Governments, corporations, and communities are racing to decarbonize, scale renewable energy, and build infrastructure that can withstand the pressures of climate change. Solar, wind, hydrogen, and advanced storage systems are the backbone of tomorrow’s energy economy.

Yet, innovation in clean energy is often slowed by the realities of manufacturing. Traditional production methods struggle to keep pace with the speed of design iteration and the demand for highly customized, high-performance components. Tooling costs, long lead times, and material waste create bottlenecks that delay deployment and drive up costs.

Metal 3D printing changes the equation. By enabling rapid prototyping, complex geometries, and on-demand production, metal 3D printing accelerates the pace of clean energy innovation. It empowers startups and established players alike to move from concept to deployment faster, more sustainably, and with greater design freedom.

Through collaborations with innovators in solar, automotive, aerospace, and beyond, 3DSPRO has demonstrated how metal 3D printing can unlock new possibilities for the energy sector. One standout example is its partnership with Yotta Energy, a solar storage pioneer.

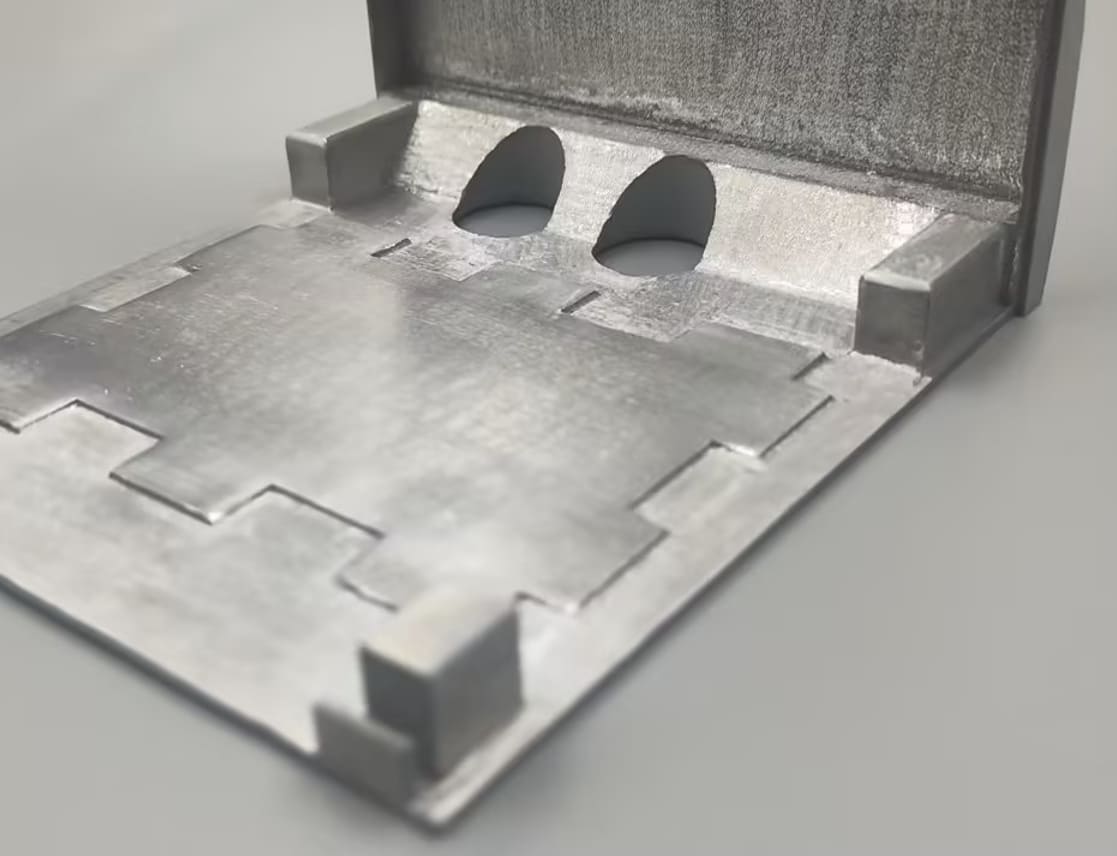

Image Copyright © 3DSPRO Limited. All rights reserved.

Case Study: Yotta Energy x 3DSPRO

Yotta Energy set out with a bold mission: to revolutionize solar energy storage by integrating battery systems directly into solar arrays. Their vision required components that were not only durable and precise but also manufacturable at speed to support rapid scaling.

Traditional manufacturing methods posed challenges. Producing custom chassis, gaskets, and spare parts through conventional machining or casting would have required expensive tooling and long lead times; such constraints could have slowed Yotta’s momentum in a fast-moving market.

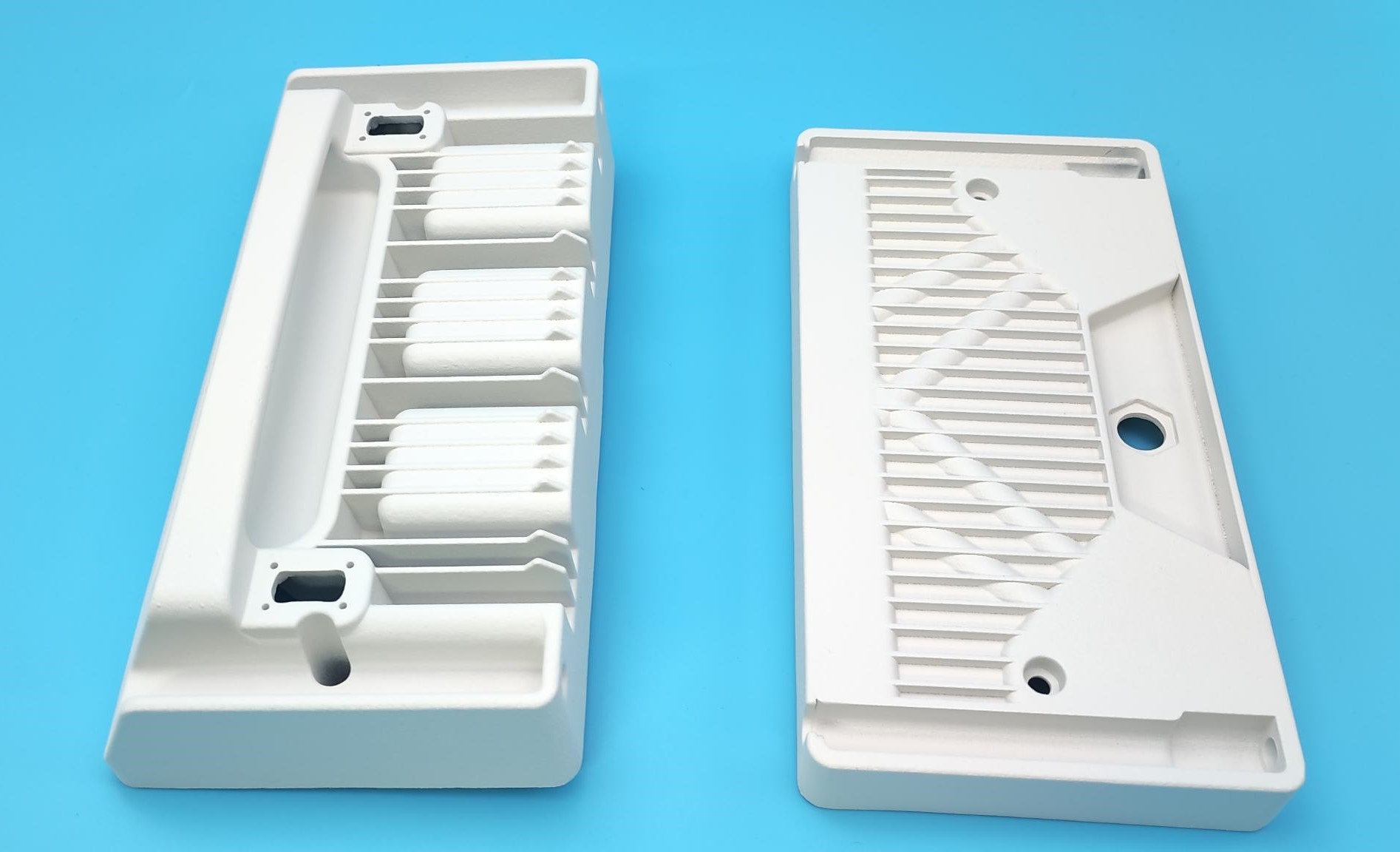

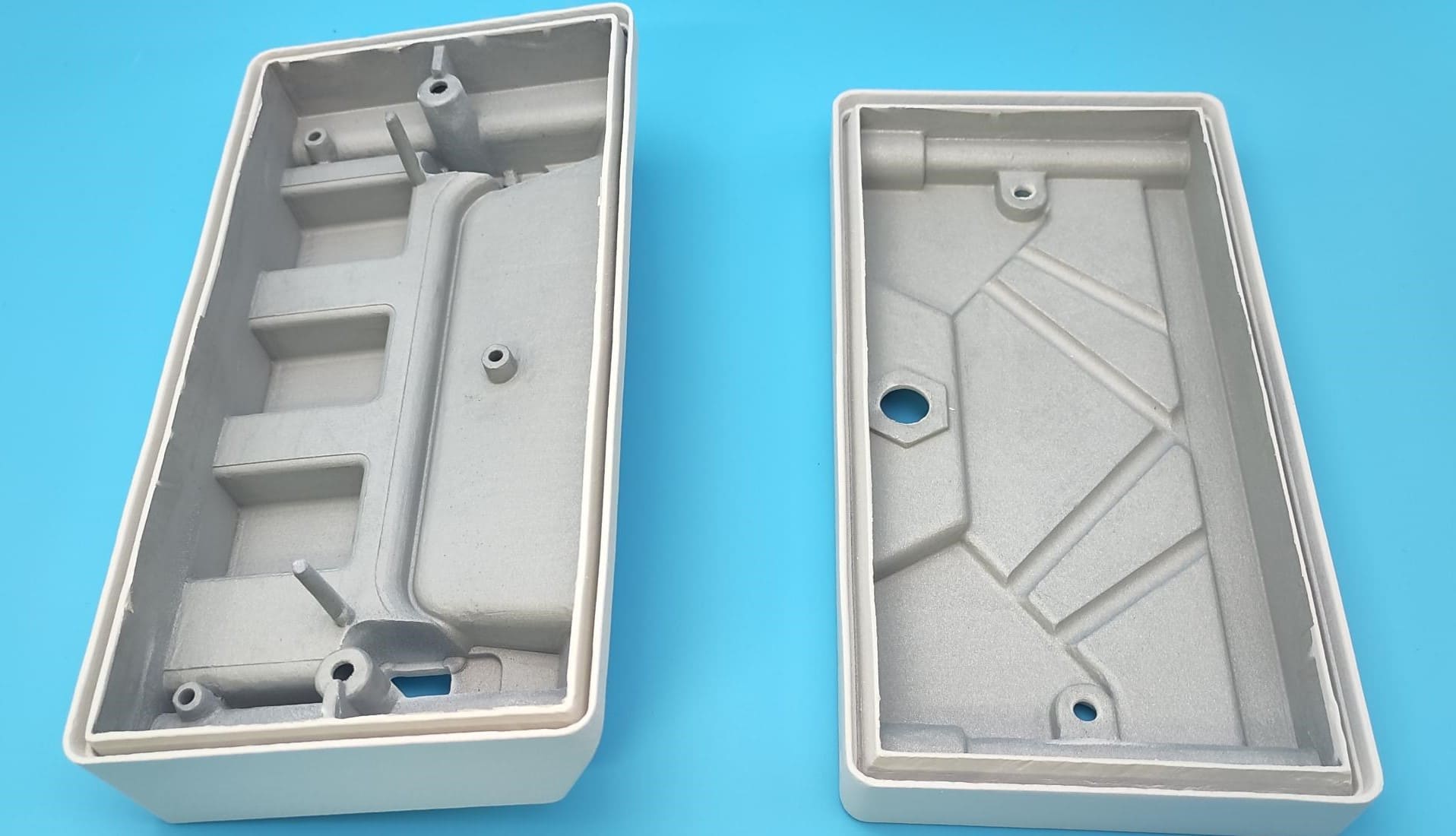

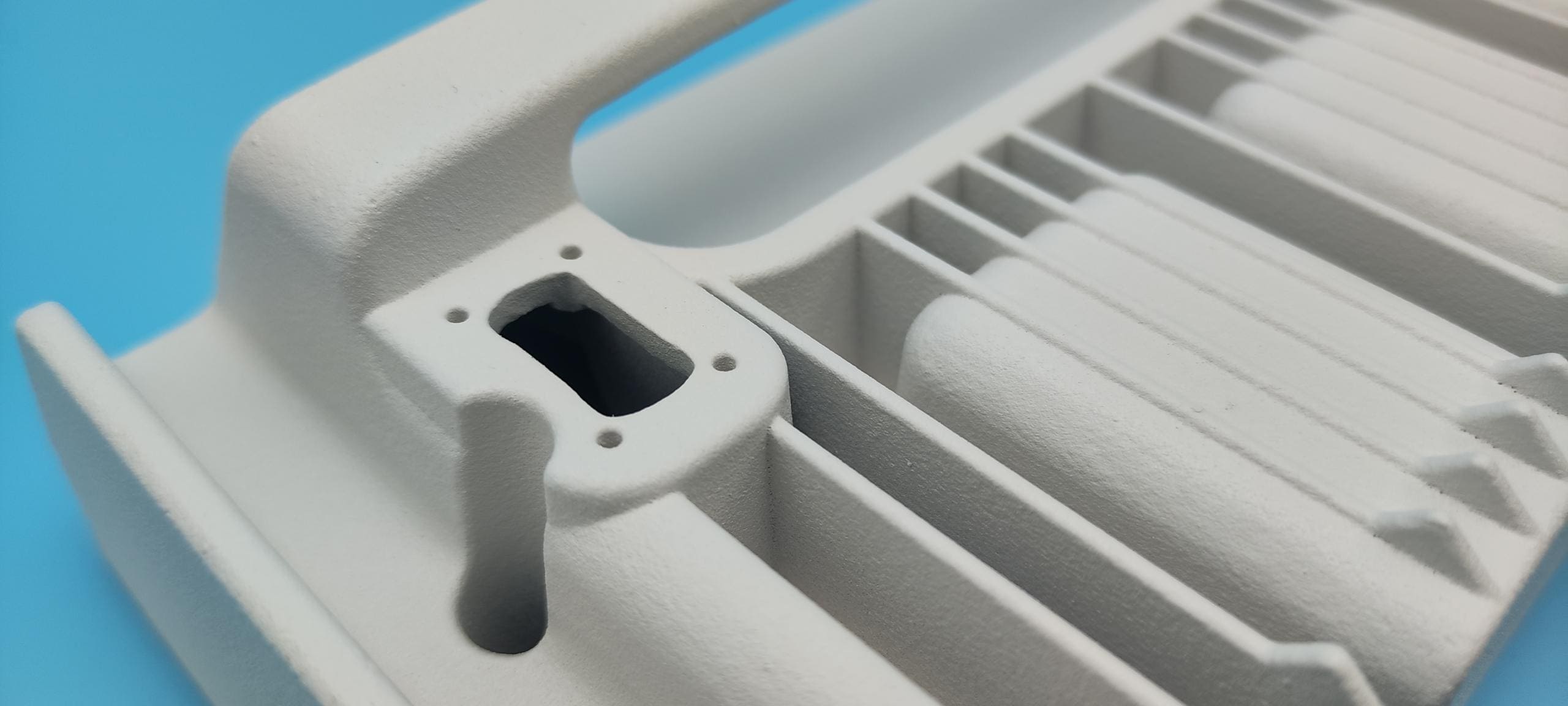

3DSPRO stepped in with a comprehensive 3D printing solution. Leveraging both metal and polymer additive manufacturing, the team delivered:

• Chassis and housings: Strong, lightweight, and corrosion-resistant, optimized for outdoor solar environments.

• Gaskets and seals: Produced with precision to ensure reliability in harsh conditions.

• Spare parts: Manufactured on demand, reducing inventory costs and ensuring rapid replacement when needed.

The result was a streamlined development cycle. Yotta Energy could test, iterate, and deploy components far faster than with traditional methods. The collaboration not only validated the technical feasibility of their designs but also demonstrated the scalability of additive manufacturing for renewable energy applications.

In this case study, metal 3D printing is a strategic enabler of clean energy innovation.

Image Copyright © 3DSPRO Limited. All rights reserved.

How Metal 3D Printing Accelerates Clean Energy Innovation

1. Speed-to-Market

• Rapid prototyping eliminates the need for costly tooling.

• Energy startups can move from CAD design to a functional part in days, not months.

• Faster iteration cycles mean faster innovation.

2. Complex Geometries

• Metal 3D printing enables designs impossible with traditional methods.

• Lattice structures reduce weight while maintaining strength—ideal for solar housings or wind turbine components.

• Conformal cooling channels improve thermal management in batteries, fuel cells, and turbines.

3. Material Performance

• High-performance alloys such as titanium, Inconel, and stainless steel withstand extreme heat, corrosion, and stress.

• Perfect for outdoor solar installations, high-temperature turbines, and hydrogen infrastructure.

4. Customization at Scale

• Each energy installation has unique requirements.

• Additive manufacturing allows for mass customization without cost penalties.

• Spare parts can be produced on demand, reducing downtime and inventory costs.

Image Copyright © 3DSPRO Limited. All rights reserved.

Cross-Sector Applications

While the Yotta Energy case study highlights the impact of metal 3D printing in solar, the potential extends across the entire clean energy ecosystem.

Wind Energy

• Lightweight turbine housings reduce structural loads.

• Custom brackets and connectors improve installation efficiency.

• On-demand repair parts minimize downtime in remote wind farms.

Hydrogen Economy

• Electrolyzer plates with intricate flow channels improve hydrogen production efficiency.

• Fuel cell components benefit from optimized geometries for better performance.

• Corrosion-resistant alloys extend the lifespan of hydrogen infrastructure.

Nuclear Energy

• Radiation-resistant components ensure safety and longevity.

• Additive manufacturing enables the production of legacy parts no longer available through traditional supply chains.

• Complex cooling systems can be optimized for efficiency and safety.

Energy Storage

• Porous metal lattices improve the performance of next-generation batteries.

• Thermal management components enhance safety and efficiency in grid-scale storage.

• Custom housings and connectors enable modular, scalable storage solutions.

Image Copyright © 3DSPRO Limited. All rights reserved.

Sustainability Advantage

Metal 3D printing offers significant sustainability benefits:

• Reduced material waste: Unlike subtractive methods, additive manufacturing builds parts layer by layer, using only the material required.

• Powder recycling: Unused metal powder can often be reclaimed and reused, further reducing waste.

• Localized production: Parts can be manufactured close to the point of use, reducing transportation emissions.

• Extended component lifecycles: On-demand spare parts reduce the need for overproduction and minimize landfill waste.

Image Copyright © 3DSPRO Limited. All rights reserved.

If you’re ready to accelerate your clean energy innovation, explore:

• The full Yotta Energy case study for a deeper look at how 3DSPRO supports renewable pioneers.

• 3DSPRO’s Metal 3D Printing Services, delivering precision, speed, and scalability for complex energy applications.

• Surface Finishing Services, ensuring that every part meets the highest standards of performance and durability.

The future of clean energy is being built today. With 3DSPRO as your partner, you can move from vision to reality—faster, smarter, and more sustainably.

COMMENTS

- Be the first to share your thoughts!