High-performance titanium parts are revolutionizing industries from aerospace to medical devices. If you’re looking for reliable, custom titanium 3D printing services, 3DSPRO has you covered. In this comprehensive guide, we’ll walk through everything you need to know about titanium 3D printing service, from pricing and lead times to surface finishing options and alternative titanium alloys beyond Ti64V.

Try Titanium 3D Printing Service at 3DSPRO

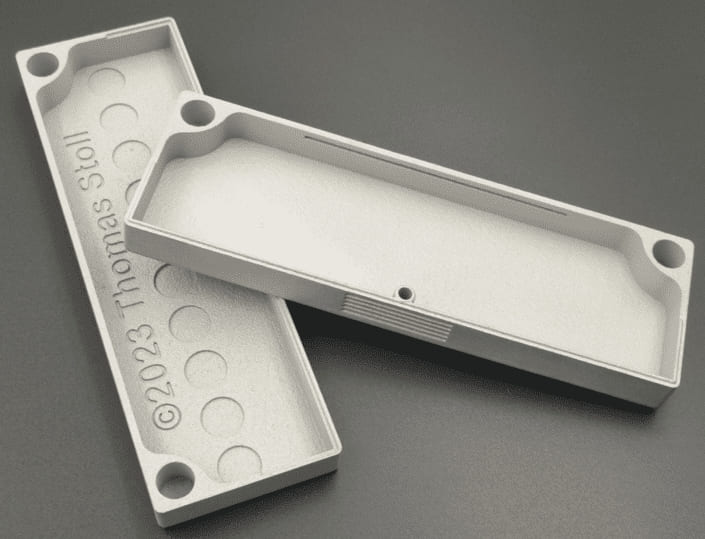

At 3DSPRO, our titanium 3D printing service leverages selective laser melting to deliver precision parts with exceptional mechanical properties. Here is our titanium 3D printing service:

1. Materials & Machines

We primarily use Ti6Al4V (Ti64V) powder in our laser powder bed fusion (SLM) systems, ensuring consistent layer adhesion and optimal density.

2. Minimum Lead Time

Standard lead time starts from 7 business days, depending on part complexity and order volume. Rush options are available for urgent projects.

Every batch undergoes rigorous inspection—3D scanning, dimensional checks, and mechanical testing—to guarantee compliance with aerospace and medical standards.

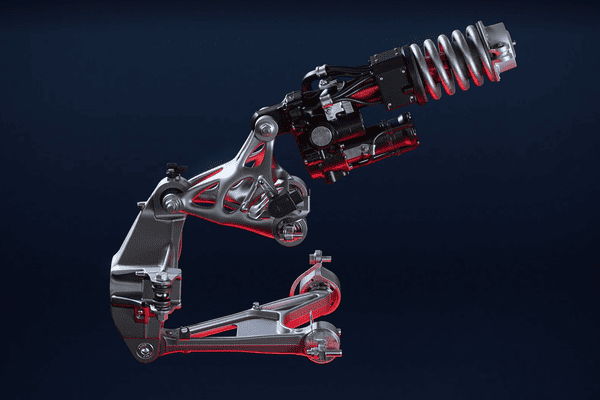

4. Custom 3D Printing Services

Whether you need one prototype or a small production run of 3D printed titanium parts, we tailor our workflow to your design files.

You can choose from a comprehensive range of post‑processing finishes to meet both functional and aesthetic requirements. Whether you need corrosion‑resistant electrocoating, durable powder coating or spray painting in custom colors, or precision tumbling and polishing—including mirror polishing for ultra‑smooth surfaces—our team can tailor the exterior to your specifications.

For textured finishes, we provide sandblasting or glass‑bead blasting, and for parts that require markings or branding, we offer screen printing.

We also handle mechanical enhancements like tapping and threading and can even weld multi‑component assemblies, ensuring that every 3D printed titanium component is ready to install straight from our facility.

Our in-house engineers assist with design for additive manufacturing (DfAM), suggesting support structures, orientation, and hollowing strategies to optimize cost and performance.

Photo Copyright © 3DSPRO. All rights reserved.

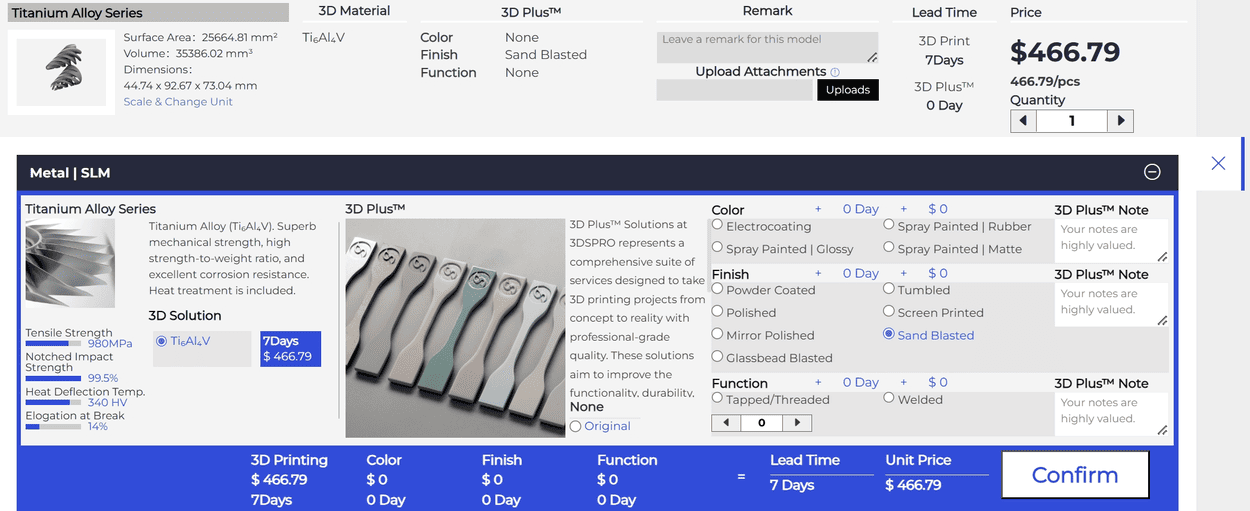

Price of 3D Printed Titanium Parts

Material Consumption

Ti64V powder costs more than common plastics. Expect material costs in the range of $200–$400 per kilogram, depending on market rates and powder grade.

Build Volume & Machine Time

Machine hourly rates typically range from $80 to $150. More intricate builds or multiple parts in a single job will increase total machine time.

Post‑Processing

Standard stress relief and heat treatment are included, but additional machining, surface finishes, and inspections add to the cost.

Order Size

Volume discounts apply for bulk runs. Prototypes (1–5 units) carry a higher per‑unit price compared to small series (10–50 units).

Design Complexity

Parts requiring extensive supports, intricate geometries, or tight tolerances may incur extra setup fees.

Ballpark Estimate: For a moderately complex titanium part (~100 cm³), expect pricing between $800 and $1,500 per unit, inclusive of basic post‑processing. Always request a quote with your specific CAD file to get an accurate price tailored to your needs.

3D Printing Titanium Cost Example at 3DSPRO:

3D Printed Titanium Lead Time

|

Process Step |

Duration |

|

Design for AM Review |

1–2 business days |

|

File Preparation & Nesting |

1 business day |

|

Printing (Selective Laser Melting) |

2–4 business days |

|

Stress Relief & Heat Treat |

1–2 business days |

|

Surface Finishing* |

1–3 business days |

|

Quality Inspection & Packing |

1 business day |

|

Total |

From 7 business days |

Surface Finishing* Depending on chosen finishes; see Part 4 for details.

Photo Copyright © 3DSPRO. All rights reserved.

Rush manufacturing and expedited inspection services are available to meet deadlines for critical applications.

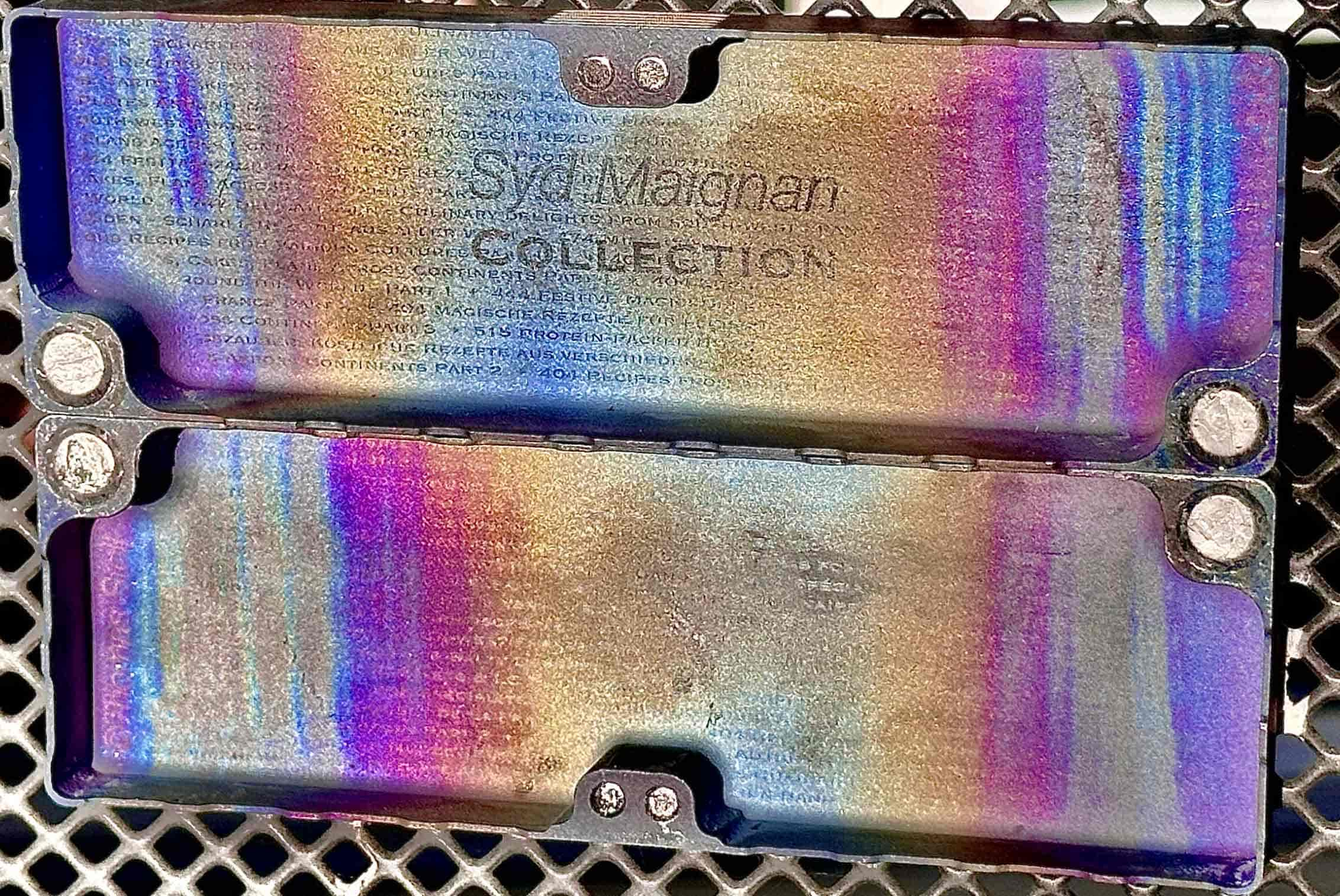

What Surface Finishes I Can Choose for 3D Printed Titanium Parts

To tailor 3D printed titanium parts to your application—whether for aesthetic, functional, or biocompatibility reasons—3DSPRO offers a full suite of surface finishing services:

|

Surface Finish |

Advantages |

|

Colorful, durable and uniform finish |

|

|

Corrosion resistance and even coating thickness |

|

|

Custom colors and branding |

|

|

Durable, uniform finish |

|

|

Deburr and smooth rough edges |

|

|

Polishing & Mirror Polishing |

Low surface roughness (Ra < 0.2 µm) |

|

Logos, part numbers, or functional markings |

|

|

Create matte or satin textures |

|

|

Post‑print mechanical features |

|

|

Welding (TIG or laser) |

Assemble multi‑component structures |

Each finishing step is performed under controlled conditions to preserve dimensional tolerances and mechanical integrity. For detailed lead time of 3D printed titanium parts with surface finishing services, please upload your 3D files, click configure and choose Titanium Alloys and surface finishes bar.

Photo Copyright © 3DSPRO. All rights reserved.

Beyond Ti64, Which Other Titanium Alloys Are 3D‑Printable?

While Ti6Al4V (Ti64V) is the industry workhorse, several other titanium alloys are gaining traction in additive manufacturing:

1. Ti6Al4V ELI (Grade 23): Extra Low Interstitial variant for enhanced fracture toughness in medical implants.

2. Ti–6Al–7Nb: Niobium replaces vanadium for improved biocompatibility in orthopedic devices.

3. Ti–6Al–2Sn–4Zr–2Mo (Ti–6242): Higher temperature strength for aerospace turbine components.

4. Ti–5Al–5V–5Mo–3Cr (Ti–5553): Balanced strength and fracture toughness for landing gear parts.

5. Beta‑Titaniums (e.g., Ti–15Mo): Excellent formability and corrosion resistance for chemical‑processing equipment.

Printing titanium alloys successfully demands meticulous optimization of laser parameters and, in many cases, tailored post‑heat treatments to develop the precise microstructure and mechanical performance your part requires. Our materials experts are ready to help you select the ideal alloy and processing workflow for your application—just bear in mind that titanium is one of the more demanding metals to 3D‑print, requiring stringent process control.

FAQs

Q: How do I submit my design for a quote?

A: Upload your CAD file (STL, STEP, or IGES) via our online portal. Our quoting engine provides instant quotes.

Q: What tolerances can you achieve?

A: Standard tolerances are ±0.3 mm.

Q: Is support removal included?

A: Yes. Our pricing covers support structure removal, although extracting supports from intricate internal channels can be challenging.

COMMENTS

- Be the first to share your thoughts!