From the choice of filament or resin to the nuances of part geometry, every decision you make—from selecting PLA, ABS, PETG, resin, nylon, PP, or metal to optimizing your design for strength—directly impacts how long your prints will endure. Beyond material and design, the finishing touches of post-processing and the environment in which your parts live—whether exposed to UV, moisture, or mechanical stress—play critical roles in determining their useful life.

Material Selection

|

Material |

Pros |

Cons |

|

PLA |

•Biodegradable • Easy to print • Minimal warping |

• Brittle • Poor UV & heat resistance |

|

ABS |

• Good toughness • Moderate heat resistance (≈ 80 °C) |

• Prone to warping • Emits fumes during print |

|

PETG |

• Excellent layer adhesion • Chemical resistance • Flexibility |

• Tendency to string if not tuned |

|

Resin |

• High-detail finish • Engineering grades add toughness |

• Standard resins are brittle • Requires UV cure |

|

Nylon |

• Outstanding impact & fatigue resistance |

• Hygroscopic (needs drying) • More challenging print |

|

PP |

• Excellent chemical & fatigue resistance |

• Poor bed adhesion • Needs specialty build surface |

|

Metal* |

• Exceptional strength & temperature stability |

• Higher cost • Longer lead times |

Metal* Via DMLS/MJF in stainless steel, aluminum, or titanium.

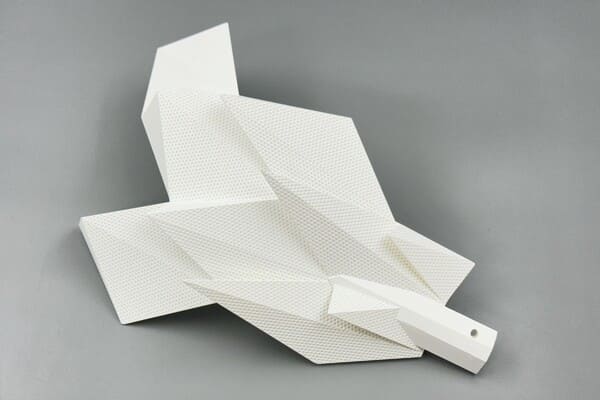

Part Design

1. Wall Thickness & Infill Density: Thicker walls (≥2 mm) and infill ≥50% boost structural integrity but raise print time and material use.

2. Fillets & Chamfers: Rounded transitions distribute stress more evenly than sharp corners, reducing crack initiation.

3. Layer Orientation: Align layers so that the primary load direction runs parallel to layer lines, minimizing delamination risk.

4. Avoid Stress Concentrators: Abrupt geometry changes and thin bridges can become failure hotspots under cyclic loads.

Thoughtful design ensures your custom 3D printed parts endure real‑world stresses.

Photo Copyright © Batten and Kamp. All rights reserved.

Post Processing & Finishing

Annealing

Heating PLA or PETG parts above their glass transition temperature relieves internal stresses, improving toughness.

Coatings & Sealants

Applying epoxy, polyurethane, or UV‑resistant varnishes adds a protective barrier against moisture, chemicals, and sunlight.

Vapor Smoothing (Nylon)

Acetone vapor treatment fuses layer lines, increasing impact resistance and water tightness.

Beyond aesthetics, certain pigments block UV rays, slowing degradation.

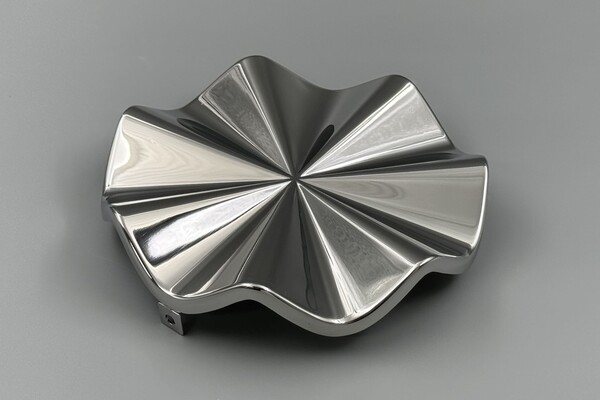

Mechanical Finishing (for Metals)

Polishing, bead blasting, sandblasting, anodizing, passivation, etc., reduce surface roughness, inhibiting crack initiation in high‑stress environments.

3DSPRO’s in‑house finishing suite ensures each part meets your durability requirements.

Photo Copyright © 3DSPRO. All rights reserved.

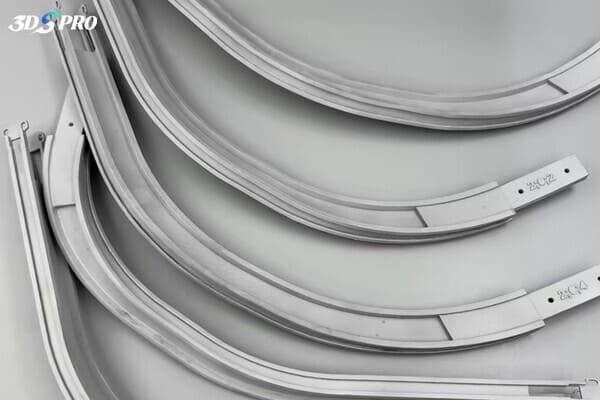

Environmental Condition

UV Exposure

PLA, many resins, and non‑UV‑stabilized polymers chalk and weaken under constant sunlight. UV‑resistant coatings or UV‑stable materials (e.g., ASA, PETG) help.

Temperature Extremes

Continuous exposure above a material’s glass transition temperature (e.g., PLA > 60 °C) leads to creep and deformation. Metal prints excel in both heat and cold.

Humidity & Chemicals

Hygroscopic polymers like Nylon absorb moisture, becoming softer and less dimensionally stable. Chemical‑resistant materials such as PP or PETG combat harsh solvents.

Mechanical Wear

Bearings, hinges, and gear teeth face fatigue. Engineering resins and Nylon with high infill resist repetitive cycles.

Matching material choice and finish to operating conditions maximizes 3D print lifespan.

Photo Copyright © 3DSPRO. All rights reserved.

Expected Lifespans by Material

Use this reference to set realistic expectations for your parts’ service life:

|

Material |

Average Lifespan* |

|

PLA |

1–3 years |

|

ABS |

3–5 years |

|

PETG |

5–10 years |

|

Standard Resin |

2–4 years |

|

Engineering Resin (Tough/Flex) |

4–8 years |

|

Nylon* |

7–12 years |

|

Polypropylene (PP) |

8–15 years |

|

Metal (Stainless, Aluminum, Titanium) |

20+ years |

Average Lifespan* assumes typical indoor use and proper storage.

Nylon* assumes proper drying before print and moisture‑controlled storage.

Why Choose 3DSPRO for Long Lasting 3D Prints

When durability is non‑negotiable, 3DSPRO’s custom 3D printing services deliver:

1. Comprehensive Material Library

From more than 10 types of resins to industrial-grade Nylon, PP, and metal alloys, we match the right substrate to your application’s lifespan targets.

2. Multi‑Technology Capabilities

SLA for high‑detail components, SLS/MJF for functional strength, and SLM for metal‑grade performance.

We offer more than 20 types of surface finishing services, which are called 3D Plus™ services; learn more >>

Dimensional metrology, mechanical stress testing, and accelerated aging simulations validate your parts before they ship.

Instant quoting, comparative pricing, and material filters empower you to balance cost against longevity seamlessly.

6. Dedicated Technical Support

Our engineers provide design reviews (DFAM) and material recommendations to ensure your custom 3D printed parts meet real‑world demands.

COMMENTS

- Be the first to share your thoughts!