 3D printing, standard resins are widely used for prototyping and hobbyist projects, while specialty resins unlock advanced applications across industries such as jewelry, aerospace, healthcare, and electronics. These resins are engineered with unique properties, whether it’s elasticity, heat resistance, or biocompatibility, that allow designers and engineers to push the boundaries of what’s possible.

In this article, we’ll explore the most important specialty resins and their applications.

Castable Resin

3DSPRO provides Castable Wax Resin for resin 3D printing service >>

Castable resin is the go-to material for investment casting. It burns out cleanly without leaving ash or residue, making it ideal for creating molds used in jewelry, dental prosthetics, and small-scale industrial parts.

Key Features:

• Clean burnout during casting.

• High detail resolution for intricate designs.

• Smooth surface finish.

Applications:

• Jewelry design: rings, pendants, and custom pieces.

• Dental crowns and bridges.

• Small mechanical components require precision casting.

Elastic Resin

3DSPRO provides Elastic 50A Resin for resin 3D printing service >>

Elastic resin mimics the properties of soft rubber, offering high flexibility and resilience. Unlike rigid resins, it can bend, compress, and stretch without breaking.

Key Features:

• High elongation at break.

• Soft, rubber-like feel.

• Durable under repeated stress.

Applications:

• Wearables such as straps and cushioning pads.

• Medical devices require flexibility.

• Prototypes of consumer products like grips and seals.

Flexible Resin

3DSPRO provides Flexible 80A Resin for resin 3D printing service >>

Flexible resin is often confused with elastic resin, but it offers a distinct balance between rigidity and pliability. It is less stretchy than elastic resin but provides impact resistance and shock absorption.

Key Features:

• Moderate flexibility with toughness.

• Smooth surface finish.

• Good dimensional accuracy.

Applications:

• Protective cases and housings.

• Seals, gaskets, and cushioning components.

• Consumer electronics prototypes.

Flame Retardant Resin

3DSPRO provides Flame Retardant Resin for resin 3D printing service >>

Safety-critical industries such as aerospace and automotive demand materials that resist ignition. Flame retardant resin is engineered to meet these requirements, offering compliance with fire safety standards. By reducing fire risks, flame retardant resin ensures that 3D printed parts can be safely integrated into environments where safety regulations are strict.

Key Features:

• Self-extinguishing properties.

• High thermal stability.

• Certified for safety-critical applications.

Applications:

• Aerospace interior components.

• Automotive parts near heat sources.

• Electrical housings and connectors.

ESD Resin

3DSPRO provides ESD Resin for resin 3D printing service >>

Electrostatic discharge (ESD) can damage sensitive electronics. ESD resin is formulated to dissipate static electricity, protecting delicate circuits during assembly and use. ESD resin is indispensable in electronics manufacturing, where even a small static shock can destroy expensive components.

Key Features:

• Controlled surface resistivity.

• Prevents static buildup.

• Durable and dimensionally stable.

Applications:

• Jigs and fixtures for electronics assembly.

• Casings for circuit boards.

• Tools used in semiconductor manufacturing.

High-Temp Resin

3DSPRO provides High-Temp Resin for resin 3D printing service >>

High-temperature resin withstands extreme heat without deforming, making it essential for functional testing and industrial applications. It allows engineers to prototype parts that must endure harsh conditions, reducing the need for costly metal prototypes.

Key Features:

• Heat deflection temperatures exceeding 200°C.

• High stiffness and dimensional stability.

• Resistant to thermal cycling.

Applications:

• Mold inserts for injection molding.

• Automotive and aerospace testing parts.

• Components exposed to high-heat environments.

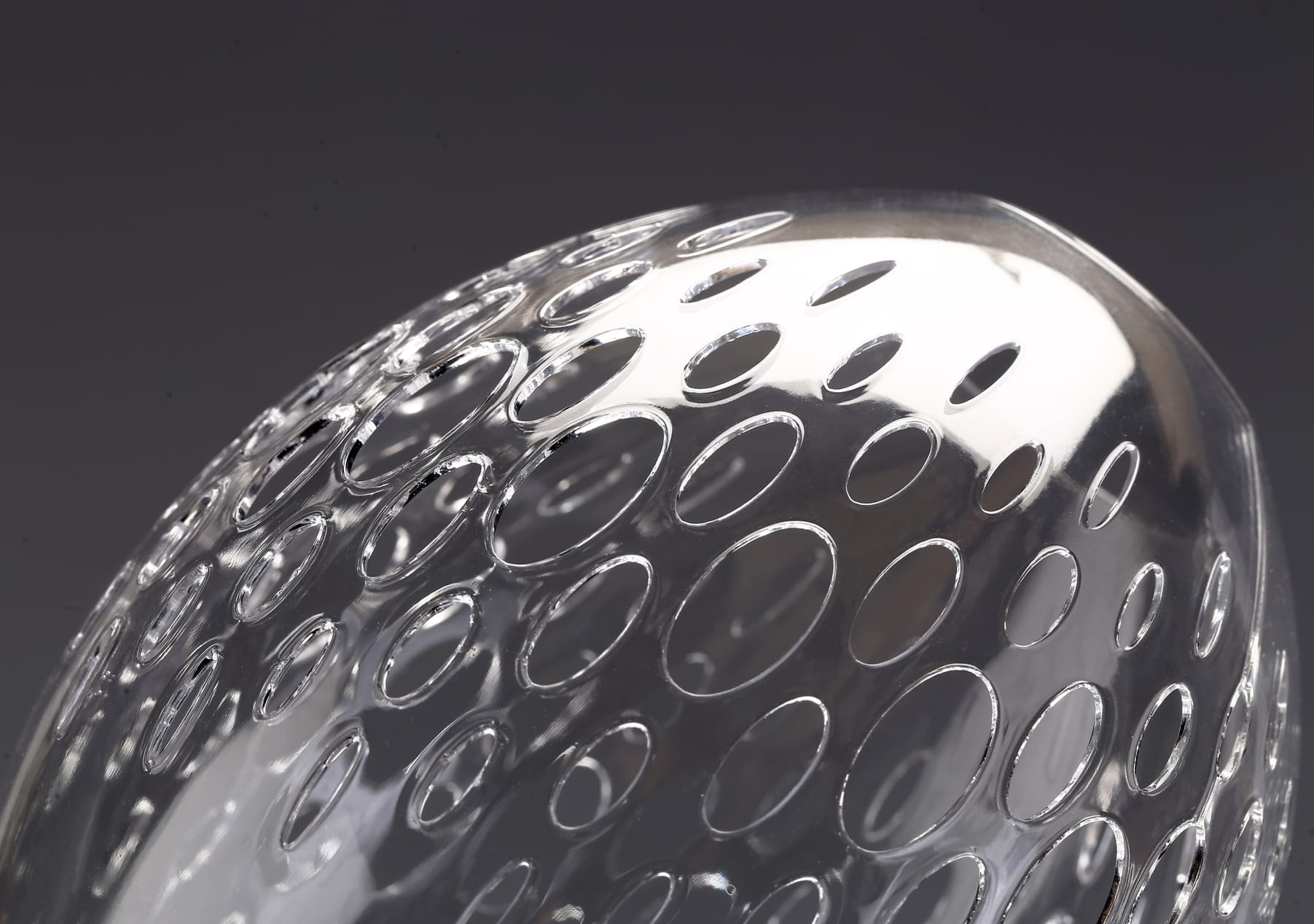

Mold Resin

3DSPRO provides Precision Mold Resin for resin 3D printing service >>

Mold resin is designed for creating reusable molds for casting silicones, waxes, or other materials. It combines durability with fine detail reproduction, empowering creators to produce short-run products without investing in expensive tooling.

Key Features:

• High tear strength.

• Smooth surface finish.

• Resistant to repeated casting cycles.

Applications:

• Custom molds for small-batch production.

• Prototyping consumer goods.

• Artistic applications, such as sculpture casting.

Bio-Compatible Resin

Bio-compatible resin is certified for medical and dental use, ensuring safety when in contact with the human body. It is revolutionizing healthcare by enabling patient-specific solutions, from dental aligners to surgical planning tools.

Key Features:

• ISO and FDA certifications for biocompatibility.

• Sterilizable via autoclave or chemical methods.

• High accuracy for medical applications.

Applications:

• Surgical guides.

• Dental models and prosthetics.

• Custom medical devices.

3DSPRO Resin 3D Printing Services

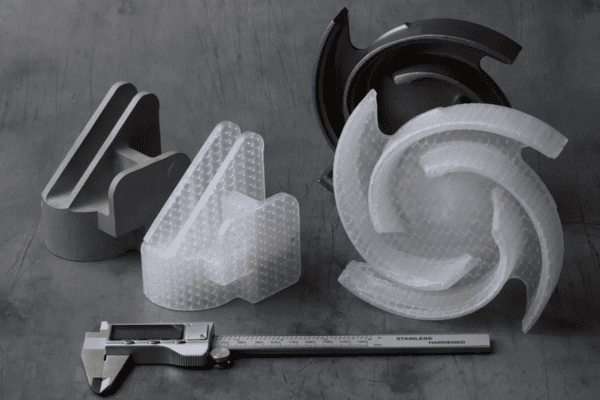

While specialty resins open new possibilities, their full potential is realized through professional-grade printing services. We offer advanced resin printing technologies, including SLA, LCD, and DLP 3D printing services, that ensure precision, reliability, and scalability.

• Uses a laser to cure resin layer by layer.

• Delivers exceptional accuracy and smooth surfaces.

• Ideal for prototypes requiring fine detail.

• Employs an LCD screen with UV light to cure resin.

• Faster and more cost-effective for batch production.

• Suitable for consumer products and rapid prototyping.

DLP (Digital Light Processing):

• Projects light patterns to cure entire layers at once.

• Offers speed and efficiency for industrial-scale projects.

• Perfect for applications requiring both detail and throughput.

By combining specialty resins with these technologies, 3DSPRO enables businesses and creators to bring their visions to life, whether it’s a flame-retardant aerospace component, a dental mold, or a castable jewelry prototype.

Image Source: Formlabs

COMMENTS

- Be the first to share your thoughts!