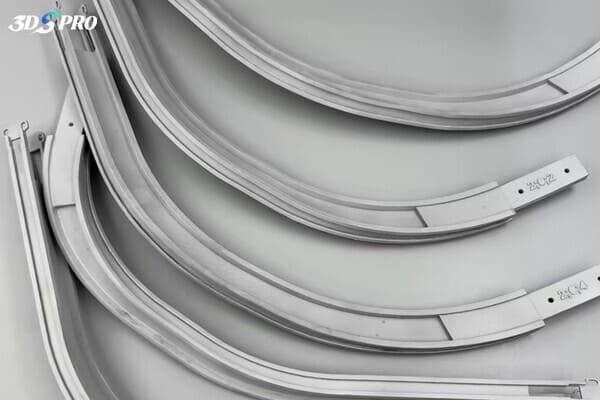

Q4 2025 is an Important Timing for 3D Printing

The final quarter of the year is always a high‑pressure environment for businesses. Whether you’re driving year-end sales, preparing for the holiday rush, or closing out a production cycle, agility and speed are key.

In the fourth quarter of 2025, the need for rapid innovation will be even more prominent due to evolving customer expectations, accelerating product cycles, and tight supply chain timelines.

3D printing is emerging as a leading solution to these challenges. Unlike traditional manufacturing, which often requires long lead times and large minimum order quantities, custom 3D printing enables businesses to produce high-quality, fully functional parts or prototypes on demand. With the rapid maturation of the 3D printing service market, even small and medium-sized businesses can now achieve industrial-scale production without significant capital investment.

Image Source: Auto Tech

Rapid Prototyping for Year End Product Launches

The holiday season is prime time for product launches, limited editions, and promotional items. However, late‑stage design changes or unexpected delays can derail schedules.

With 3D printing, you can:

• Produce functional prototypes within days instead of weeks.

• Test, tweak, and finalize designs at record speed.

• Launch products on time, even with last‑minute modifications.

For example, a consumer electronics company can iterate through multiple casing designs in October and still have production‑ready parts for a November launch. The agility of custom 3D printing ensures you’re not sacrificing innovation for speed.

Bridge Manufacturing for Supply Chain Gaps

Global supply chains remain unpredictable, with shipping delays, material shortages, and geopolitical factors causing disruptions. 3D printing services offer an effective bridge manufacturing strategy, allowing you to fill temporary production needs while awaiting traditional manufacturing runs.

Key benefits for Q4:

•Small‑batch production to meet sudden demand spikes.

• Avoid lost sales due to out‑of‑stock inventory.

• Reduce dependency on overseas suppliers for urgent parts.

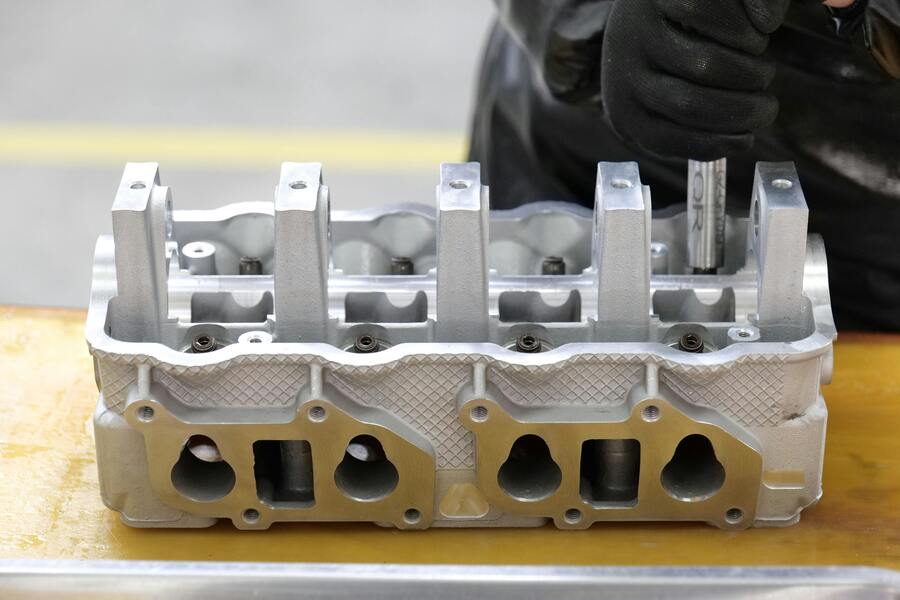

For industries like automotive and aerospace, this approach can keep production lines moving while awaiting bulk deliveries, especially critical before the fiscal year closes.

Image Source: Auto Tech

Custom Seasonal Products

Seasonal products, especially personalized ones, tend to perform exceptionally well during the holiday season. With custom 3D printing, you can create short‑run or one‑off products that resonate with customers.

Applications include:

• Personalized ornaments, jewelry, or tech accessories.

• Limited‑edition packaging or decorative components.

• Co‑branded merchandise with quick turnaround.

Because 3D printing services remove tooling costs, businesses can afford to experiment with niche designs without risking overproduction.

Spare Parts & Maintenance Before Year End

Q4 is also the time when many companies push to close maintenance backlogs, ensuring equipment is in top shape for the new year. Waiting for spare parts from suppliers can lead to costly downtime.

3D printing enables:

• On‑demand production of replacement parts, even for discontinued equipment.

• Cost‑effective runs for low‑volume, high‑value components.

• Reduced lead times from weeks to days.

By using custom 3D printing, maintenance teams can ensure operational readiness heading into 2026.

Image Source: Auto Tech

Selecting the Right Technology and Services Provider

Choosing the right partner for your 3D printing services is critical for maximizing results. 3DSPRO offers a comprehensive range of solutions tailored for Q4’s unique challenges:

|

Technologies |

How to Choose |

|

Ideal for high‑resolution, smooth‑surface parts and detailed prototypes. |

|

|

Strong, functional parts without support structures. |

|

|

Fast, precise production of durable parts at scale. |

|

|

High‑performance metal parts for industrial applications. |

|

|

Professional finishing, coloring, and surface treatments to make parts production‑ready. |

Q4 2025 presents unique opportunities and challenges. From rapid prototyping and bridge manufacturing to seasonal customization and urgent maintenance, 3D printing offers a versatile toolkit for staying competitive. By partnering with the right provider, you can turn last‑minute demands into market advantages and enter 2026 with momentum.

COMMENTS

- Be the first to share your thoughts!