Definition and Printing Process Comparison

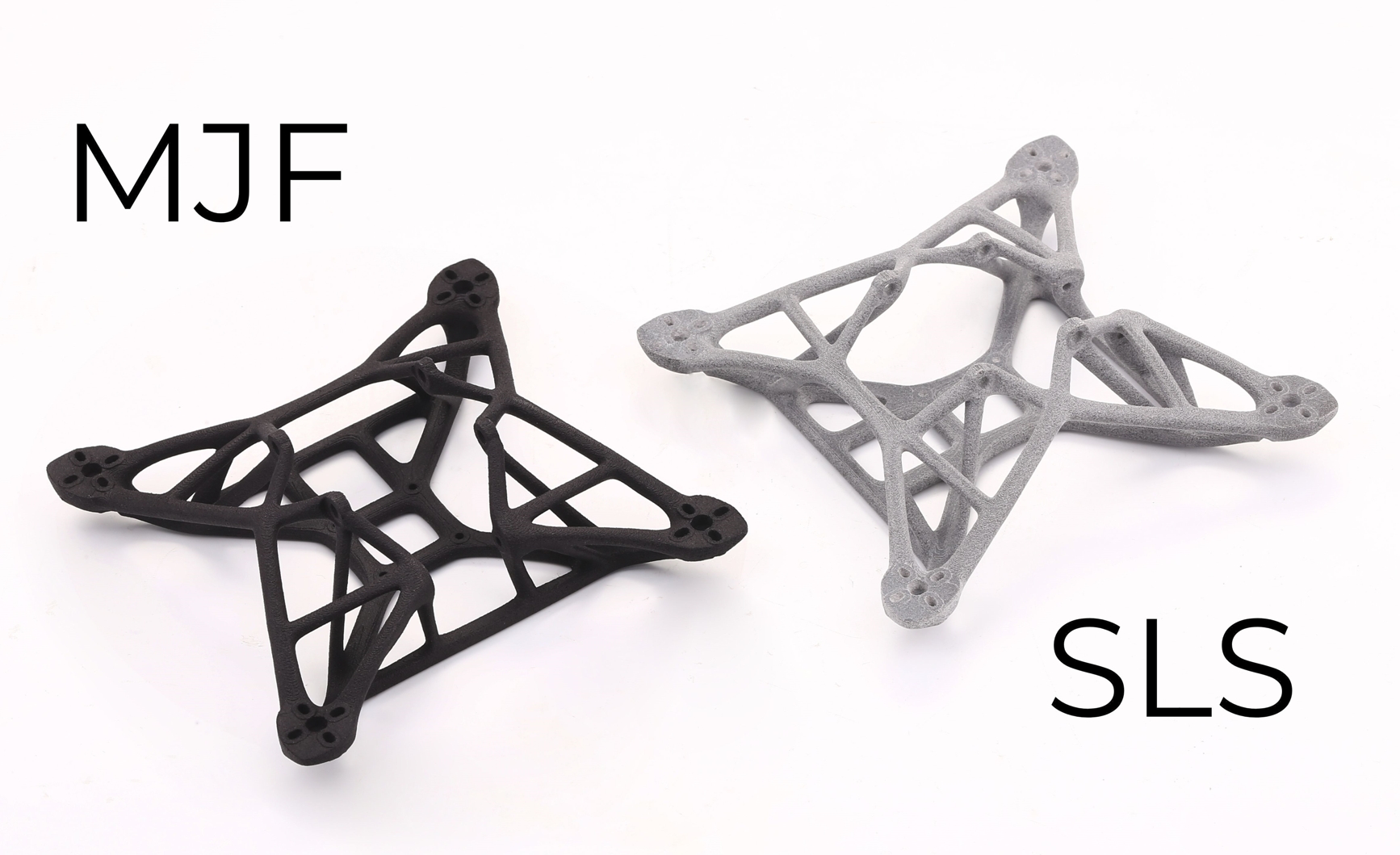

Two of the most prominent technologies in nylon 3D printing are Multijet Fusion (MJF) and Selective Laser Sintering (SLS). Both have unique properties and are suitable for different applications. Understanding their definitions and how their printing processes compare is essential for determining which is best for a specific use case.

MJF 3D Printing

Developed by HP, Multi Jet Fusion is a powder bed fusion process that creates parts layer by layer from a 3D digital model. It uses an inkjet array to deposit fusing agents onto a bed of nylon powder. These agents define the area that will be solidified by an infrared heat source, creating the desired part. MJF is known for its printing speed and ability to produce parts with consistent mechanical properties.

SLS 3D Printing

Selective Laser Sintering (SLS), on the other hand, also builds parts layer by layer by fusing a powder bed. However, it employs a high-powered laser to sinter the nylon powder, selectively fusing particles to form a solid structure. SLS is known for its ability to create strong, functional parts with complex geometries.

Comparison of Printing Processes

The primary difference between MJF and SLS lies in their heat sources: MJF uses infrared heat to fuse areas defined by its detailing and fusing agents, while SLS relies on a laser to sinter the powder. This distinction leads to variations in surface finish, detail, and mechanical properties.

MJF typically offers a slightly higher print resolution and better isotropic properties, making it ideal for smaller, functional parts. SLS, conversely, can utilize a broader range of materials and is often chosen for larger parts or visual prototypes.

Whether to use MJF or SLS depends on the specific requirements of the part being printed, such as detail, strength, and production volume. In the following sections, let's explore these two technologies in detail.

MJF Nylon vs. SLS Nylon

When evaluating MJF and SLS for nylon 3D printing, it's crucial to understand the material properties that each process imparts to the finished parts. Both technologies use Nylon, a versatile thermoplastic, but the outcomes can differ due to the distinct techniques of each method.

MJF Nylon Properties

MJF Nylon, specifically Nylon PA 12, is known for its toughness and chemical resistance, making it suitable for a wide range of applications. The MJF process enhances the material's isotropic mechanical properties, meaning the strength and durability are consistent regardless of the part's orientation. It is particularly beneficial for parts that will be subjected to multidirectional forces.

SLS Nylon Properties

SLS Nylon also exhibits high toughness and a good strength-to-density ratio. It can be easily dyed, which allows for a broader range of aesthetic options. However, SLS parts may show slight anisotropy in mechanical properties, meaning the strength could vary with the direction of the load. This factor is essential to consider for parts that need uniform strength throughout.

Compare the Performance of MJF Printed Parts to SLS Printed Parts

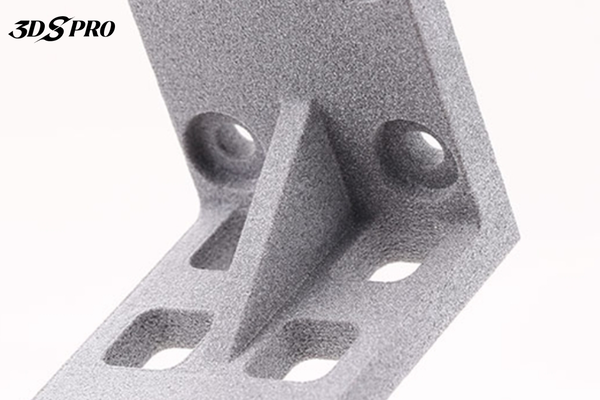

Dimensional Accuracy and Surface Finish

MJF is renowned for its high dimensional accuracy and smooth surface finish. The technology allows for fine details and a more refined surface, which can reduce the need for post-processing. It makes MJF ideal for applications where precision is paramount.

SLS, while also precise, tends to have a rougher surface finish due to the nature of the laser sintering process. However, this can be advantageous for certain applications where the texture is beneficial, or post-processing is planned to achieve the desired finish.

Mechanical Properties

MJF parts exhibit excellent isotropic mechanical properties, meaning their strength and durability are consistent in all directions. It is due to the uniform thermal control during the printing process, which ensures even fusing of the powder.

SLS parts, on the other hand, may display slight anisotropy, with variations in mechanical properties depending on the orientation of the part. However, SLS is still highly regarded for producing robust parts that can withstand functional testing and use.

Production Speed and Volume

When it comes to production speed, both technologies are comparable, but MJF has an edge in terms of throughput for larger production volumes. This is due to the nature of the MJF process, which can handle multiple parts simultaneously with efficiency.

SLS is well-suited for low to medium-volume production and can handle larger builds, making it a good choice for larger parts or when a higher number of parts is not required.

Material Utilization

MJF technology boasts a higher rate of powder recyclability, which can lead to cost savings and environmental benefits. The ability to reuse more material means less waste and lower material costs.

SLS has a lower rate of powder recyclability, which can increase material costs over time. However, the wide range of materials available for SLS printing can offset this, providing more options for specific application requirements.

Application Considerations

When deciding Multi Jet Fusion (MJF) and Selective Laser Sintering (SLS) for 3D printing with nylon, several application considerations should be taken into account to ensure the chosen method aligns with the project’s goals.

Design Complexity

Due to its high resolution and isotropic properties, MJF is well-suited for parts with intricate details and complex geometries. It can accurately produce fine features and internal channels that may be challenging for SLS.

Functional Requirements

For parts that require high durability and uniform strength, such as functional prototypes or end-use components, MJF’s consistent mechanical properties make it a strong candidate. SLS parts, while still robust, may require additional consideration for orientation during printing due to potential anisotropy.

Aesthetic Preferences

If color and finish are important, SLS offers more post-processing flexibility. Parts can be dyed in various colors, which is beneficial for consumer-facing products or parts that need to match specific branding guidelines.

Production Volume and Cost

MJF can be more cost-effective for larger production runs due to its faster build times and higher powder recyclability, which leads to significant savings in material costs over time. SLS might be more suitable for smaller batches or individual custom parts.

Material Selection

While both technologies primarily use Nylon 12, SLS can process a broader range of materials, including flexible options like TPU or glass-filled variants for added strength. This versatility can be crucial for applications requiring specific material characteristics.

Environmental Impact

MJF’s higher powder recyclability rate contributes to a more sustainable production process, reducing waste and potentially lowering the environmental footprint of manufacturing operations.

A thorough evaluation of these aspects will guide you to the most appropriate technology for their specific application needs.

COMMENTS

- Be the first to share your thoughts!